Wheat flour milling wheat treating workshop process only stripping pericarp and complete equipment

A complete set of equipment and wheat technology, applied in the direction of grain degermination, grain processing, grain milling, etc., can solve the problems of high energy consumption, affecting production by moistening the wheat silo, and the ash content of the output flour is not obvious, and achieves economic and social benefits. Huge benefits, avoid water pollution, reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described in detail below with reference to the embodiments, but the protection scope of the present invention is not limited thereto.

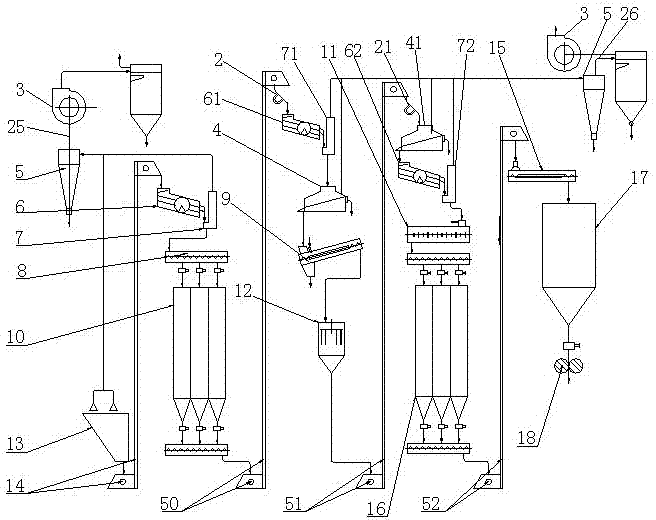

[0025] A kind of wheat flour milling process that only peels off the peel. The process flow includes the cleaning (screening, winnowing, magnetic separation, second screening and second winnowing), peeling (watering and stirring), light wheat Cleaning (magnetic separation, stone removal, screening and winnowing) and tempering treatment (watering and moistening).

[0026] The specific steps of the peeling section are as follows: add water about 3% of the weight of the wheat to the wheat, and the water temperature is about 35°C. After the water is added, it is sent to the mixing process for processing within 10 minutes, and the height of the wheat is controlled at 0.5-3m during the mixing process. , When mixing, use a mixer to control the linear speed of the mixer's stirring rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com