Method for preparing grapheme through oxidation reduction

A graphene and graphite technology, which is applied in the field of redox preparation of graphene, can solve the problems of serious agglomeration, less good reduction effect than hydrazine hydrate, limited promotion and application of toxicity, and achieves low production cost, safe preparation method, and environmental friendliness. Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Preparation of graphite oxide:

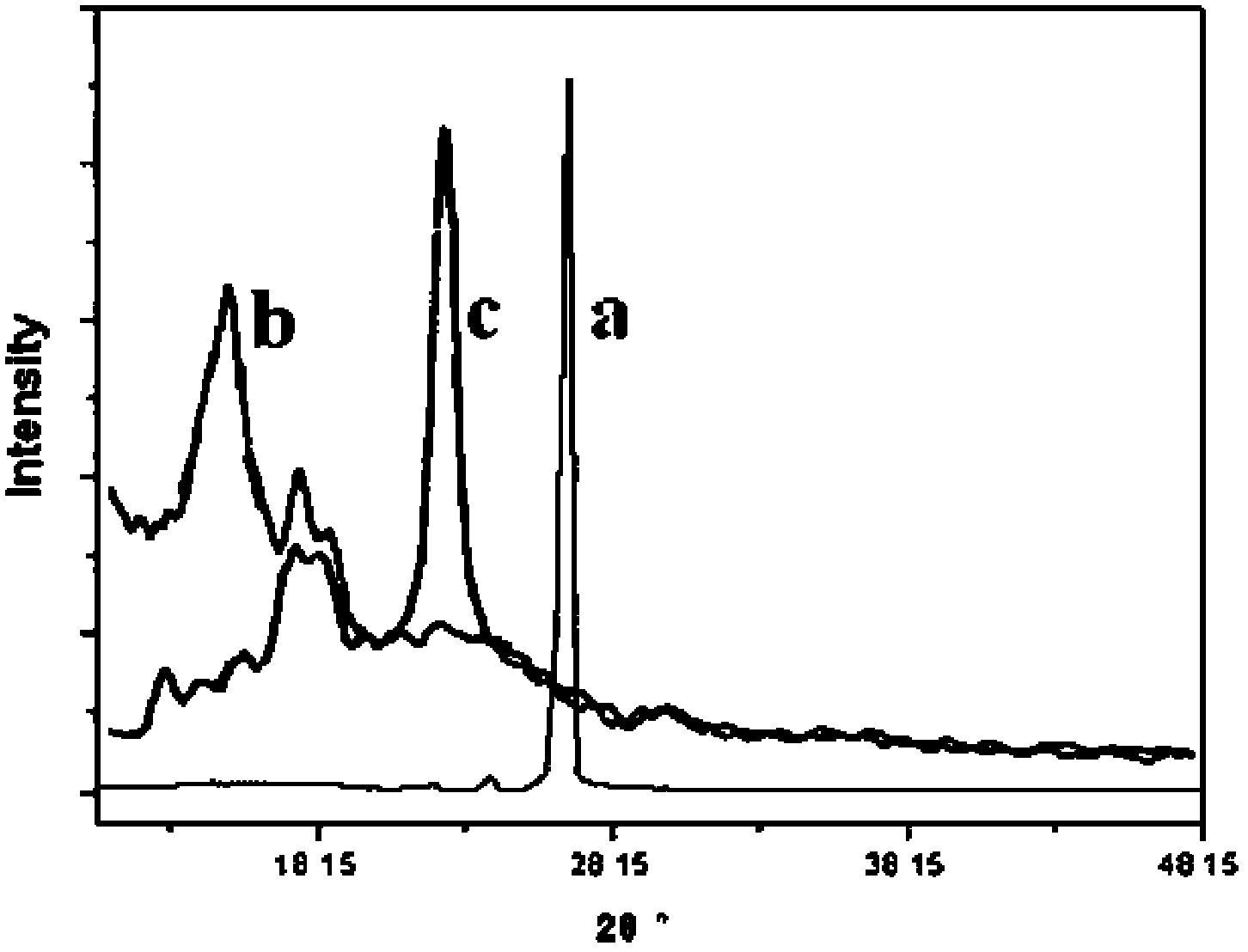

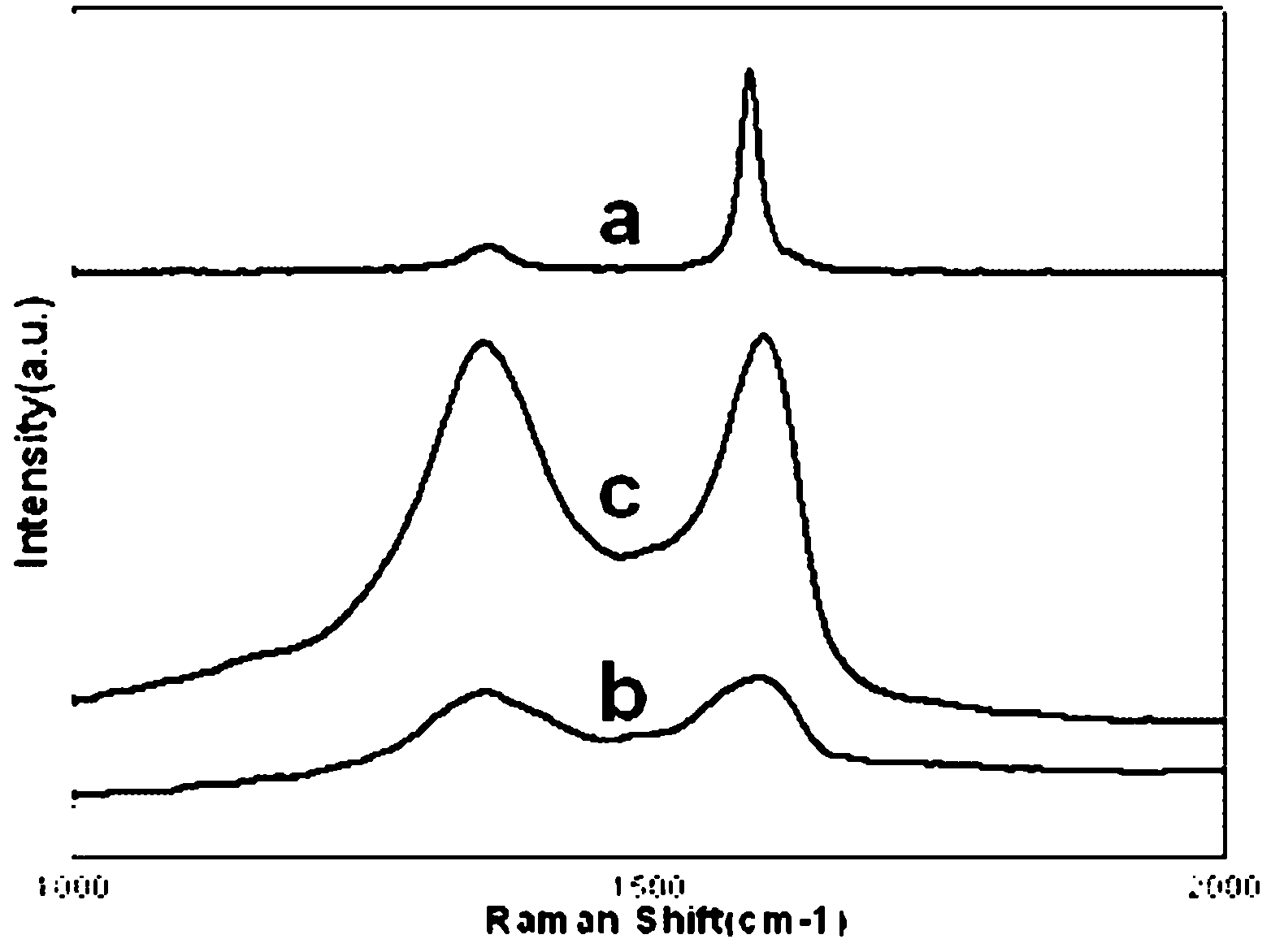

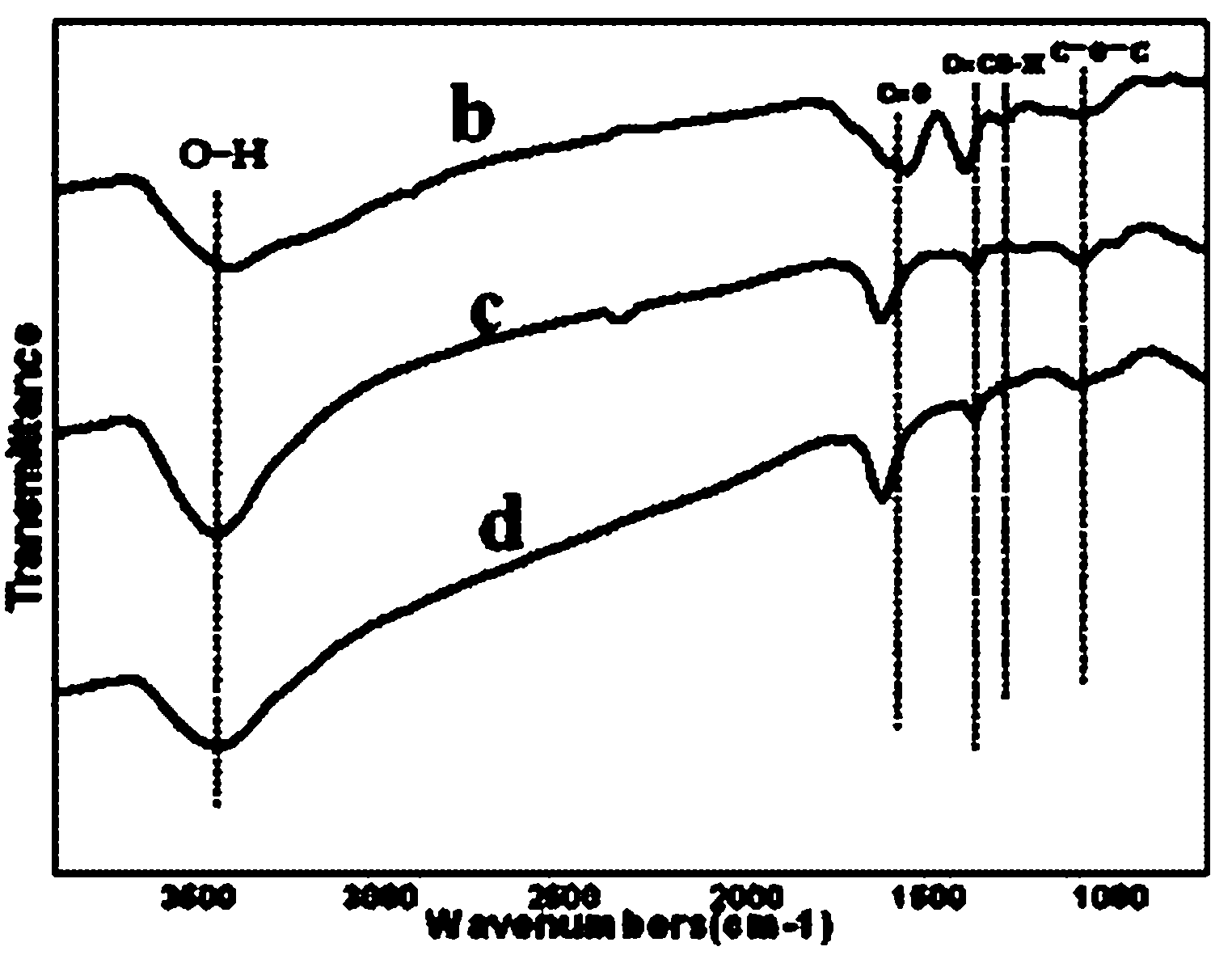

[0028] Get 1g (83 mesh) natural flake graphite and 50ml mass concentration is 98% sulfuric acid after mixing evenly, add 1.0g potassium nitrate, add 6g potassium permanganate rapidly in the water bath of 15 ℃, mix well, add the potassium permanganate The process maintains the system temperature at 0-20°C. Then the temperature of the system was raised to 40°C, reacted for 3h, then added 30ml of water, and simultaneously raised the temperature of the system to 80°C for 30min, then reduced the excess potassium permanganate with 50ml of distilled water and 10ml of hydrogen peroxide (30wt%), and