Method for processing cultivation material for edible fungi

A cultivation material treatment and cultivation material technology, applied in botany equipment and methods, applications, horticulture, etc., can solve the problems of increasing the growth and maturation time of edible fungi, prolonging the production cycle, etc., so as to speed up capital turnover and improve production Efficiency and the effect of increasing economic income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1. Preparation of Ganoderma lucidum cultivation material

[0015] 1) Preparation of puffed raw materials: According to the original cultivation material formula of Ganoderma lucidum, mix the main raw materials in the cultivation material (including sawdust, cottonseed hulls, and bran), then take out 30% of the mixed main raw materials and grind them, and then add water , adjusting the moisture content of the main raw material after taking out and mixing to 20% to obtain puffed raw material.

[0016] 2) Extrusion and puffing: first set the working parameters of the extrusion puffing machine, and after the extrusion puffing machine reaches the set working parameter requirements, put the puffed raw materials obtained in step 1) into the extrusion puffing machine for extrusion Expanding to obtain the main raw material after expansion.

[0017] Wherein, the extruder is a twin-screw extruder, and the working parameters of the extruder are as follows:

[0018] Wor...

Embodiment 2

[0024] Embodiment 2. The preparation of Bailing mushroom cultivation material

[0025] 1) Preparation of puffed raw materials: According to the original cultivation material formula of Bailing mushroom, the main raw materials in the cultivation material (including cottonseed husk, bran, cornmeal) are mixed, and then 20% of the mixed main raw materials are taken out and pulverized, Then add water, adjust the water content of the main raw material after taking out and mixing to 12% to obtain puffed raw material.

[0026] 2) Extrusion and puffing: first set the working parameters of the extrusion puffing machine, and after the extrusion puffing machine reaches the set working parameter requirements, put the puffed raw materials obtained in step 1) into the extrusion puffing machine for extrusion Expanding to obtain the main raw material after expansion.

[0027] Wherein, the extruder is a twin-screw extruder, and the working parameters of the extruder are as follows:

[0028] W...

Embodiment 3

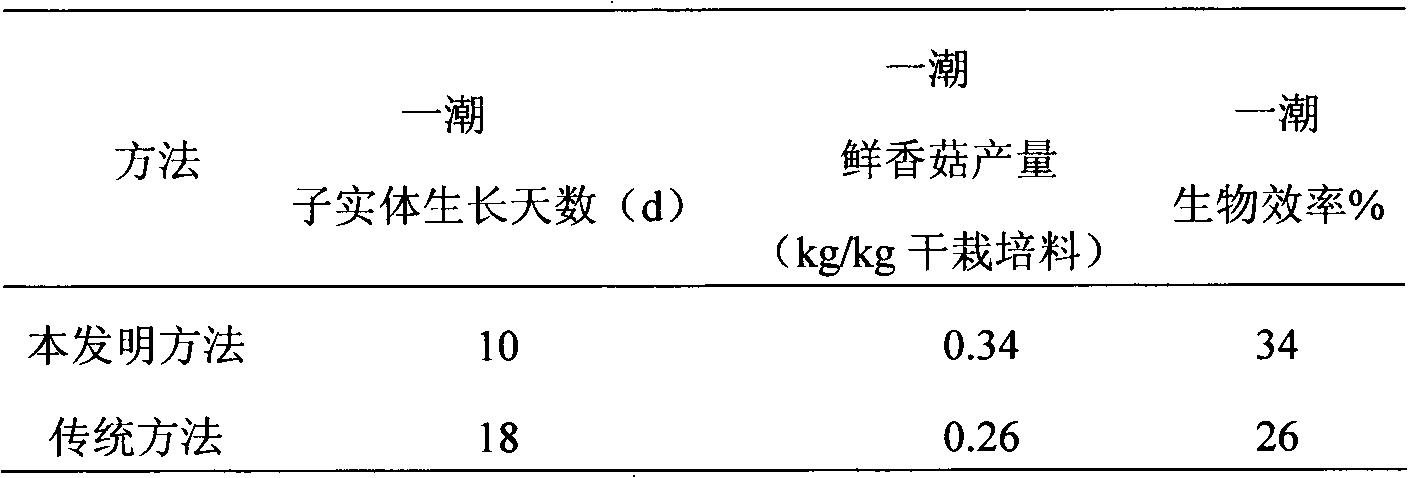

[0034] Embodiment 3. the preparation of mushroom cultivation material

[0035] 1) Preparation of puffed raw materials: According to the original cultivation material formula of shiitake mushrooms, mix the main raw materials (including sawdust and bran) in the cultivation material, then take out 50% of the mixed main raw materials and grind them, then add water, and take out The moisture content of the mixed main raw materials is adjusted to 35% to obtain puffed raw materials.

[0036] 2) Extrusion and puffing: first set the working parameters of the extrusion puffing machine, and after the extrusion puffing machine reaches the set working parameter requirements, put the puffed raw materials obtained in step 1) into the extrusion puffing machine for extrusion Expanding to obtain the main raw material after expansion.

[0037] Wherein, the extruder is a twin-screw extruder, and the working parameters of the extruder are as follows:

[0038] Working parameters of twin-screw ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com