Environment-friendly flame-retardant adhesive for composite door coating

A composite door, flame retardant adhesive technology, applied in the directions of adhesives, adhesive types, adhesive additives, etc., can solve the problems of failing to meet the requirements of flame retardant and apparent quality of composite door veneers, and achieve the promotion of dehydrogenation reaction. And protect the carbon layer, improve the flame retardant efficiency, good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

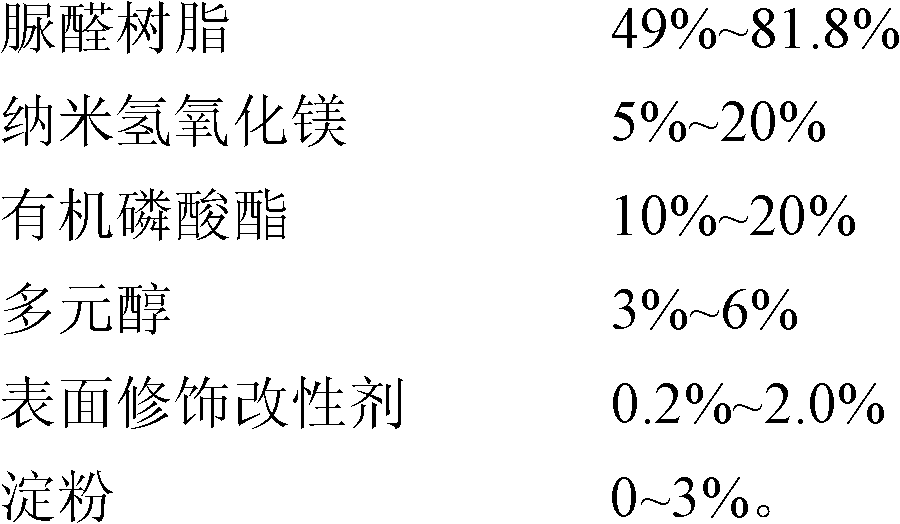

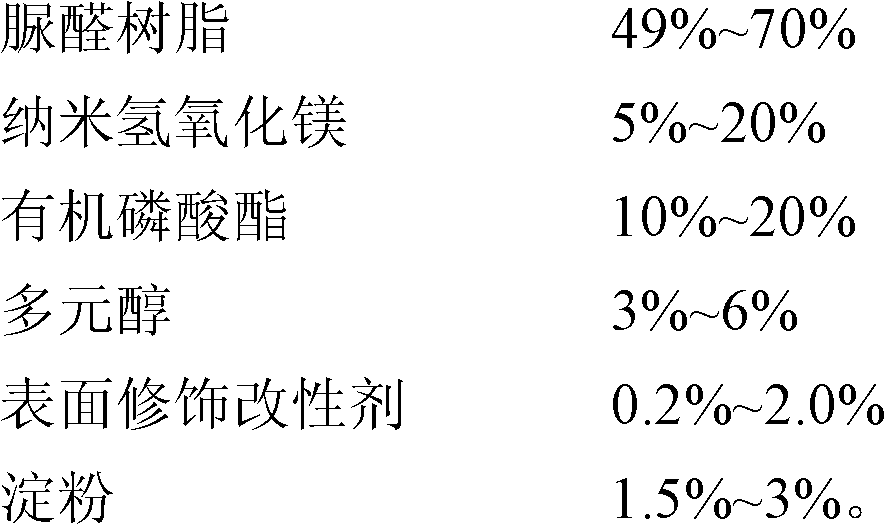

Method used

Image

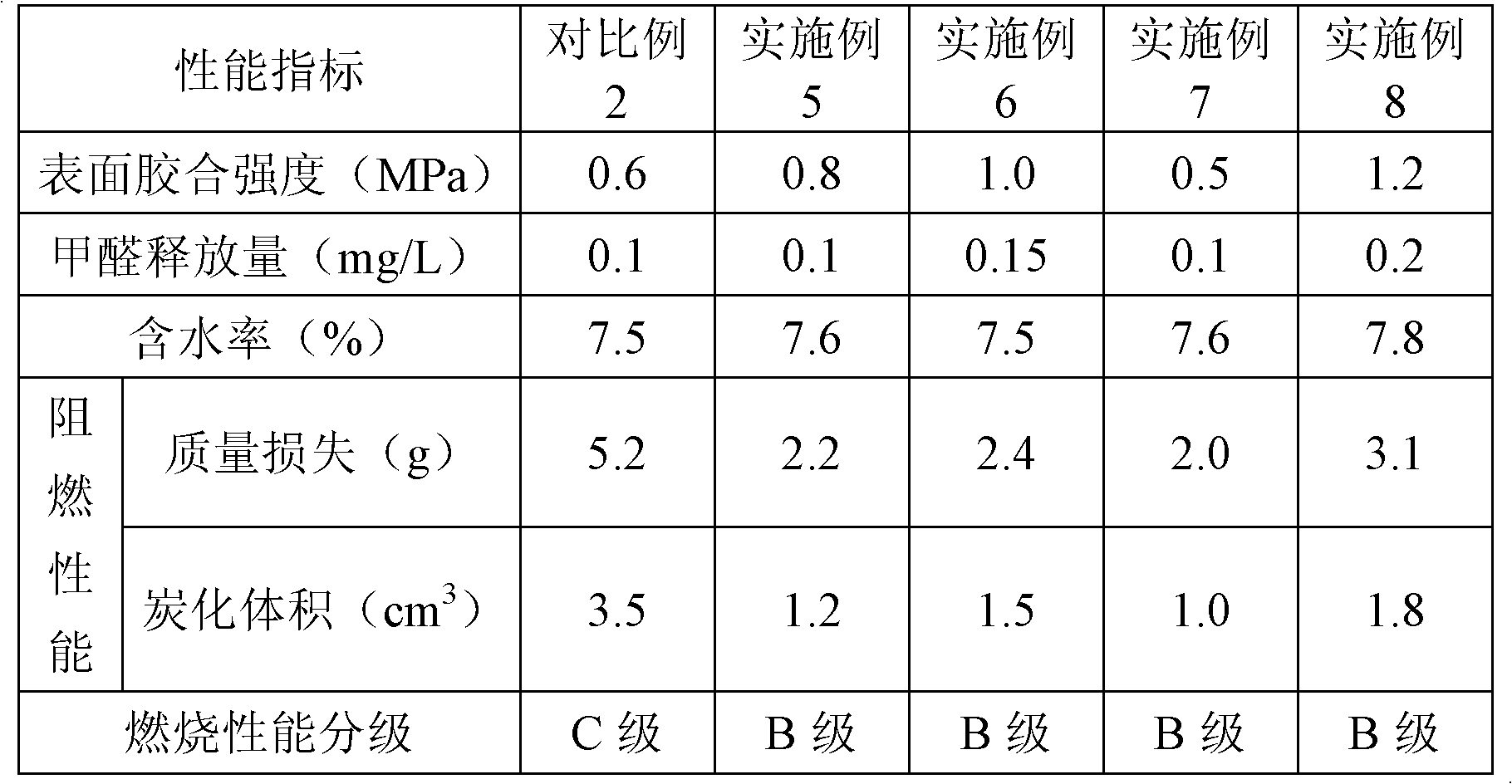

Examples

Embodiment 1

[0033] 15g of nano-magnesium hydroxide, 5g of pentaerythritol and 2g of starch are added to a high-speed (6000 rpm) mixer, and 1.2g of N-(β-aminoethyl)-γ-aminopropyltriethoxysilane is added, Mix at high speed for 30 minutes to make it evenly mixed, then add 17.5g resorcinol bis(di-o-methoxycarbonyl phenyl phosphate) and mix it for 10 minutes and then make it mix uniformly and discharge to obtain the compound; mix the compound with 59.3g The urea-formaldehyde resin is evenly ground to prepare an environmentally friendly flame-retardant adhesive for composite door veneers.

Embodiment 2

[0035] Add 10g of nano-magnesium hydroxide, 4g of pentaerythritol and 1.5g of starch into a high-speed (6000 rpm) mixer, add 0.8g of γ-aminopropyltrimethoxysilane, mix at high speed for 25 minutes to make it evenly mixed, and then add 15g resorcinol bis(m-di-tert-butylphenyl m-xylyl phosphate) was mixed for 10 minutes and then mixed uniformly and discharged to obtain a mixture; the mixture was uniformly ground with 68.7g urea-formaldehyde resin to obtain a composite door Environmental protection flame retardant adhesive for veneer.

Embodiment 3

[0037] Add 20g of nano-magnesium hydroxide, 6g of dipentaerythritol and 3g of starch into a high-speed (6000 rpm) mixer, add 2g of γ-aminopropyltriethoxysilane, mix at high speed for 30 minutes to make it evenly mixed, and then add 20g of bisphenol A bis(xylyl phosphate) was mixed for 10 minutes, then mixed uniformly and discharged to obtain a mixture; the mixture was evenly ground with 49g of urea-formaldehyde resin to obtain an environmentally friendly flame-retardant adhesive for composite door veneer .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com