Permissible emulsion explosive for tertiary coal mine and its preparation method

A technology of emulsified explosives and coal mines, which is applied in the direction of explosives, etc., can solve the problems of high cost of raw materials, achieve the effects of simple production process, small flame, and reduce the amount of online storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

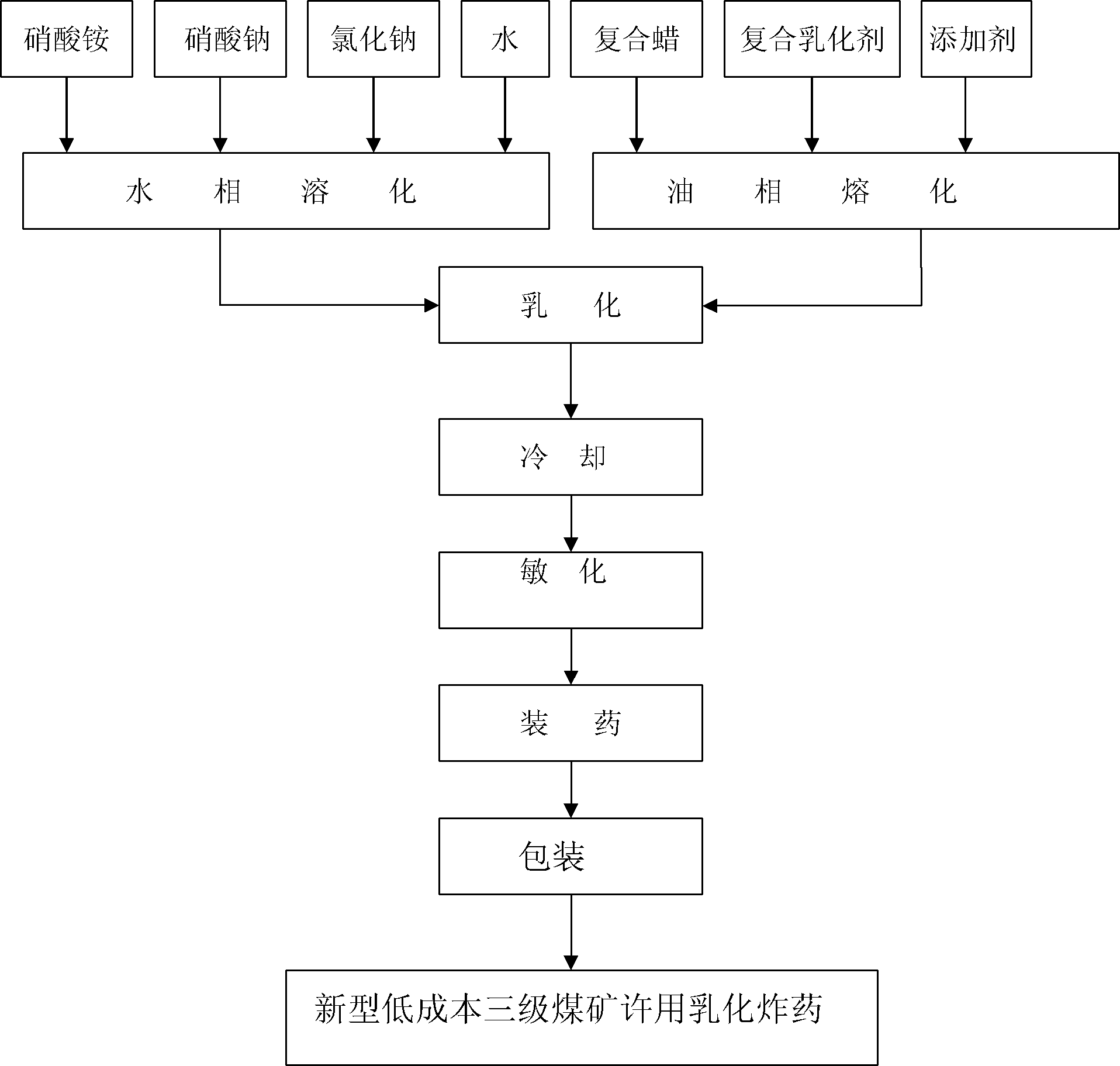

Method used

Image

Examples

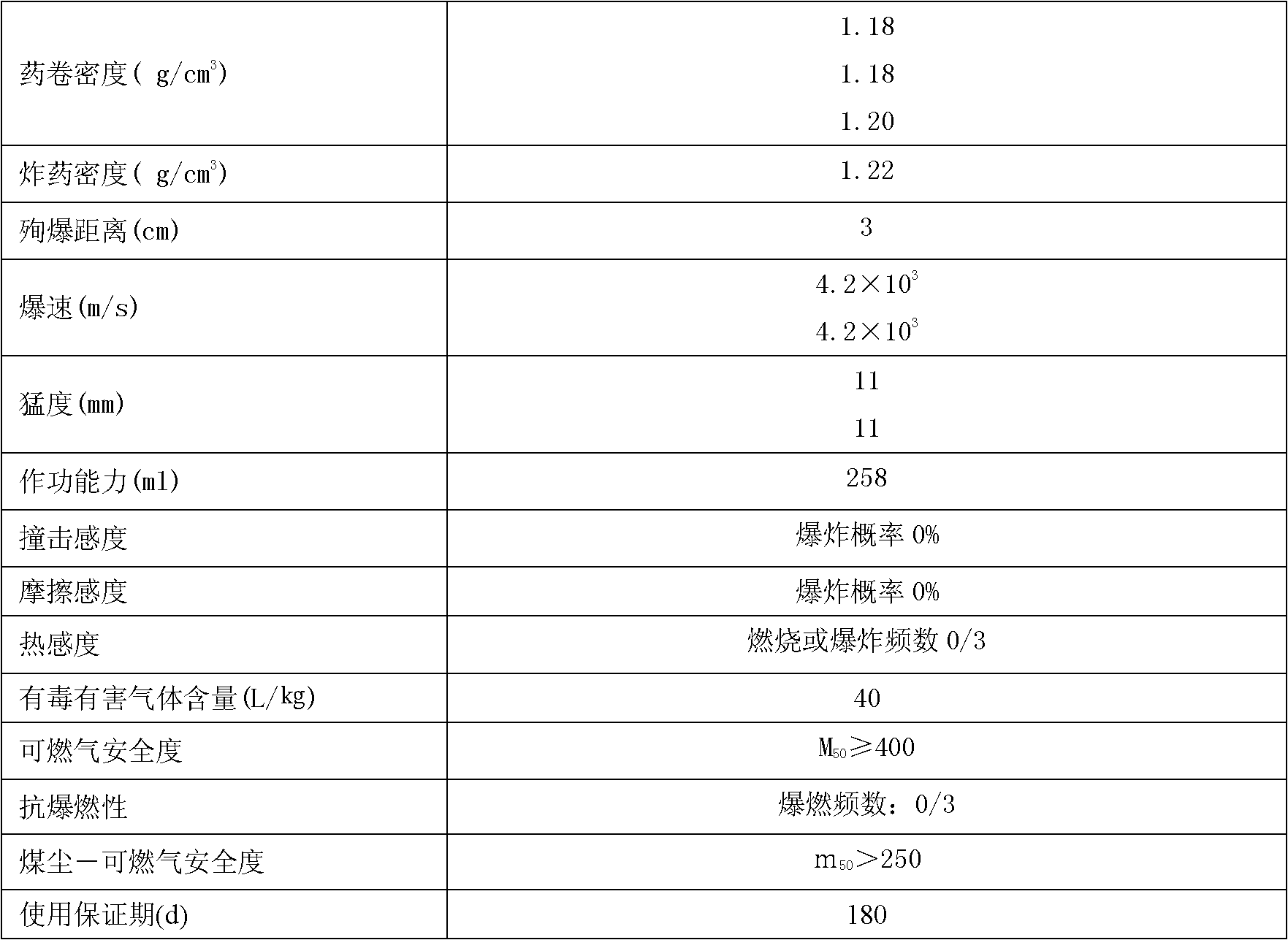

Embodiment 1

[0028] Raw materials are prepared according to the following weight percentages, namely: 66.5 parts of ammonium nitrate, 6.5 parts of sodium nitrate, 12 parts of sodium chloride, 9 parts of water, 2.5 parts of composite emulsifier, 3.0 parts of composite wax, 0.5 part of additive, wherein the composite wax is paraffin wax and The mixture of petrolatum, the weight ratio is 1:1, the additive is fatty alcohol, the production process operation steps:

[0029] (1) heating the mixture composed of ammonium nitrate, sodium chloride, sodium nitrate and water to 110°C to 130°C to dissolve to form an oxidizing agent solution, and filter;

[0030] (2) Heat the mixture composed of compound emulsifier, compound wax and additives to 90°C to 100°C to melt to form a combustible solution and filter;

[0031] (3) Use a metering pump to pump the oxidant water phase solution and the combustible oil phase solution into the static mixer for mixing, and then transport them into the first-stage emulsi...

