Laminated metal plate as well as production method and production device thereof

A production method and technology of production equipment, applied in the field of materials, can solve problems such as poor product stability, instability, and unenvironmental protection, and achieve the effect of continuous industrial production, less dependence on the environment, and scientific production methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

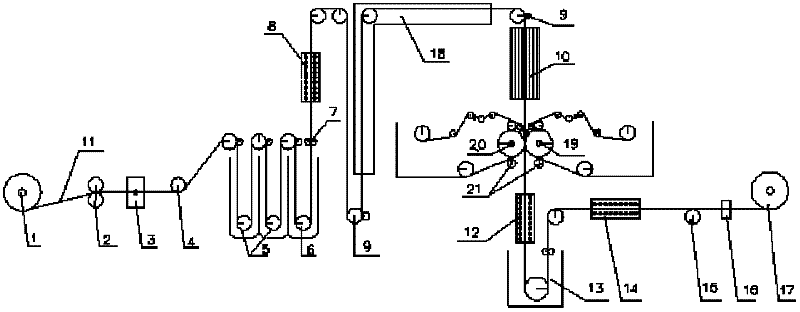

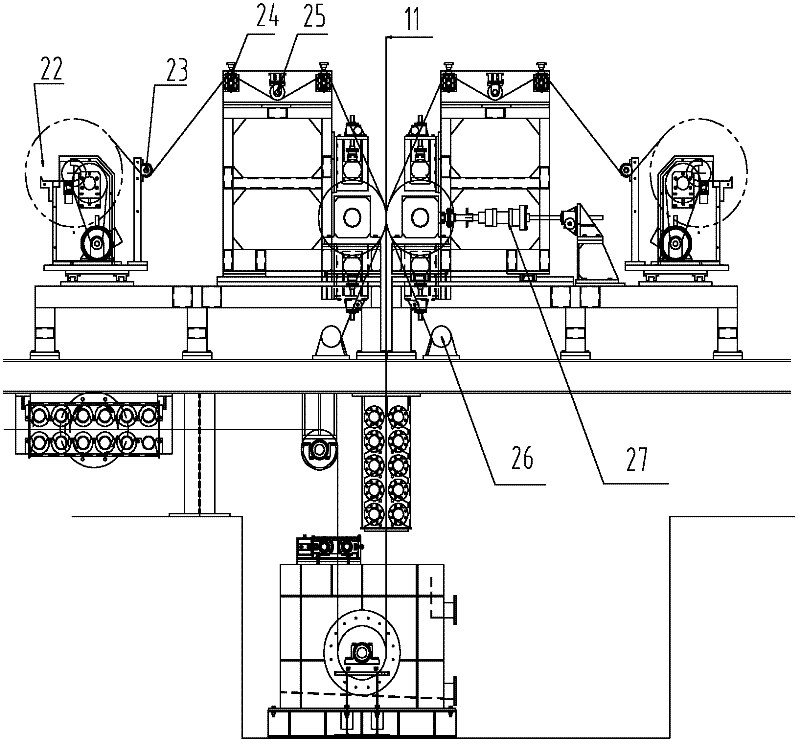

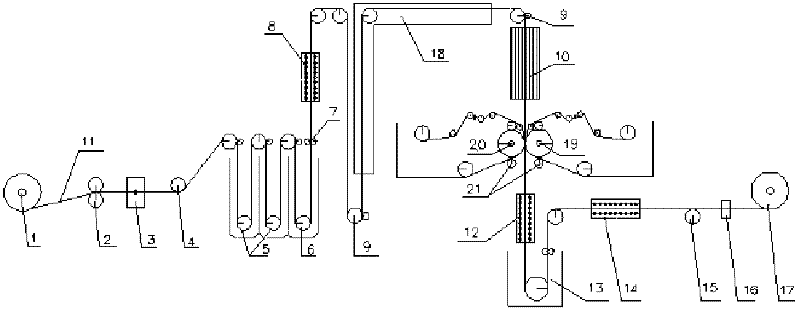

Image

Examples

Embodiment 1

[0054] This embodiment provides a film-coated metal plate, which includes a metal plate and a polyester film coated on its surface, and there is no adhesive between the metal plate and the polyester film. The polyester film used is polyethylene terephthalate, specifically, the polyester film used in this embodiment is the white film disclosed in Chinese Patent Application No. 200910259903.0, and its melting point is 230-260°C. The metal plate is chrome-plated cold-rolled steel sheet.

[0055] The production method of above-mentioned coated metal plate, comprises the following steps:

[0056] Heat the metal plate so that the temperature of the metal plate is higher than the melting point of the polyester film, that is, heated to 260-280°C; apply a linear pressure of 6kg / mm to the polyester film through the film covering device, so that the polyester film covers the metal plate One side; the side of the polyester film close to the metal plate is melted, and the side away from...

Embodiment 2

[0058] This embodiment provides a film-coated metal plate, which includes a metal plate and a polyester film coated on its surface, and there is no adhesive between the metal plate and the polyester film. The polyester film used is polyethylene terephthalate, specifically, the polyester film is a transparent film as described in Chinese patent application 200910223570.6, and its melting point is 210-260. The metal plate is chrome-plated cold-rolled steel sheet.

[0059] The production method of above-mentioned coated metal plate, comprises the following steps:

[0060] The metal plate is heated so that the temperature of the metal plate is equal to the melting point of the polyester film, that is, the metal plate is heated to 245° C.; the polyester film is applied with a linear pressure of 6 kg / mm through the film covering device, so that the polyester film is covered on the metal plate ( On both sides of the chrome-plated cold-rolled thin steel plate); the side of the poly...

Embodiment 3

[0078] The film-coated metal plate prepared in Example 2 is applied to the lid of the metal packaging can and the two-piece can product. Experiments prove that the film-coated metal plate has the advantages of strong adhesion and resistance to cooking.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com