Extended integral flat heat pipe at condensation end

A technology of flat heat pipe and condensing end, which is applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of reducing the heat dissipation efficiency of radiators, achieve the effect of solving high heat flow problems, simplifying the processing process, and improving heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

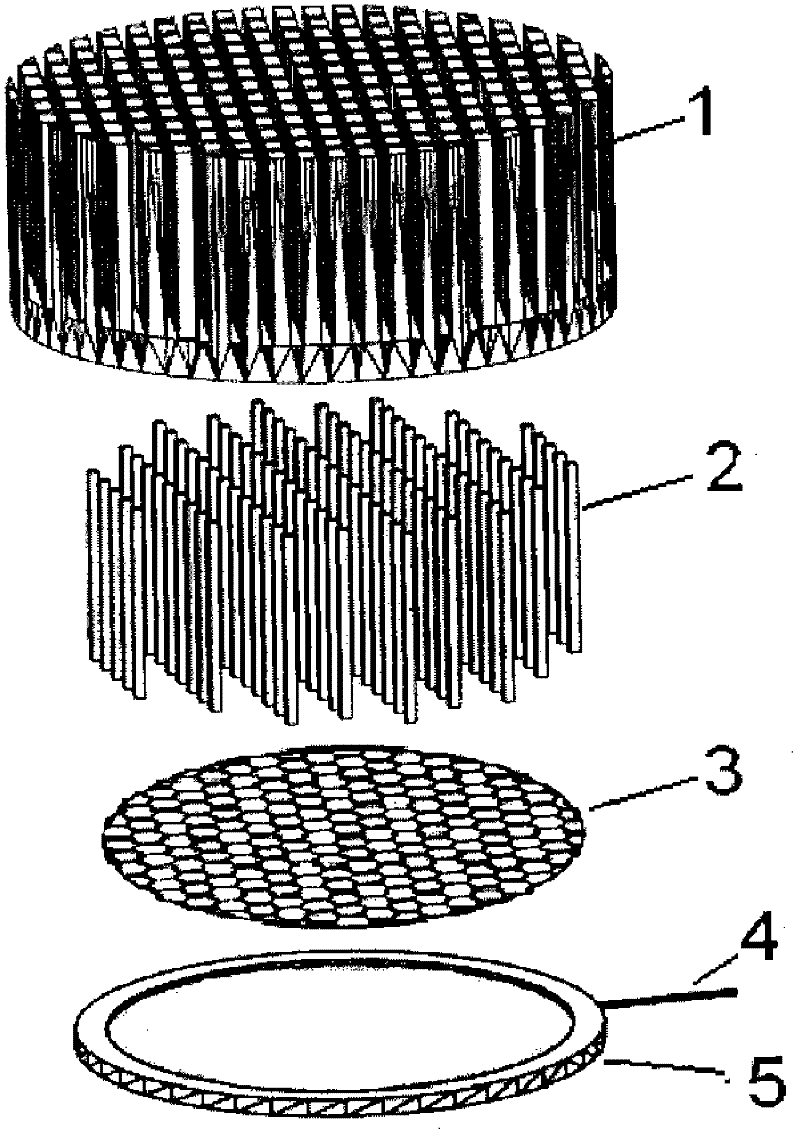

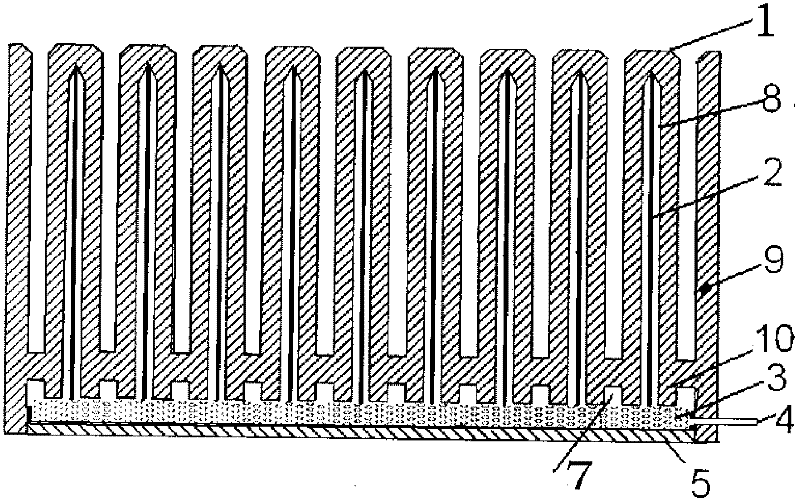

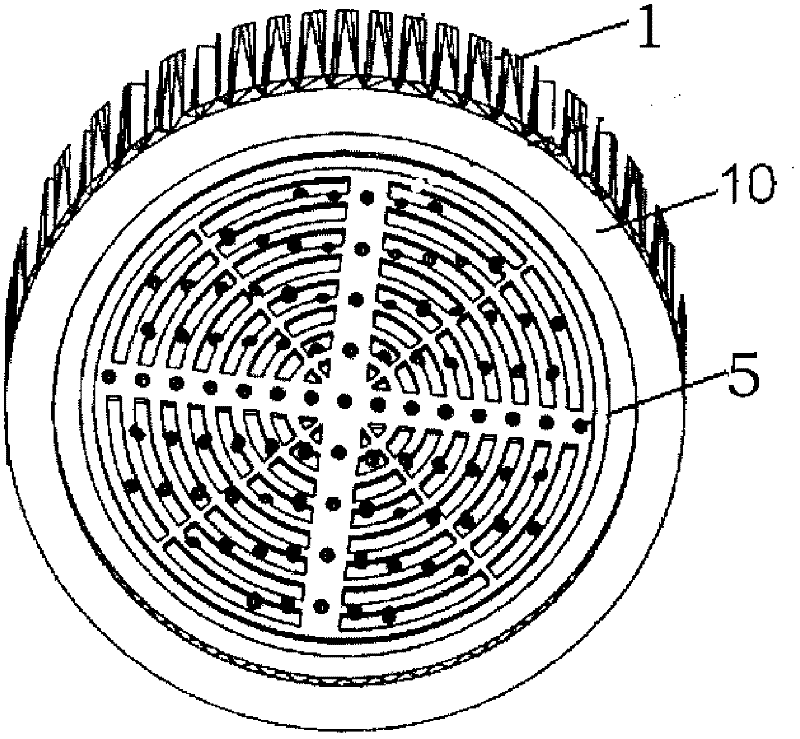

[0017] The invention provides an extended integrated flat heat pipe at the condensing end. Be described below in conjunction with accompanying drawing. figure 1 Shown is a schematic diagram of the assembly structure of the extended integrated flat heat pipe at the condensation end. figure 2 Shown is a schematic cross-sectional view of the integration of cooling fins and flat heat pipes. In the figure, the flat heat pipe includes the outer fins 9 of the heat dissipation fins 1 fixed to the bottom plate 5, that is, the bottom plate 5 of the flat heat pipe is packaged with the periphery of the bottom 10 of the heat dissipation fins. Porous metal material (porous materials such as copper foam, aluminum foam and nickel foam, etc., copper foam is the best) layer 3 is attached to the bottom plate 5 by sintering, and the gap between the middle fins of the cooling fins 1 and the middle The gaps between the fins and the outer fins 9 are equal and connected to each other at the heat d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com