Method for extracting tea essential oil from oolong tea stalks

A technology for tea essential oil and oolong tea, which is applied in the field of extracting tea essential oil by using oolong tea stems, can solve the problems of low content of tea essential oil and high cost of extracting tea essential oil, and achieves the effects of less impurity content, avoiding water replenishment process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

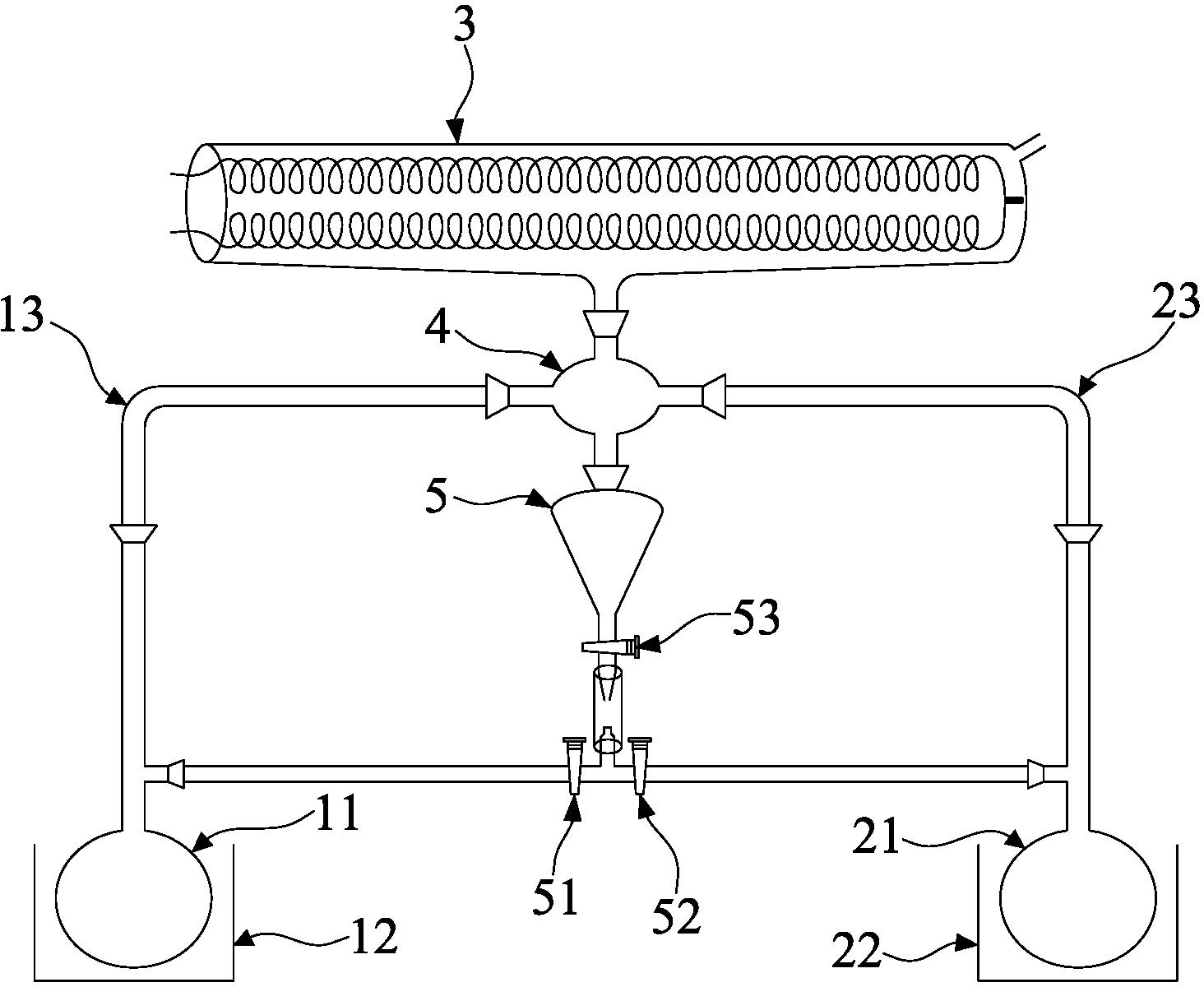

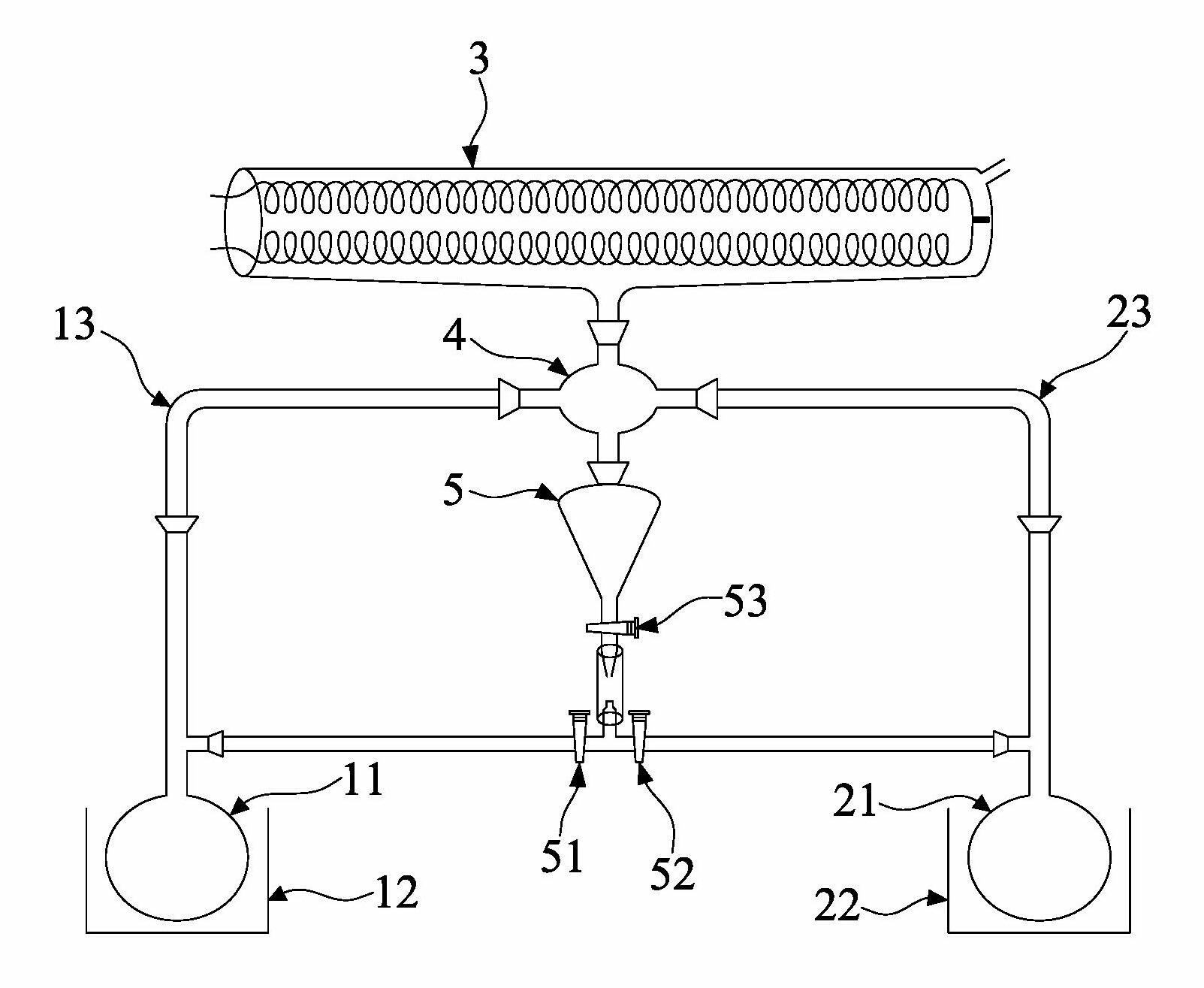

[0029] Weigh 40 g of pulverized tea stems into a 250 mL round bottom flask 11, add 160 mL of distilled water, and adjust the temperature of the electric heating mantle 12 to 95°C. At the same time, 120 mL of petroleum ether was placed in a 250 mL round bottom flask 21, and the temperature of the electric heating mantle 22 was adjusted to 40°C. After the tea steam in the round bottom flask 11 reaches the air storage bag 4 through the glass conduit 13, it is mixed with the petroleum ether vapor that reaches the air storage bag 4 through the glass conduit 23 in the round bottom flask 21, and enters the condensation pipe 3 to condense, and the condensate Backflow to the 150mL separatory funnel 5, open the main on-off valve 53 and the first reflux on-off valve 51 of the separatory funnel 5 every 12 minutes to reflux the lower layer aqueous solution into the flask 11, when the aqueous solution is exhausted, first close the total switch valve 53, and then close the first backflow swi...

Embodiment 2

[0031] Weigh 30 g of pulverized tea stems into a 250 mL round bottom flask 11, add 180 mL of distilled water, and adjust the temperature of the electric heating mantle 12 to 100°C. At the same time, 150 mL of petroleum ether was placed in a 250 mL round bottom flask 21, and the temperature of the electric heating mantle 22 was adjusted to 60°C. After the tea steam in the round bottom flask 11 reaches the air storage bag 4 through the glass conduit 13, it is mixed with the petroleum ether vapor that reaches the air storage bag 4 through the glass conduit 23 in the round bottom flask 21, and enters the condensation pipe 3 to condense, and the condensate Backflow to the 150mL separatory funnel 5, open the main switch valve 53 and the first reflux switch valve 51 of the separatory funnel 5 every 8 minutes to return the lower aqueous solution to the flask 11, when the aqueous solution is drained, first close the total switch valve 53, and then close the first backflow switch valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com