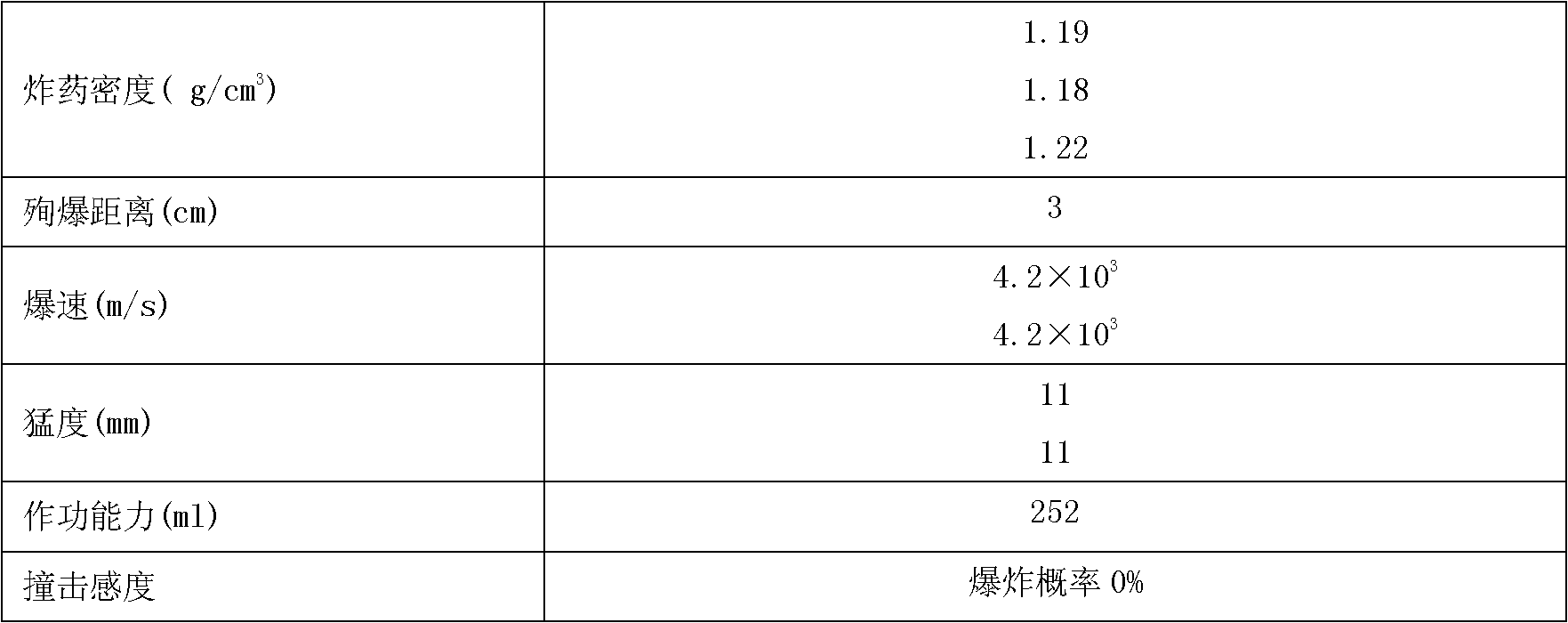

Embodiment 2

[0038] Raw materials are prepared according to the following weight percentages, namely: 69 parts of ammonium nitrate, 7 parts of sodium nitrate, 8 parts of sodium chloride, 10 parts of water, 2.3 parts of composite emulsifier, 3.0 parts of composite wax, 0.7 part of additive, wherein composite wax is paraffin wax and The mixture of petrolatum, the weight ratio is 1:1, and the additive is fatty alcohol. Production process operation steps:

[0039] (1) heating the mixture composed of ammonium nitrate, sodium chloride, sodium nitrate and water to 110°C to 130°C to dissolve to form an oxidizing agent solution, and filter;

[0040] (2) Heat the mixture composed of compound emulsifier, compound wax and additives to 90°C to 100°C to melt to form a combustible solution and filter;

[0041] (3) Use a metering pump to pump the oxidant water phase solution and the combustible oil phase solution into the static mixer for mixing, and then transport them into the first-stage emulsifier fo...

Embodiment 3

[0049] Raw materials are prepared according to the following weight percentages, namely: 71 parts of ammonium nitrate, 5 parts of sodium nitrate, 8 parts of sodium chloride, 10 parts of water, 2.4 parts of composite emulsifier, 2.8 parts of composite wax, 0.8 part of additive, wherein composite wax is paraffin wax and The mixture of petrolatum, the weight ratio is 1:1, the additive is fatty alcohol, the production process operation steps:

[0050] (1) heating the mixture composed of ammonium nitrate, sodium chloride, sodium nitrate and water to 110°C to 130°C to dissolve to form an oxidizing agent solution, and filter;

[0051] (2) Heat the mixture composed of compound emulsifier, compound wax and additives to 90°C to 100°C to melt to form a combustible solution and filter;

[0052] (3) Use a metering pump to pump the oxidant water phase solution and the combustible oil phase solution into the static mixer for mixing, and then transport them into the first-stage emulsifier for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com