Method for forecasting retention time of gas chromatography under temperature programming after shortening of chromatographic column

A technology of retention time and temperature programming, applied in the field of chromatographic analysis, can solve problems such as high cost, inability to be widely used, and great differences in measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

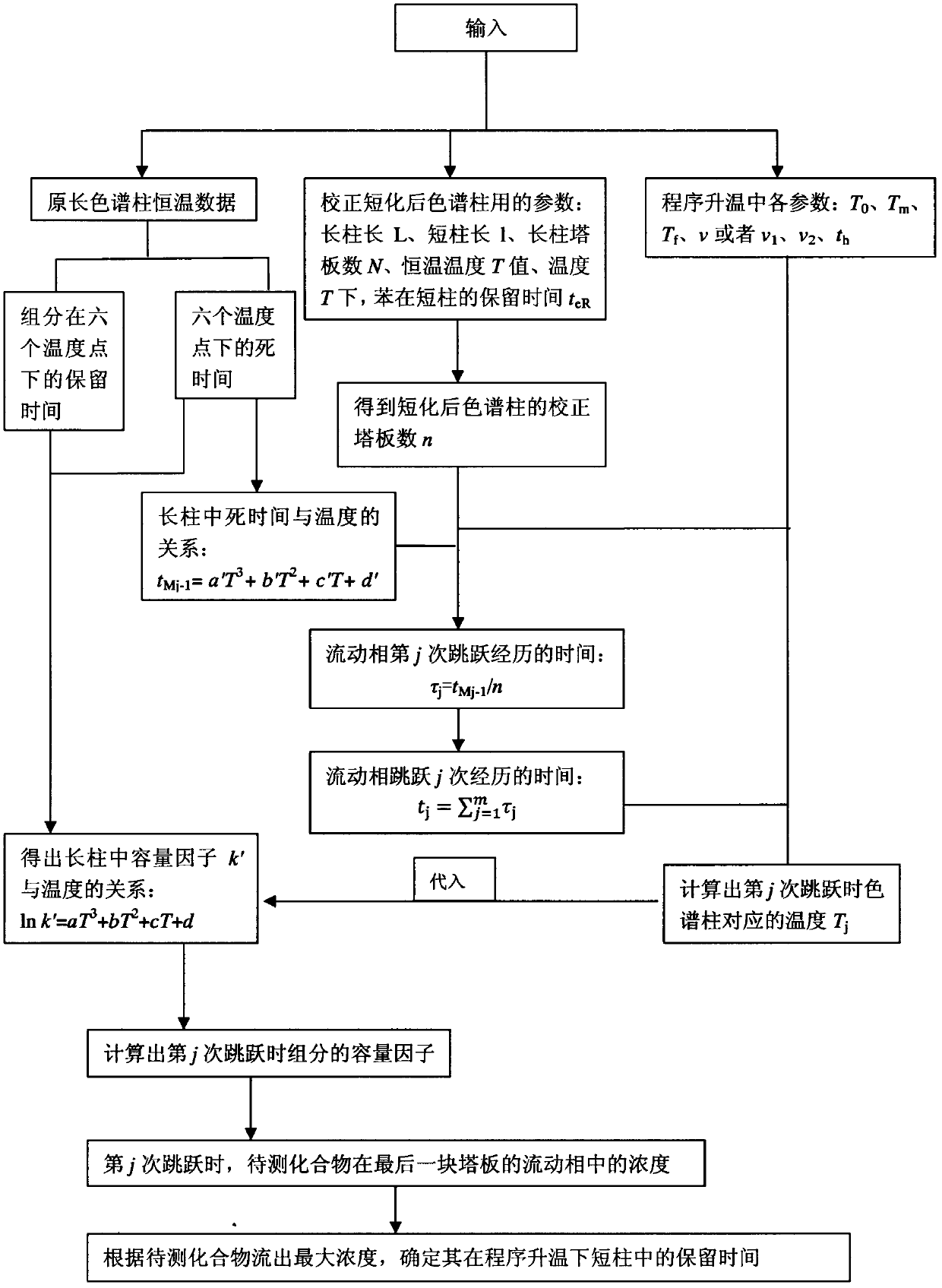

Method used

Image

Examples

Embodiment 1

[0111] Instruments: HP6890 gas chromatograph, hydrogen flame ionization detector, 6890 gas chromatograph workstation;

[0112] Chromatographic column: non-polar HP-5 (5% phenylmethyl polysiloxane) column;

[0113] Original length, HP-5 (Crosslinked 5% PH ME Siloxane, 30m×0.32mm×0.25μm);

[0114] After shortening, HP-5 (Crosslinked 5% PH ME Siloxane, 22m×0.32mm×0.25μm);

[0115] Conditions: The temperature of the detector is 250°C, and the temperature of the injection port is 250°C;

[0116] Carrier gas: use high-purity nitrogen gas (purity not less than 99.999%), constant flow operation mode, that is, the carrier gas is at the outlet of the column, and the mass flow rate is kept constant at 1ml / min;

[0117] Injection method: split injection, the split ratio is 50:1, each injection volume is 0.2μl, the initial concentration C M00 = 1 μg / ml;

[0118] Programmed heating conditions: Programmed temperature start temperature T 0 =30°C, heating rate v=5°C / min, termination tempe...

Embodiment 2

[0140] The process and condition of the present embodiment are identical with embodiment 1, and difference is:

[0141] Programmed heating conditions: Programmed temperature start temperature T 0 =30°C, heating rate v=25°C / min, termination temperature T f = 250°C;

[0142] (1) only need to change the parameter value of the programmed temperature rise rate of the input of step (nine) in embodiment 1 into temperature rise rate v=25 ℃ / min; All the other parameter values and prediction process are identical with embodiment 1;

[0143] (2) In order to verify the predicted value, it is necessary to start temperature T at the programmed temperature 0 =30°C, heating rate v=25°C / min, termination temperature T f =250°C, measure the real retention time of the three components on the shortened 22m HP-5 chromatographic column.

[0144] The error analysis between the predicted value and the measured value of the three substances under the above-mentioned programmed temperature rise cond...

Embodiment 3

[0148] The process and condition of the present embodiment are identical with embodiment 1, and difference is:

[0149] Samples: butyric acid, formaldehyde, heptane, methane, benzene;

[0150] (1) the process of step (1) in embodiment 1 is exactly the same;

[0151] (2) the process of step (2) in embodiment 1 is exactly the same;

[0152] (3) Respectively call the retention times of formaldehyde, heptane and standard substance benzene in the original length of 30m HP-5 column at 30°C, 50°C, 100°C, 150°C, 200°C and 250°C at six temperature points, they are respectively corresponds to:

[0153] 3.31min, 3.04min, 2.63min, 2.36min, 2.17min and 2.01min;

[0154] 8.43min, 5.17min, 3.00min, 2.46min, 2.19min and 2.01min;

[0155] 6.74min, 4.53min, 2.89min, 2.41min, 2.17min and 2.00min;

[0156] Because the retention time of butyric acid at low temperature is longer than 1 hour, the analysis time is too long, so only five temperatures of 50°C, 100°C, 150°C, 200°C and 250°C for but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com