Hydrated-structured SnO2 (stannic oxide)/IrO2 (iridium oxide) xH2O oxide film electrode material and preparation method for same

An oxide thin film, iro2 xh2o technology, applied in circuits, capacitors, electrical components, etc., can solve the problems of capacitance storage capacity attenuation, gap, and insufficient stability of capacitors, and achieve good capacitance performance and simple preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

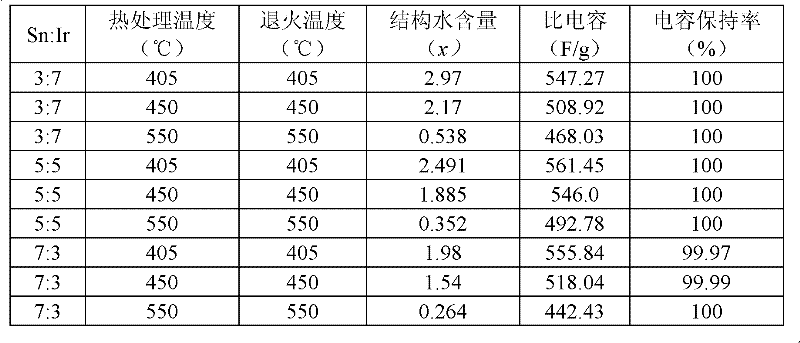

Examples

Embodiment Construction

[0016] The following descriptions are only preferred embodiments of the present invention, and all equivalent changes and modifications made according to the patent scope of the present invention shall fall within the scope of the present invention.

[0017] The present embodiment selects tin tetrachloride and chloroiridic acid as metal precursors, and tin tetrachloride and chloroiridic acid are dissolved to a volume ratio of 1: 1 in ethanol-isopropanol mixed solvent, so that the amount of total metal ions is 0.4mol / L. Add the hydrochloric acid of 35ml in every liter of solution, object is to prevent the hydrolysis of metal ion, add the hydrogen peroxide of 30ml in addition, effect is to make iridium ion and tin ion in the solution keep in the high valence state, through fully stirring, form transparent precursor solution.

[0018] The above-mentioned precursor solution is painted on the surface of titanium with a brush, then dried and solidified under an infrared lamp, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com