Knitted fabric with unidirectional moisture conducting function and processing technology thereof

A knitted fabric, one-way moisture-wicking technology, applied in knitting, weft knitting, warp knitting, etc., can solve the problems of low processing efficiency, complex fabric processing technology, poor durability of one-way moisture-wicking function, etc., to improve processing efficiency, Guaranteed dryness and good hydrophilic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A kind of processing method of knitted fabric with unidirectional moisture-wicking function of the present invention: it comprises the following process steps:

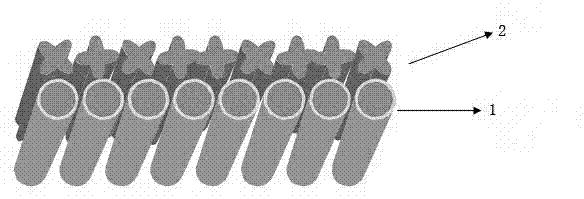

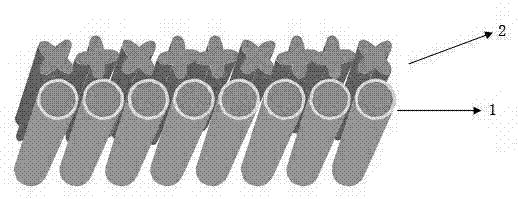

[0014] Firstly weaving the gray cloth, when weaving the gray cloth, the polypropylene fiber frame is fully or half opposite to ensure that the polypropylene fiber is always in the inner layer of the fabric;

[0015] Then carry out the pretreatment of the gray cloth, import the gray cloth into the L-type high-temperature and high-pressure overflow dyeing machine, add 2G / L soda ash and 2G / L oil-removing yarn agent at room temperature, raise the temperature to 110°C at 2.5°C / min and keep it for 20min, drain and overflow water wash;

[0016] Dyeing is carried out again, water is added, the temperature is raised to 50°C, 0.5 G / L glacial acetic acid is added, high-temperature and high-pressure leveling agent Suparex K powder is added: 1G / L, emulsifier: 0.5 G / L, Huntsman moisture-absorbing and quick-drying auxiliary a...

Embodiment 2

[0020] A kind of processing method of knitted fabric with unidirectional moisture-wicking function of the present invention: it comprises the following process steps:

[0021] Firstly weaving the gray cloth, when weaving the gray cloth, the polypropylene fiber frame is fully or half opposite to ensure that the polypropylene fiber is always in the inner layer of the fabric;

[0022] Then carry out the pretreatment of the gray cloth, import the gray cloth into the L-type high-temperature and high-pressure overflow dyeing machine, add 3G / L soda ash and 3G / L oil-removing yarn agent at room temperature, heat up at 1.75°C / min to 110°C for 20min, drain and overflow water wash;

[0023] Dyeing is carried out again, water is added, the temperature is raised to 50°C, 0.2 G / L glacial acetic acid is added, high-temperature and high-pressure leveling agent Suparex K powder: 0.5 G / L, emulsifier: 0.75G / L, Huntsman moisture-absorbing and quick-drying auxiliary HSD: 1G / L, after running for 10...

Embodiment 3

[0027]A kind of processing method of knitted fabric with unidirectional moisture-wicking function of the present invention: it comprises the following process steps:

[0028] Firstly weaving the gray cloth, when weaving the gray cloth, the polypropylene fiber frame is fully or half opposite to ensure that the polypropylene fiber is always in the inner layer of the fabric;

[0029] Then carry out the pretreatment of the gray cloth, import the gray cloth into the L-type high-temperature and high-pressure overflow dyeing machine, add 2.5 / L soda ash and 2.5G / L oil-removing yarn agent at room temperature, raise the temperature at 1°C / min to 110°C and keep it for 20 minutes, drain and overflow running water;

[0030] Dyeing is carried out again, water is added, the temperature is raised to 50°C, 0.35 G / L glacial acetic acid is added, high-temperature and high-pressure leveling agent Suparex K powder: 0.75G / L, emulsifier: 1G / L, Huntsman moisture-absorbing and quick-drying aid HSD : ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com