Up-conversion luminescence transparent glass ceramics and preparation method thereof

A transparent glass and ceramic technology, applied in the field of preparation of up-conversion luminescent transparent glass ceramics, can solve the problems of precise control of composition, insufficient doping uniformity, uncontrollable enrichment of doping ions, etc., and achieve low production cost, high fluorescence The effect of strong strength and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

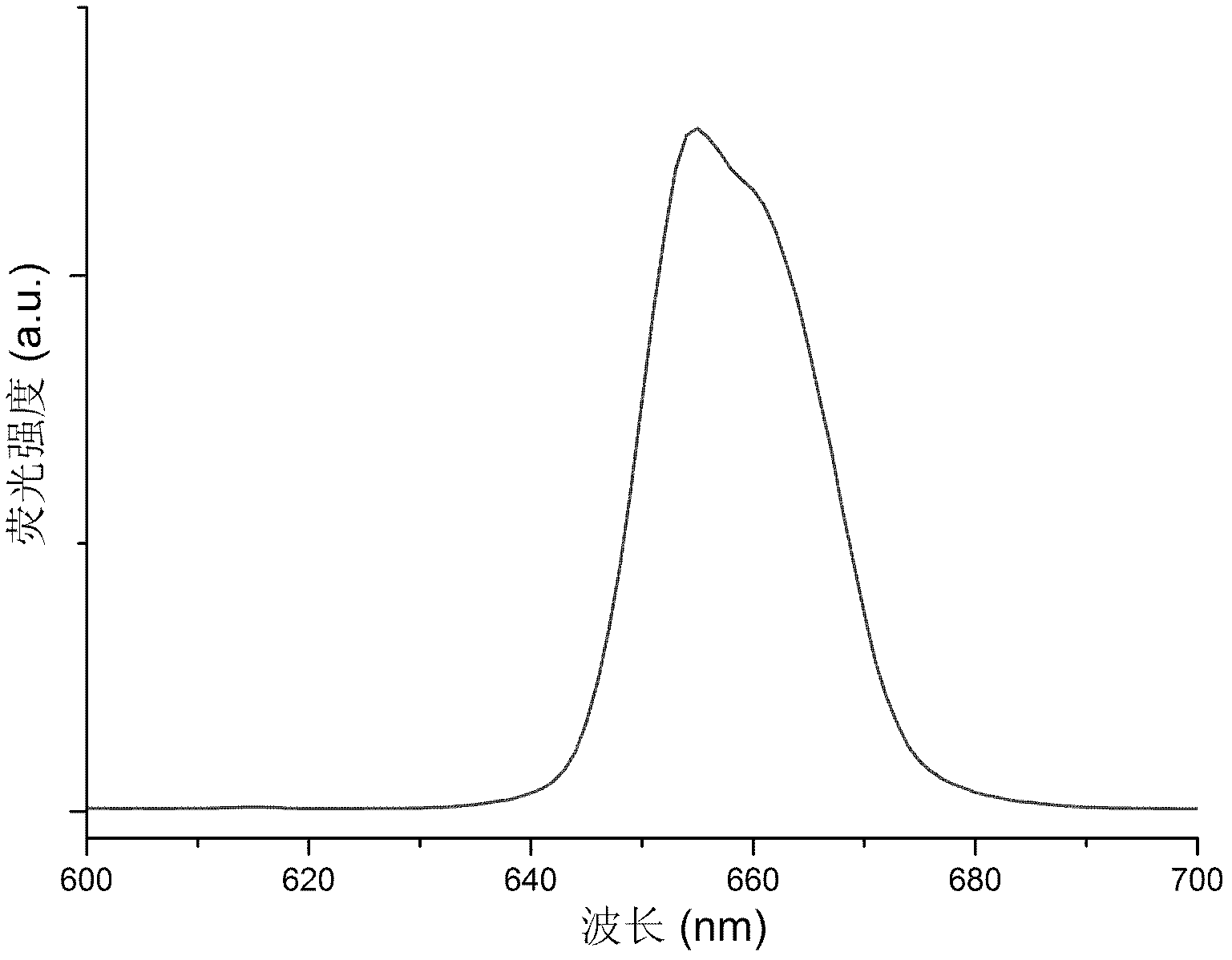

example 1

[0012] Example 1: Analytical pure Al 2 o 3 、Na 2 CO 3 、H 3 BO 3 and prepared Gd 2 o 3 Nanocrystalline, by Al 2 o 3 :Na 2 CO 3 :H 3 BO 3 :Gd 2 o 3 = 4:4:20:1 (molar ratio) The ratio is accurately weighed and mixed, fully ground in an agate mortar to form a uniform powder, then placed in a platinum crucible, and heated to 1100°C in a programmable resistance furnace And keep it warm for 3 hours, then pour the molten liquid into a preheated copper mold to form; the obtained glass ceramics are put into a programmable resistance furnace and heated to 600°C and kept warm for 3 hours, and then you can get gadolinium oxide-doped transparent glass ceramics , the sample has been surface polished, and the red light upconversion luminescence signal can be observed by Horiba JY FL3 fluorescence spectrometer. The accompanying drawing is the fluorescence emission curve of the prepared glass ceramics, which shows that it is red up-conversion luminescence.

