Cement-based intelligent composite material strain sensor and preparation method thereof

A strain sensor and composite material technology, applied in the field of sensors, can solve the problems of sensor strength reduction and electrical performance deterioration, and achieve the effects of avoiding electrical performance deterioration, improving interface bonding, and increasing the range of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

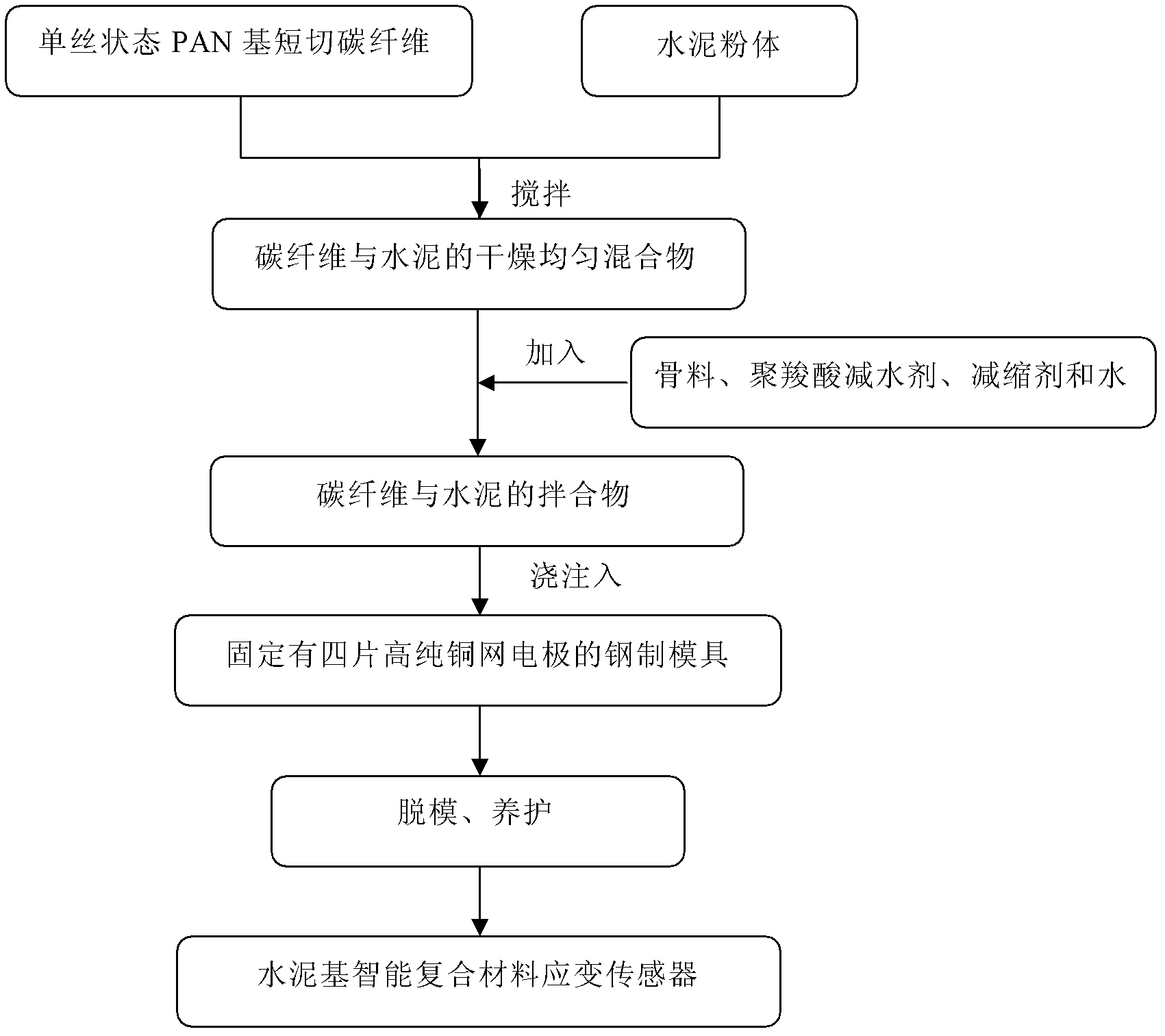

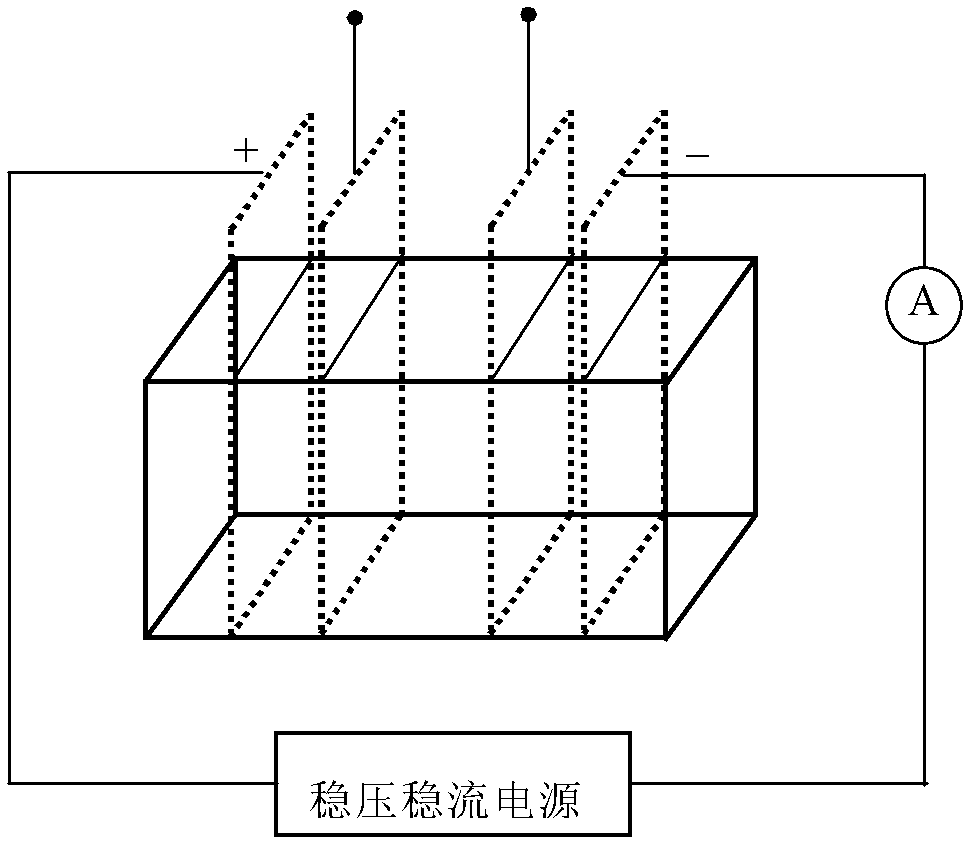

[0036] refer to figure 1 , figure 2 , a cement-based intelligent composite material strain sensor, composed of carbon fiber cement basic intelligent composite material and four parallel high-purity copper mesh electrodes arranged on the composite material, the aperture of the high-purity copper mesh is greater than 2mm, and the composite material is The mixture of PAN-based chopped carbon fiber and Portland cement with a mass ratio of 0.001:1, and the shape of the strain sensor is a cuboid.

[0037] Its preparation process is as follows:

[0038] First, prepare a steel mold with a cuboid cavity, and fix four high-purity copper meshes perpendicular to the longest side of the cuboid, parallel and symmetrical to each other in the mold.

[0039] Then, according to the mass ratio of 0.001:1, take PAN-based chopped carbon fiber and Portland cement, and use a high-speed mixer with crossed rubber blades to disperse the PAN-based chopped carbon fiber into a monofilament state, and t...

Embodiment 2

[0045] refer to figure 1 , figure 2 , a cement-based intelligent composite material strain sensor, composed of carbon fiber cement basic intelligent composite material and four parallel high-purity copper mesh electrodes arranged on the composite material, the aperture of the high-purity copper mesh is greater than 2mm, the composite material mainly It is composed of PAN-based chopped carbon fiber with a mass ratio of 0.004:1:0.5, Portland cement mixture and aggregate. The aggregate is quartz sand or a mixture of quartz sand with reasonable gradation in various particle size ranges. The shape of the strain sensor is cuboid.

