Polyurethane modified unsaturated polyester resin composition and preparation method thereof

A technology of polyurethane modification and polyester resin, applied in the field of polyurethane modified unsaturated polyester resin composition and preparation thereof, can solve the problems of unsatisfactory impact performance, poor impact resistance, easy cracking, etc., and achieves improvement and The effect of increasing comprehensive properties, high adhesion, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

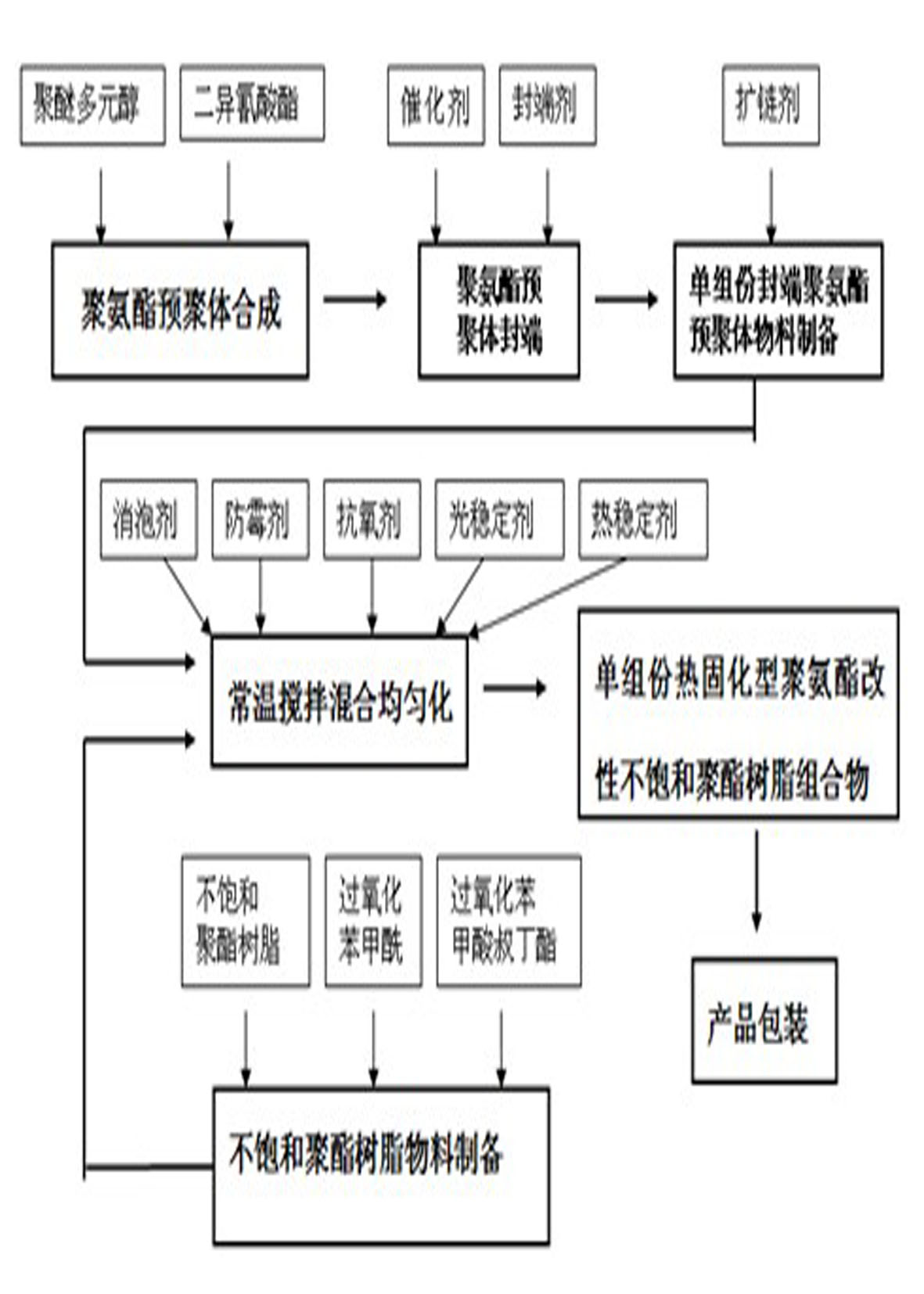

[0038] Implement the preparation method of a kind of polyurethane modified unsaturated polyester resin composition described in the present invention, the feeding amount is all calculated by mass fraction, preparation process conditions and process are shown in the attached figure 1 :

