Digital high-frequency and high-voltage power supply device of electron beam welding machine and control method thereof

A high-frequency high-voltage power supply and electron beam welding technology, which is applied to electron beam welding equipment, output power conversion devices, electrical components, etc. The effect of reducing quality and physical examination, small output voltage ripple, and fast fault protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

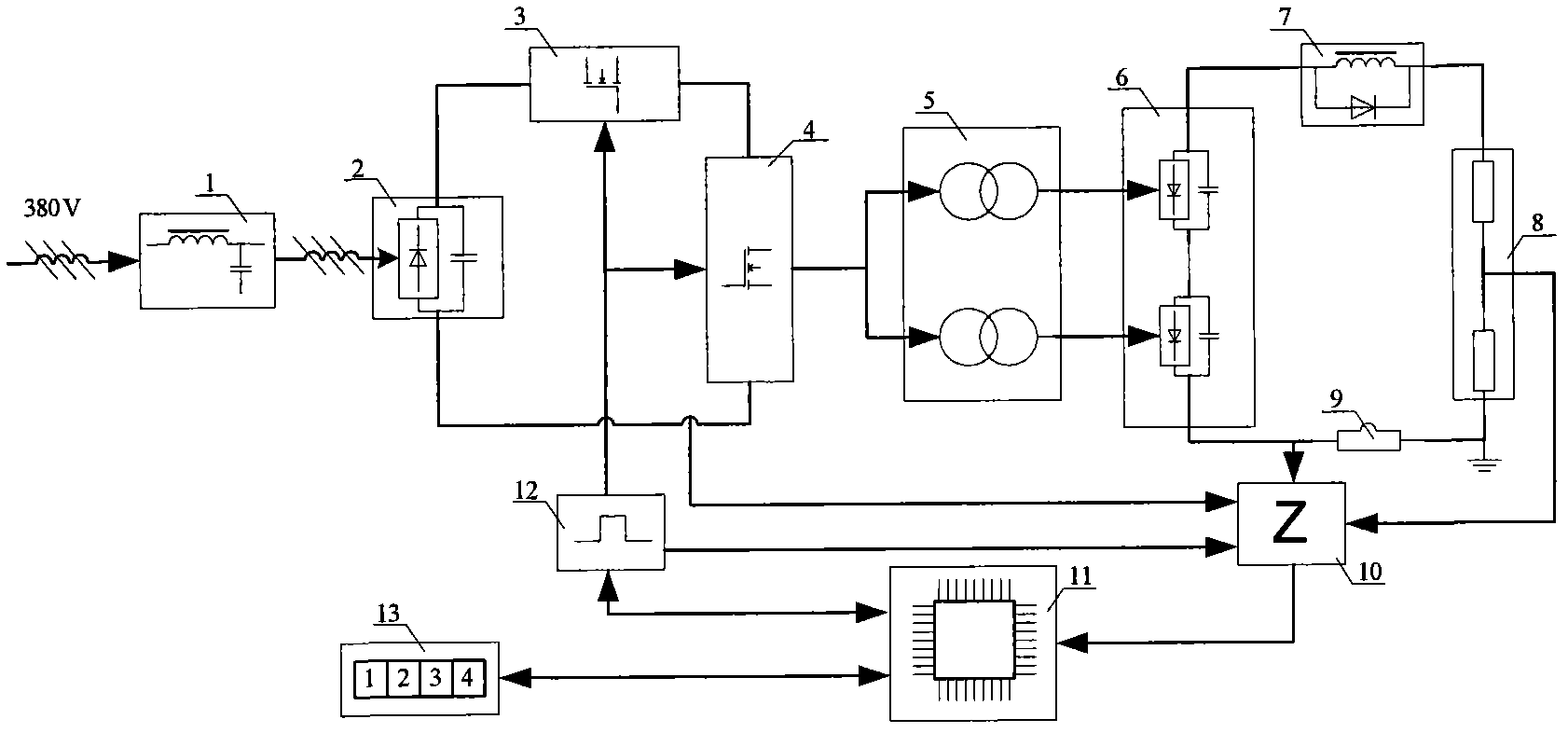

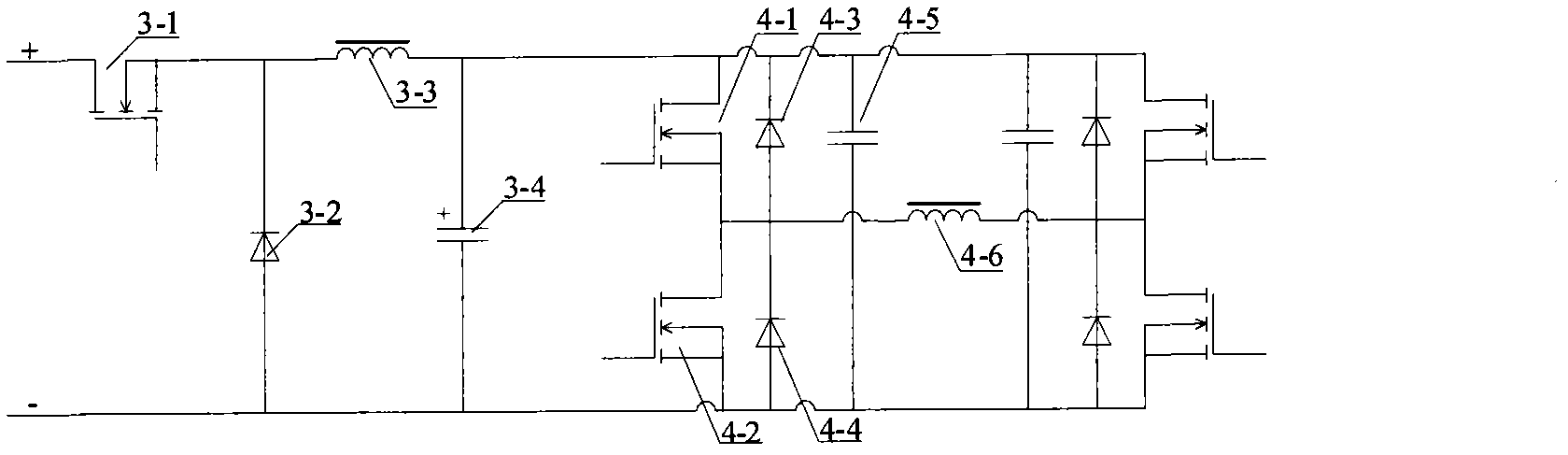

[0027] The digitized high-frequency high-voltage power supply device of the electron beam welding machine of the present embodiment, such as figure 1 As shown, it is mainly composed of grid filter 1, input rectification filter unit 2, high-frequency chopper voltage regulation unit 3, high-frequency inverter unit 4, high-frequency high-voltage transformer 5, high-frequency rectification filter unit 6, high-voltage discharge choke unit 7. High-voltage sampling unit 