[0046] Its preparation process is as follows:

[0047] First, prepare a steel mold with a cuboid cavity, and fix four high-purity copper meshes perpendicular to the longest side of the cuboid, parallel and symmetrical to each other in the mold.

[0048] Then, according to the mass ratio of 0.004:1:0.5, take PAN-based chopped carbon fiber, portland cem...

Embodiment 3

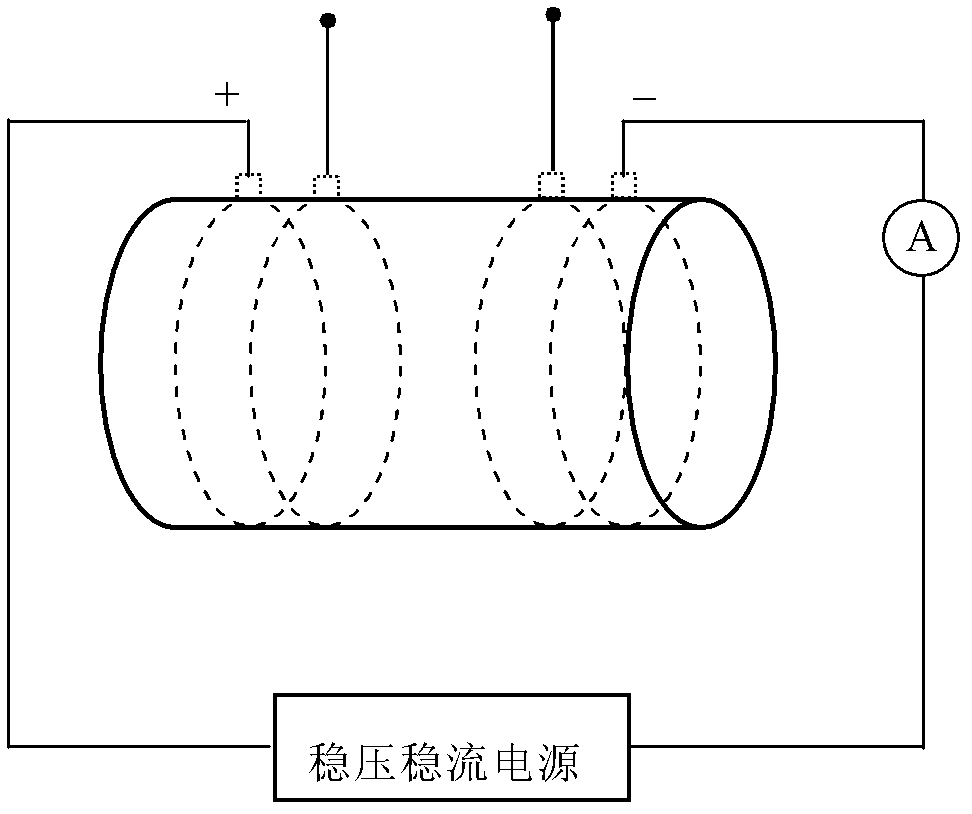

[0054] refer to figure 1 , image 3 , a cement-based intelligent composite material strain sensor, composed of carbon fiber cement basic intelligent composite material and four parallel high-purity copper mesh electrodes arranged on the composite material, the aperture of the high-purity copper mesh is greater than 2mm, and the composite material is The mixture of PAN-based chopped carbon fiber and Portland cement with a mass ratio of 0.006:1, and the shape of the strain sensor is a cylinder.

[0055] Its preparation process is as follows:

[0056] First, prepare a steel mold with a cylindrical cavity, and fix four pieces of high-purity copper mesh perpendicular to the generatrix of the cylinder, parallel and symmetrical to each other in the mold.

[0057] Then, according to the mass ratio of 0.006:1, take PAN-based chopped carbon fiber and Portland cement, and use a high-speed mixer with crossed rubber blades to disperse the PAN-based chopped carbon fiber into a monofilamen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com