Phase change thermoregulation cement pitch composition concrete and preparation method thereof

A technology for asphalt concrete and cement asphalt, which is applied in the field of phase-change temperature-regulating cement-asphalt composite concrete and its preparation, can solve problems such as poor high-temperature stability of phase-change pavement materials, and achieves alleviation of urban heat island effect, simple process, and reduced The effect of road temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

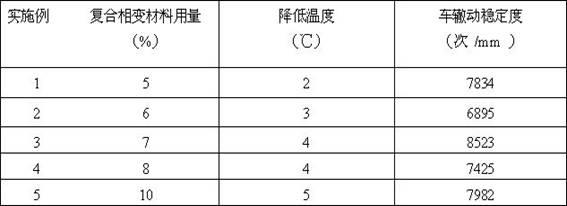

[0029] The phase-change temperature-adjusted cement-asphalt composite concrete is composed of large-pore asphalt concrete and cement mortar mixed with phase-change materials. In the large-pore concrete, the weight percentage of each raw material is: aggregate 88%, mineral powder 7%, modified 5% permanent asphalt; in the cement mortar, the weight percentage of each raw material is cement 40%, fine sand 20%, fly ash 7%, water 27%, expansion agent 0.7%, composite phase change material 5%, water reducing Agent 0.3%;

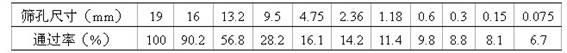

[0030] The crushing value of the aggregate is 10%, the needle flake content is 3%, and the gradation is shown in Table 1;

[0031] The slag powder is limestone slag powder, and meets the technical requirements for fillers in the "Technical Specifications for Construction of Highway Asphalt Pavement";

[0032] The modified asphalt is a high-viscosity TPS modified asphalt, and its viscosity at 60°C is 90,000 Pa.s;

[0033] The fine sand is river sand with a particle ...

Embodiment 2

[0043] Phase-change temperature-adjusted cement-asphalt composite concrete is composed of large-pore asphalt concrete and cement mortar mixed with phase-change materials. In large-pore concrete, the weight percentages of each raw material are: aggregate 90%, mineral powder 5.5%, modified 4.5% permanent asphalt; in the cement mortar, the weight percentage of each raw material is cement 42%, fine sand 17%, fly ash 6%, water 28%, expansion agent 0.7%, composite phase change material 6%, water reducing Agent 0.3%;

[0044] The crushing value of the aggregate is 10%, the needle flake content is 3%, and the gradation is shown in Table 1;

[0045] The modified asphalt is a high-viscosity TPS modified asphalt, and its viscosity at 60°C is 90,000 Pa.s;

[0046] The fine sand is river sand with a particle size of ≤0.6mm;

[0047] The fly ash is Class II fly ash, particle size ≤ 0.6mm;

[0048] Described expansion agent is UEA expansion agent;

[0049] The composite phase change mate...

Embodiment 3

[0056] The phase-change temperature-adjusted cement-asphalt composite concrete is composed of large-pore asphalt concrete and cement mortar mixed with phase-change materials. In the large-pore concrete, the weight percentage of each raw material is: aggregate 91%, mineral powder 5%, modified 4% permanent asphalt; in cement mortar, the weight percentage of each raw material is cement 43%, fine sand 15%, fly ash 5%, water 29%, expansion agent 0.6%, composite phase change material 7%, water reducing Agent 0.4%;

[0057] The crushing value of the aggregate is 10%, the needle flake content is 3%, and the gradation is shown in Table 1;

[0058] The modified asphalt is a high-viscosity TPS modified asphalt, and its viscosity at 60°C is 90,000 Pa.s;

[0059] The fine sand is river sand with a particle size of ≤0.6mm;

[0060] The fly ash is Class II fly ash, particle size ≤ 0.6mm;

[0061] Described expansion agent is UEA expansion agent;

[0062] The composite phase change materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com