Self-expanding ice-cream and production method thereof

A technology of ice cream and expansion rate, applied in frozen desserts, food science, applications, etc., can solve problems affecting product dryness, poor formability, inconvenient filling, etc., and achieve good texture and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

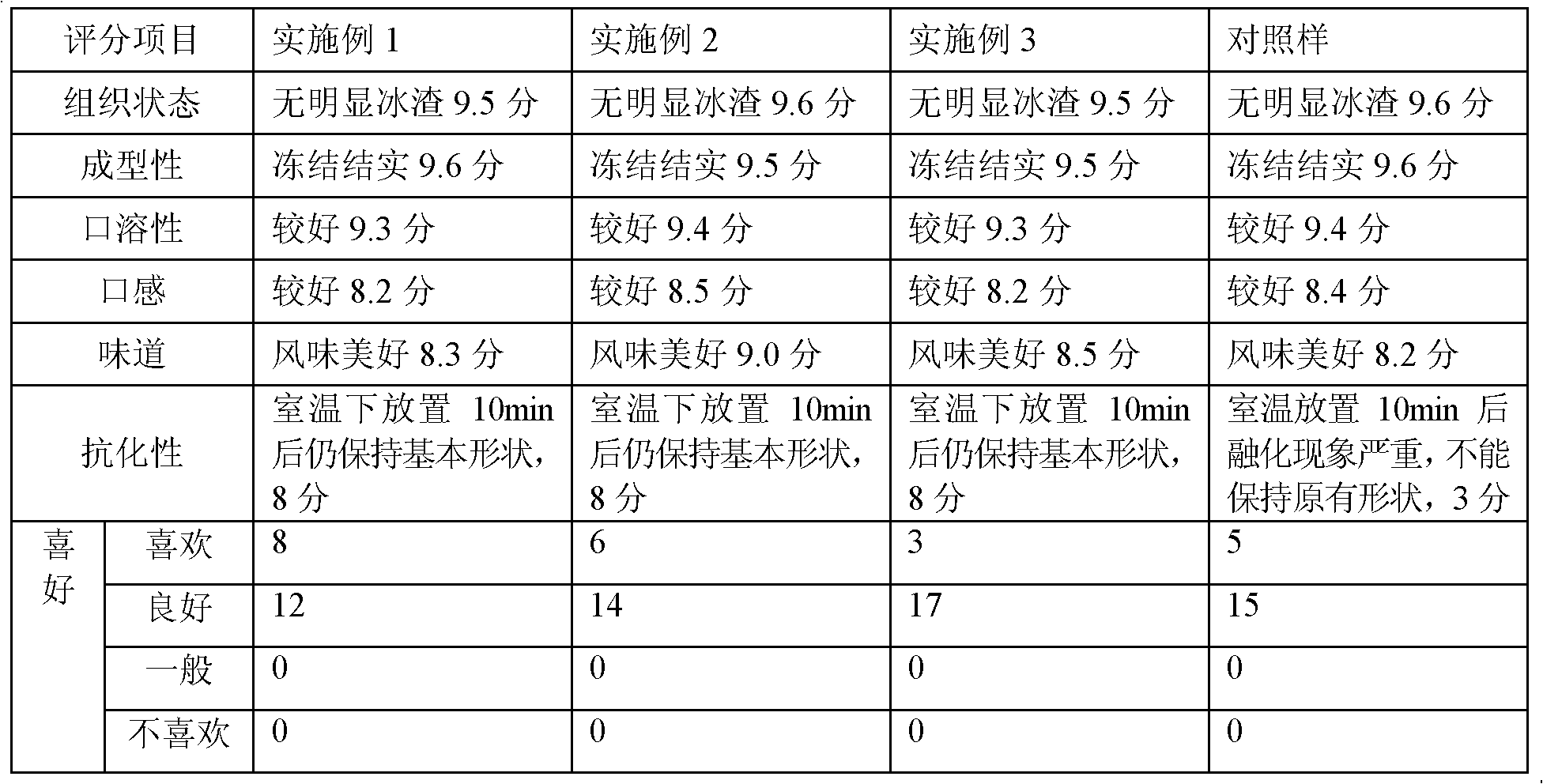

Examples

Embodiment 1

[0040] The formula of the ice cream of the present embodiment is:

[0041] White sugar 5%, cream (milk fat content about 38%) 52%, blueberry jam (dry matter content about 50%) 38.5%, 14E gelatin 1%, sodium alginate 2.5‰, locust bean gum 0.2‰, gellan gum 2.5‰, xanthan gum 0.2‰, water balance.

[0042] The performance of each raw material meets the requirements of relevant quality standards.

[0043] The production method of the ice cream of the present embodiment is carried out according to the following steps:

[0044] (1) Dry mix white granulated sugar, thickener, and water-retaining agent evenly, dissolve the ingredients in water, mix with blueberry jam, and stir evenly; the mixed solution is sterilized at 85°C for 30s; cooled to room temperature;

[0045] (2) Whipping the cream at 20°C and a whipping speed of 250 rpm, the volume gradually expands, reaching an expansion rate of about 85%;

[0046] (3) Under the condition of slow stirring (≤100rpm), add the sugar, thickene...

Embodiment 2

[0051] The formula of the ice cream of the present embodiment is:

[0052] White sugar 10%, cream (milk fat content about 32%) 75%, milk powder 1.5%, gelatin 2%, locust bean gum 0.2‰, guar gum 4‰, xanthan gum 0.2‰, the balance water.

[0053] The performance of each raw material meets the requirements of relevant quality standards.

[0054] The production method of the ice cream of the present embodiment is carried out according to the following steps:

[0055] (1) Dry mix white granulated sugar, thickener, water retaining agent, and milk powder evenly, dissolve the ingredients in water, stir and mix; then perform homogenization, the homogenization temperature is 80°C, and the homogenization pressure is 22MPa; the homogenized mixture is processed Sterilize at 85°C for 30s; cool the mixed material to normal temperature after sterilization;

[0056] (2) Whipping the cream at 25°C and a whipping speed of 200 rpm, the volume gradually expands to an expansion rate of about 80%; ...

Embodiment 3

[0060] The formula of the ice cream of the present embodiment is:

[0061] White sugar 14%, cream (milk fat content about 45%) 50%, cheese powder 1%, 14E gelatin 1%, locust bean gum 0.3‰, sodium alginate 2‰, xanthan gum 2‰, the balance water.

[0062] The performance of each raw material meets the requirements of relevant quality standards.

[0063] The production method of the ice cream of the present embodiment is carried out according to the following steps:

[0064] (1) Dry mix white sugar, thickener, water retaining agent, and cheese powder evenly, dissolve the ingredients in water, stir and mix; then perform homogenization, the homogenization temperature is 75°C, and the homogenization pressure is 20MPa; the mixed material after homogenization Sterilize at 85°C for 30s; cool the sterilized mixture to normal temperature;

[0065] (2) Whipping the cream at 20°C and a whipping speed of 300 rpm, the volume gradually expands, reaching an expansion rate of about 65%;

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com