example 2

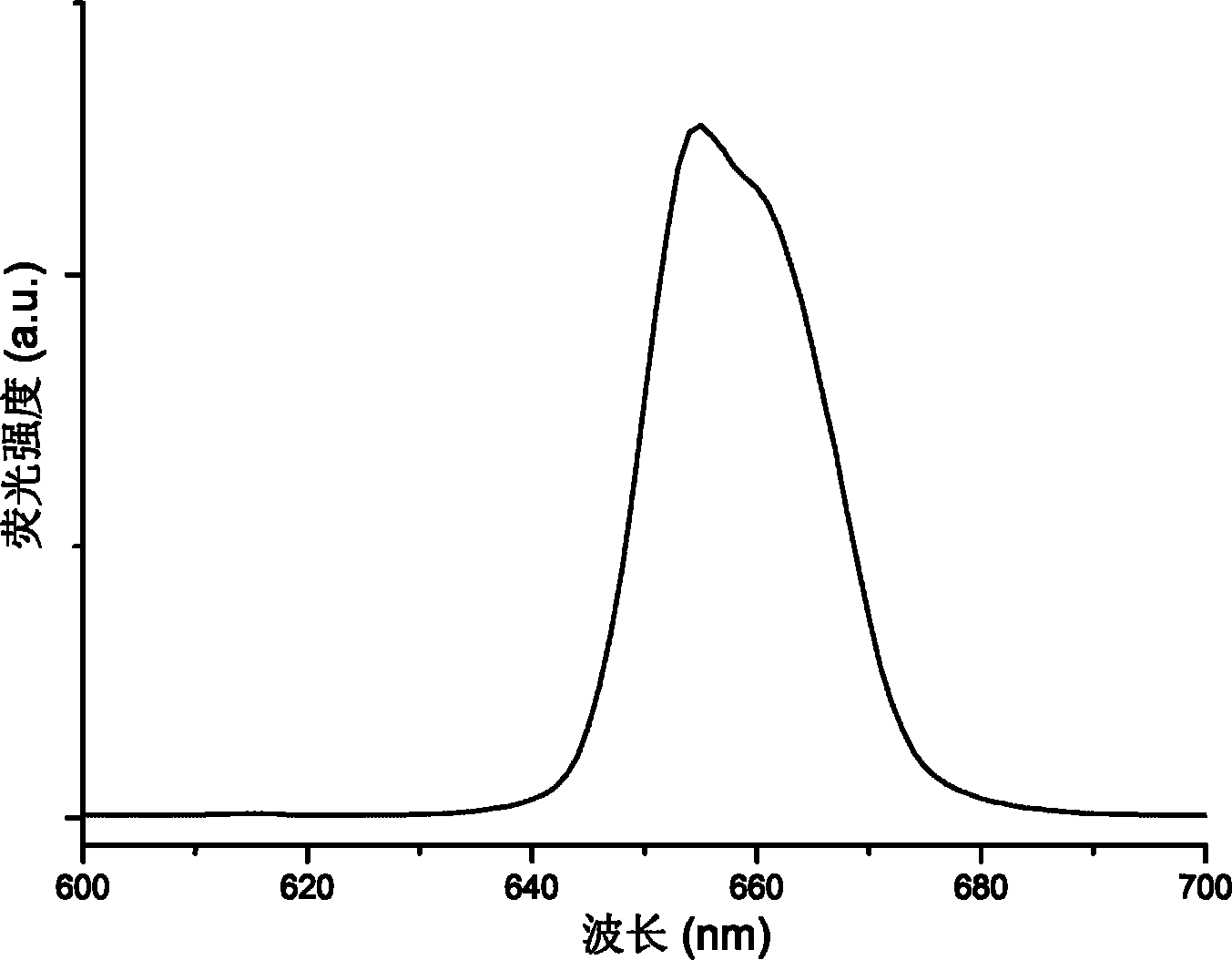

[0013] Example 2: Analytical pure Al 2 o 3 、Na 2 CO 3 、H 3 BO 3 and prepared Gd 2 o 3 Nanocrystalline, by Al 2 o 3 :Na 2 CO 3 :H 3 BO 3 :Gd 2 o 3 = 4:4:30:1 (molar ratio) The ratio is accurately weighed and mixed, fully ground in an agate mortar to form a mixed uniform powder, then placed in a platinum crucible, and heated to 1000 ° C in a programmable resistance furnace And keep it warm for 3 hours, then pour the molten liquid into a preheated copper mold to form; the obtained glass ceramics are put into a programmable resistance furnace and heated to 600°C and kept warm for 3 hours, and then you can get gadolinium oxide-doped transparent glass ceramics , the sample has been surface polished, and the up-converted red light signal can be observed when measured with a Horiba JY FL3 fluorescence spectrometer.

example 3

[0014] Example 3: Analytical pure Al 2 o 3 、Na 2 CO 3 、H 3 BO 3 and prepared Gd 2 o 3 Nanocrystalline, by Al 2 o 3 :Na 2 CO 3 :H 3 BO 3 :Gd 2 o 3 = 4:8:20:1 (molar ratio) The ratio is accurately weighed and mixed, fully ground in an agate mortar to form a uniform powder, then placed in a platinum crucible, and heated to 1200 ° C in a programmable resistance furnace And keep it warm for 3 hours, then pour the molten liquid into a preheated copper mold to form; the obtained glass ceramics are put into a programmable resistance furnace and heated to 600°C and kept warm for 3 hours, and then you can get gadolinium oxide-doped transparent glass ceramics , the sample has been surface polished, and the up-converted red light signal can be observed when measured with a Horiba JY FL3 fluorescence spectrometer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com