Device for measuring density and flow rate of supercritical cracking product of hydrocarbon fuel, and measurement method thereof

A flow rate measurement device and pyrolysis product technology, which can be used to determine the specific gravity by measuring the pressure difference and measure the fluid velocity by using the pressure difference, and can solve the problems that the orifice flowmeter cannot adapt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

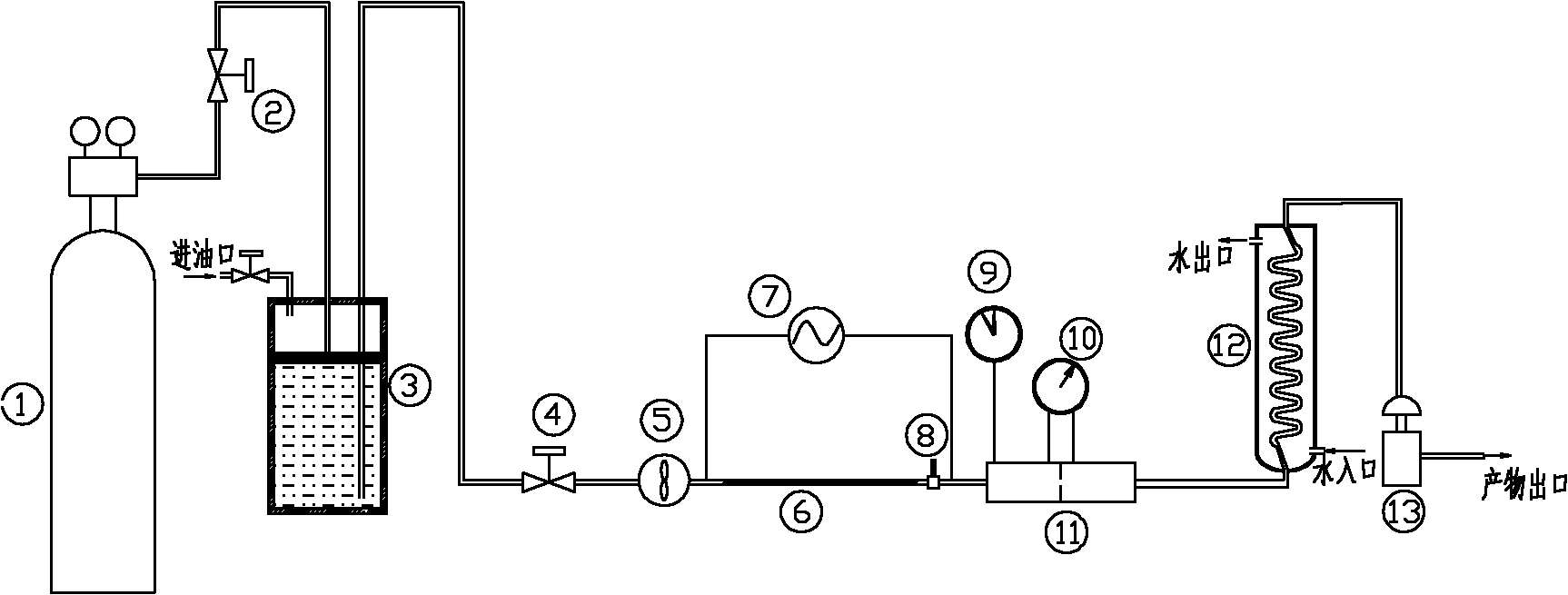

[0058] Such as figure 1 As shown, the device for measuring the density and flow velocity of supercritical cracking products of hydrocarbon fuels is connected by a pressurized gas source 1 through a needle valve 2 and an oil storage tank 3, and the oil storage tank passes through a flow regulating valve 4, a mass flow meter 5 and a heating pipe 6 connection, the heating pipe is connected to the orifice pressure taking device 11, and the orifice pressure taking device is connected to the back pressure valve 13 through the condenser 12.

[0059] The orifice pressure taking device 11 is provided with a differential pressure transmitter 10, the orifice pressure taking device 11, a pressure gauge 9 and a thermocouple 8 are arranged at the front end, and the orifice diameter of the orifice pressure taking device is 1.5-5mm.

[0060] The heating tube is connected to the AC power supply 7.

[0061] An oil inlet is established on the oil storage tank 3, and an oil outlet is established...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com