Adhesive for cigar cigarettes and preparation method thereof

A technology of adhesives and cigars, applied in the direction of glucan adhesives, non-polymer adhesive additives, adhesive additives, etc. Suitable for application, high fluidity and other issues, to achieve the effect of improving appearance and internal quality, reducing the risk of mildew, and stabilizing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

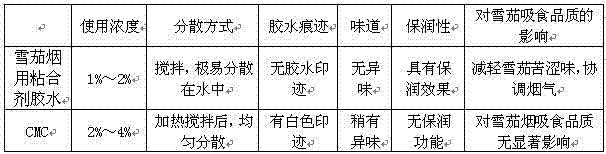

Image

Examples

Embodiment 1

[0042] (1) Prepare konjac fine powder with a particle size of 40 mesh by wet processing method;

[0043] (2) The konjac fine powder is purified 3 times with ethanol with a mass ratio concentration of 25%, each time for 90 minutes, and passed through a 120-mesh nylon screen filter to obtain a first-grade filter residue;

[0044] (3) Elute the primary filter residue with anhydrous ethanol of the same quality for 2 hours, and filter it with a 120-mesh nylon mesh filter to obtain the secondary filter residue;

[0045] (4) Vacuum-dry the secondary filter residue to remove black spots and ethanol odor, and obtain purified konjac fine powder;

[0046] (5) Grinding the purified konjac fine powder with a supersonic jet mill at a temperature of -5°C to obtain purified konjac fine powder with a fineness of 400 mesh and a moisture content of 7%±0.3%;

[0047] (6) Mix the purified konjac powder obtained in step (5) with water at a mass ratio of 1:50, and add 0.02% sorbic acid, 0.02% potas...

Embodiment 2

[0049] (1) Prepare konjac fine powder with a particle size of 80 mesh by dry processing method;

[0050] (2) The konjac fine powder is purified 3 times with ethanol with a mass ratio concentration of 45%, each time for 90 minutes, and passed through a 120-mesh nylon screen filter to obtain a first-grade filter residue;

[0051] (3) The primary filter residue was eluted with anhydrous ethanol 3 times its mass for 3 hours, and filtered with a 120-mesh nylon mesh filter to obtain the secondary filter residue;

[0052] (4) Vacuum-dry the secondary filter residue to remove black spots and ethanol odor, and obtain purified konjac fine powder;

[0053] (5) Grinding the purified konjac fine powder with a supersonic jet mill at a temperature of -5°C to obtain purified konjac fine powder with a fineness of 600 mesh and a moisture content of 7%±0.3%;

[0054] (6) Mix the purified konjac powder obtained in step (5) with water at a mass ratio of 1:100, and add 0.05% potassium sorbate, 0.0...

Embodiment 3

[0056] (1) Prepare konjac fine powder with a particle size of 60 mesh by wet processing method;

[0057] (2) The konjac fine powder is purified 3 times with ethanol with a mass ratio concentration of 35%, each time for 90 minutes, and passed through a 120-mesh nylon screen filter to obtain a first-grade filter residue;

[0058] (3) The primary filter residue was eluted with anhydrous ethanol twice its mass for 3 hours, and filtered with a 120-mesh nylon mesh filter to obtain the secondary filter residue;

[0059](4) Vacuum-dry the secondary filter residue to remove black spots and ethanol odor, and obtain purified konjac fine powder;

[0060] (5) Grinding the purified konjac fine powder with a supersonic jet mill at a temperature of -5°C to obtain purified konjac fine powder with a fineness of 200 mesh and a moisture content of 7%±0.3%;

[0061] (6) Mix the purified konjac powder obtained in step (5) with water at a mass ratio of 1:150, and add 0.03% potassium sorbate, 0.04% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com