centrifugally washed to The pH was 5, and the graphite oxide solid was obtained by vacuum drying at 40°C. XRD characterization as figure 1 As shown in curve b, the interlayer distance of graphite oxide can be obtained to be 0.863nm, which is greatly increased compared with the interlayer distance of 0.34nm of initial graphite (a), indicating that...

Embodiment 2

[0034] 1) Preparation of graphite oxide:

[0035] Get 1g (83 mesh) natural flake graphite and 45ml mass concentration is 98% sulfuric acid after mixing uniformly, add 1.2g potassium nitrate, add 3g potassium permanganate rapidly in the water bath of 10 ℃, mix uniformly, add potassium permanganate The process maintains the system temperature at 0-20°C. Then the temperature of the system was raised to 50° C., reacted for 2 hours, then added 50 ml of water, and the system was heated to 90° C. for 20 minutes, and then the excess potassium permanganate was reduced with 100 ml of distilled water and 6 ml of hydrogen peroxide (30 wt %), and centrifugally washed to The pH was 6, and the graphite oxide solid was obtained by vacuum drying at 60°C. Similar to the characterization results of Example 1, the interlayer distance obtained by XRD analysis is 0.853 nm, which indicates that the graphite oxide has a good oxidation effect.

[0036] 2) Preparation of graphene oxide suspension:

...

Embodiment 3

[0041] 1) Preparation of graphite oxide:

[0042] Take 1g (16 mesh) of natural flake graphite and 40ml of mass concentration of 98% sulfuric acid and mix evenly, add 1.5g of potassium nitrate, quickly add 6g of potassium perchlorate in a water bath at 5°C, mix well, and maintain the temperature of the system during the process of adding potassium perchlorate 0-20°C. Then raise the temperature of the system to 60°C, react for 1.5h, then add 80ml of water, and at the same time raise the temperature of the system to 95°C for 10min, then add 200ml of distilled water to terminate the reaction, centrifugally wash until the pH is 7, and vacuum dry at 70°C to obtain graphite oxide solid. Consistent with the characterization results of Example 1, the interlayer distance of graphite oxide is 0.835nm, which is significantly increased compared with the initial graphite, indicating that the oxidation effect of graphite oxide is very good.

[0043] 2) Preparation of graphene oxide suspens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com