Micro and fine machining method for material difficult to machine

A finishing and difficult-to-machine technology, applied in the field of compound precision and micro special machining, it can solve the problems of increasing the energy of electrolysis, uneven electrolysis, and increasing current density, so as to improve the localized machining performance and improve the process of machining gap. , Improve the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

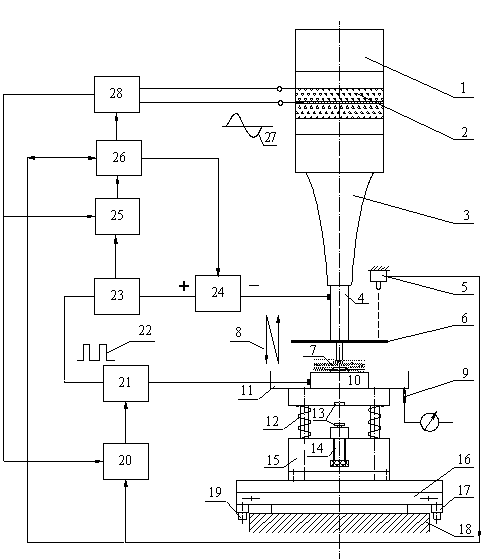

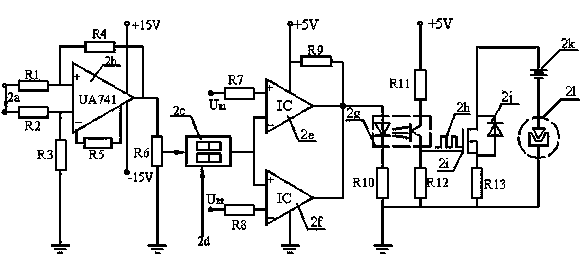

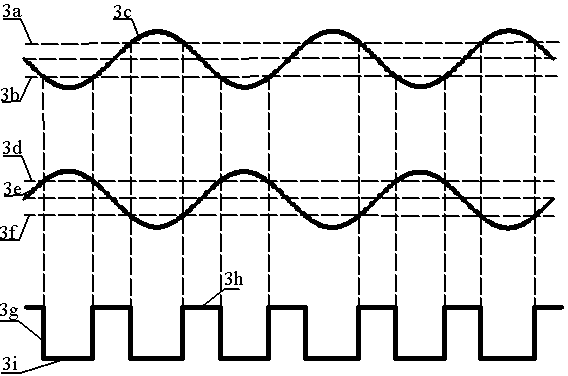

Method used

Image

Examples

example 1

[0057] Example 1: Fine discharge of square cone-shaped array of micro-pits on the surface of stainless steel 40Cr - electrolytic composite processing pulse power supply voltage amplitude 0V (full ultrasonic processing), 3V, 4V, 5V, frequency 5000Hz, duty ratio 5:5, system ultrasonic frequency The vibration resonance frequency is 17.32KHz, the ultrasonic amplitude is 0.05mm, the working fluid is 60% ethanol aqueous solution with 1% sodium nitrate, and 20-50 nanometer B4C is mixed in it, the contact static pressure between the workpiece and the electrode is 2.0N, and the processing time 3 minutes.

[0058] Composite ultrasonic frequency vibration fine discharge—the depth (i.e., efficiency) of electrolytic machining square cone micro-pit is significantly higher than that of single ultrasonic machining, the voltage amplitude increases, and the processing efficiency increases, but the gap increases due to electrolysis, and the pit size also increases. Among them, the accuracy and s...

example 2

[0059] Example 2: Carbide YBD151 micro-gear fine discharge-electrolytic composite machining DC power supply voltage amplitude 3V, system ultrasonic frequency vibration resonance frequency 17.46KHz, ultrasonic amplitude 0.09mm, contact static pressure between the workpiece and the fine cathode is 3.0N, The working solution is 60% ethanol aqueous solution with 0.5% sodium nitrate added, and 20-50 nanometers of B4C is mixed in it, and the processing time is 5 minutes.

[0060] Using a micro-electrode with an internal tooth-shaped hole, on a high wear-resistant matrix composite wear-resistant coating cemented carbide YBD151 material, the involute micro-gear with the number of teeth 22, the modulus 0.20mm, and the pressure angle 20o is nested. The thickness of the micro-gear is 0.30mm, the precision of the involute tooth shape can reach 0.001mm, and the roughness Ra of the tooth surface is 0.20μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com