8, electron beam current sampling resistor 9, signal processing and fault synthesis unit 10, digital controller 11, drive circuit unit 12, and human-computer interaction unit 13.

[0028] The input terminal of the grid filter 1 is connected to the three-phase 380V grid, and its output is sent to the AC input side of the rectifier bridge in the input rectifier filter unit 2 . The power grid filter 1 is used to cut off the transmission path of electromagnetic interference (EMI).

[0029] The straight direct current out...

Embodiment 2

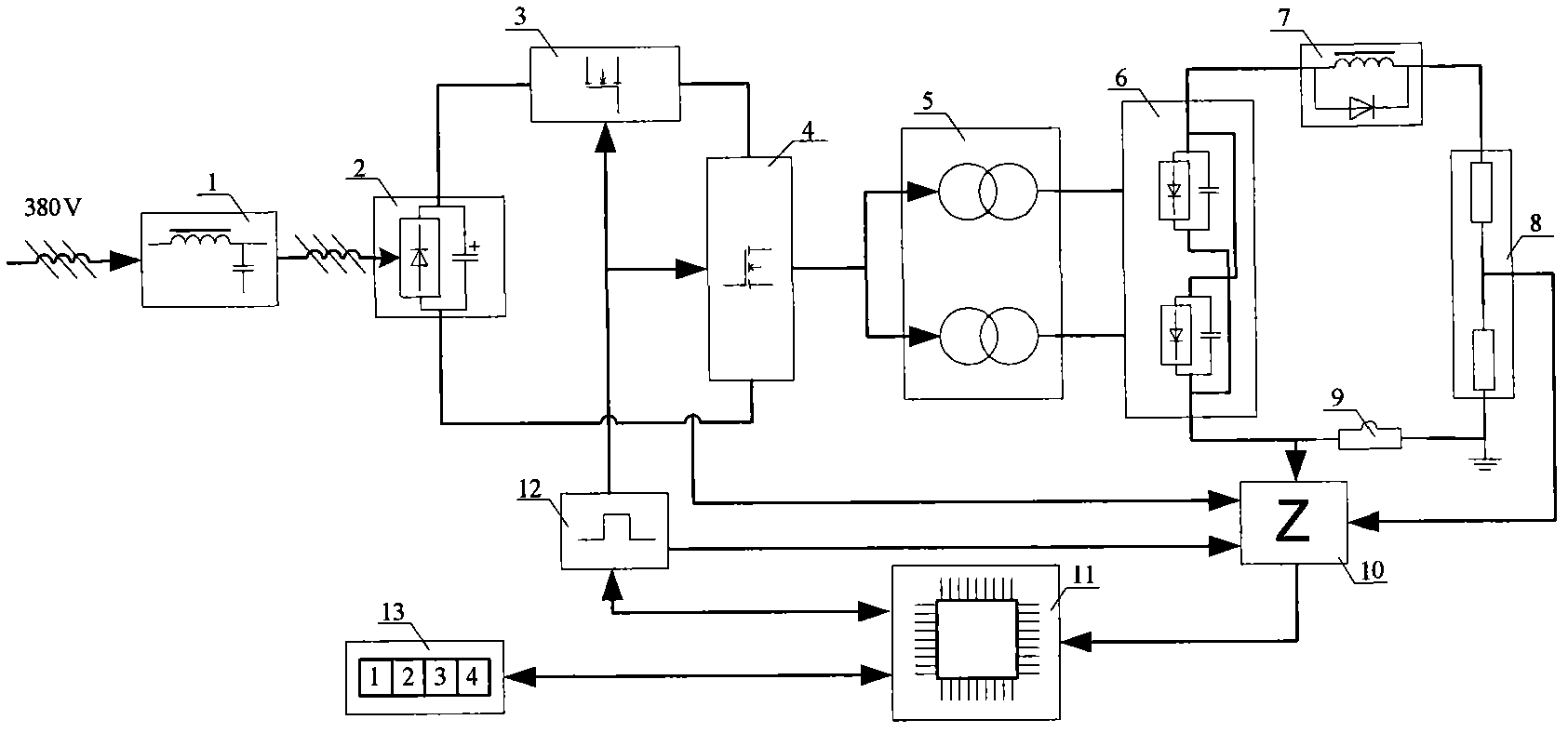

[0047] The digitized high-frequency high-voltage power supply device of the electron beam welding machine of the present embodiment, such as image 3 As shown, the difference from Embodiment 1 is that the four high-voltage rectifier bridges of the high-frequency rectification and filtering unit 6 are output in parallel (the embodiment 1 is a series output), while other parts are identical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com