Welding method of target and back plate

A welding method and target technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of large waste of backing materials, affecting the quality of the film layer, hindering diffusion welding, etc. The effect of simplifying process steps and saving process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

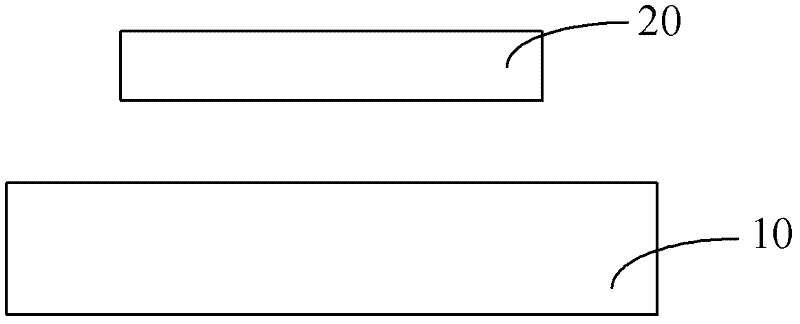

[0034] Semiconductor integrated circuits usually use titanium targets for physical vapor deposition (PVD, Physical Vapor Deposition) to coat films. Titanium targets usually use magnetron sputtering in the sputtering process. The high aluminum alloy material is used as the back plate, which is welded together with the titanium target to be installed on the sputtering machine table, and is used for the sputtering target assembly in the semiconductor process.

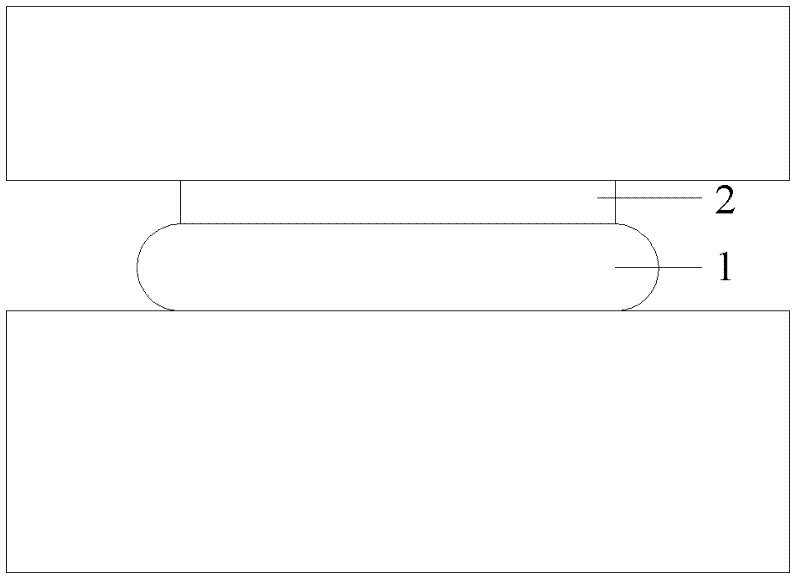

[0035] See figure 1 , figure 1 It is a schematic diagram of welding titanium target and aluminum back plate by HP method. The inventor found that during the welding process of titanium target material 2 and aluminum back plate 1, the aluminum material will move along the aluminum back plate during the hot pressing process of aluminum back plate 1. Outer bulge, such as figure 1 The arc part of the shown aluminum backplane 1 leads to waste of aluminum backplane material, and the thickness of the finally obtained aluminum b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com