Method for light alloy welding and multi-pass system

A light alloy, multi-light path technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of irregular weld seam and low absorption rate, so as to increase the melting width, increase the absorption rate, and expand the application space wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following takes a high-power Nd:YAG solid-state laser (which can be used for welding light alloys, such as aluminum alloy sheet welding) as an example to further illustrate the specific implementation of the present invention, but the scope of protection of the present invention is not limited to the following examples.

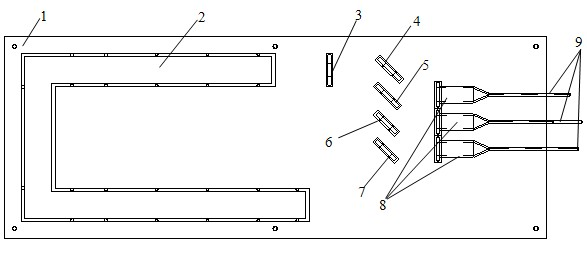

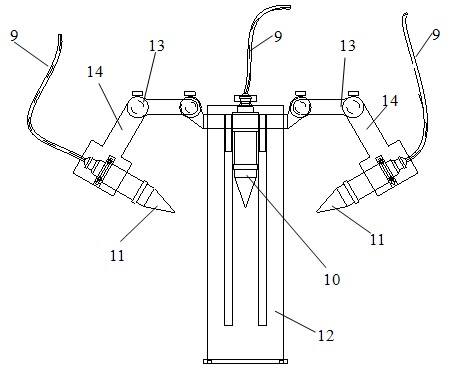

[0022] exist figure 1 Medium and high power Nd: YAG pulsed solid-state laser 2, laser output mirror 3 are installed on the light focusing seat 1, 45° total reflection mirror 4 is installed on the light emitted by the laser output mirror 3, the main optical path is 45° half mirror 5 , Auxiliary optical path 45 ° half mirror 6, auxiliary optical path 45 ° full reflective mirror 7 are parallel with 45 ° full reflective mirror 4 and are installed on the outgoing light of 45 ° full reflective mirror 4 at intervals. Three fiber optic coupling mirrors 8 are respectively installed at intervals on the reflection light of the main optical path 45 ° half mirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com