[0039] 1. Preparation of one-component end-capped polyurethane prepolymer

[0040] ① Synthesis of polyurethane prepolymer

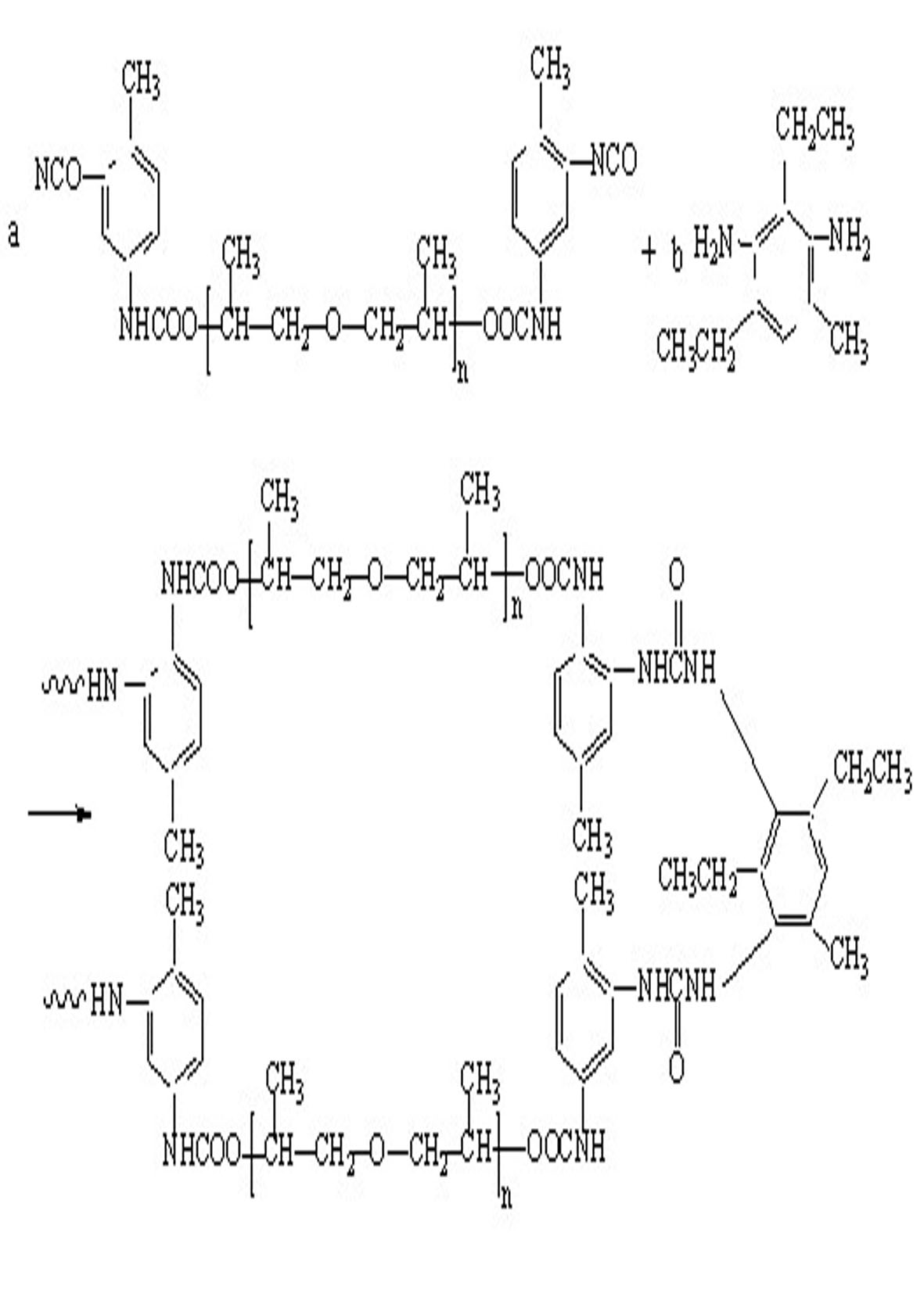

[0041] Add 100 parts of polyether polyol N210 and 100 parts of polyether polyol N220 into the reactor according to the mass fraction, heat up to 125-135°C, keep stirring, keep the vacuum at 0.08-0.09 Mpa, and vacuum dehydrate for 2 hours , placed to lower the temperature to about 40°C, then add 64 parts of toluene diisocyanate (TDI-80), raise the temperature to 80±2°C and keep it warm for 2.5 hours to prepare a polyurethane preform with a free isocyanate group-NCO content of 7%. Polymer. The reaction scheme is as follows:

[0042]

[0043] ② End capping of polyureth...

specific Embodiment approach 2

[0052] (The dosages mentioned below are all mass fractions)

[0053] 1. Preparation of one-component end-capped polyurethane prepolymer

[0054] ①Synthesis of polyurethane prepolymer

[0055] Add 100 parts of polyether polyol N210 and 100 parts of polyether polyol N220 into the reactor according to the mass fraction, heat up to 125-135°C, keep stirring, keep the vacuum at 0.08 Mpa, vacuumize and dehydrate for 2 hours, and place Lower the temperature to about 40°C, then add 85 parts of toluene diisocyanate (TDI-80), raise the temperature to 80°C and keep it warm for 2.5 hours to prepare a polyurethane prepolymer with a free-NCO content of 10%. The reaction scheme is as follows:

[0056]

[0057] ②Encapping of polyurethane prepolymer

[0058] Add organic composite metal catalyst BiCAT to step ① reactor ? 1.2 parts of 3484 (M) catalyst, stir and heat up to 80°C, then take 62 parts of end-capping agent methyl ethyl ketone oxime, and add it dropwise to the above polyurethane...

specific Embodiment approach 3

[0067] (The dosages mentioned below are all mass fractions)

[0068] 1. Preparation of one-component end-capped polyurethane prepolymer

[0069] ①Synthesis of polyurethane prepolymer

[0070] Add 100 parts of polyether polyol N210 and 100 parts of polyether polyol N220 into the reactor by mass, heat up to 125-135°C, keep stirring, keep the vacuum at 0.08 Mpa, vacuumize and dehydrate for 2 hours, and let it stand for The temperature is lowered to about 40°C, and then 78 parts of toluene diisocyanate (TDI-80) is added, and the temperature is raised to 80°C for 2.5 hours, and the polyurethane prepolymer with a free-NCO content of 9% is obtained. The reaction scheme is as follows:

[0071]

[0072] ②Encapping of polyurethane prepolymer

[0073] Add organic composite metal catalyst BiCAT to step ① reactor ? 1.5 parts of 3484 (M) catalyst, stir and heat up to 80°C, then take 59 parts of ethylene glycol monoethyl ether as an end-capping agent, and add it dropwise to the above-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com