Iron, nitrogen and fluoride co-doped titanium dioxide (TiO2) photocatalyst and application thereof in degrading organic pollutants in visible light

A technology of organic pollutants and photocatalysts, applied in water pollutants, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low solar energy utilization, low quantum yield, etc. Good photocatalytic performance and inhibition of recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

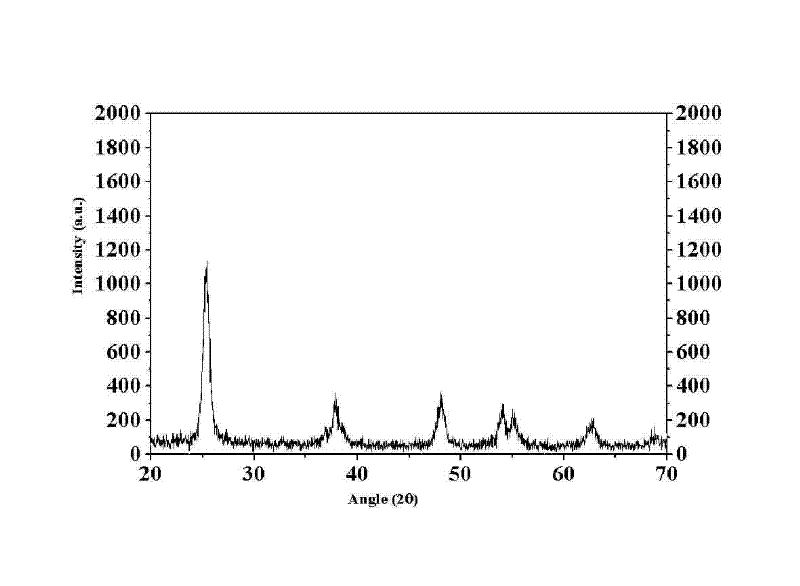

[0023] Example 1 Iron Nitrogen Fluoride Co-doped TiO 2 catalyst of light

[0024] (1) Preparation method

[0025] Under rapid stirring, 10 mL (0.03 mol) of butyl titanate was slowly dropped into a mixed solution of 30 mL of ethanol and 4.0 mL of glacial acetic acid, stirred for 30 min, and then 5 mL of hydrogen with a concentration of 0.12 mol / L was added dropwise. Fluoric acid solution, stir to form a transparent mixed solution A; mix 5ml of ammonia water with a concentration of 0.12 mol / L and 10ml of ethanol, add 0.3636g (9×10 -4 mol) ferric nitrate, adjust the pH to 2 with 1.0 mol / L nitric acid, and prepare solution B; slowly drop solution B into solution A to obtain a uniform transparent sol; place it in the air for 24 h to obtain a solid gel; Dry at 80°C for 12 h, grind into powder, place in a muffle furnace at 500°C, and bake for 60 min to obtain iron, nitrogen and fluoride co-doped TiO 2 Photocatalyst, labeled as Fe-N-F-TiO 2 . The molar ratio of Fe to Ti ...

Embodiment 2

[0035] Example 2 Iron Nitrogen Fluoride Co-doped TiO 2 catalyst of light

[0036] (1) Preparation method

[0037] Under rapid stirring, 10 mL (0.03 mol) of butyl titanate was slowly dropped into a mixed solution of 30 mL of ethanol and 4.0 mL of glacial acetic acid, and stirred for 30 min; then 5 mL of hydrogen with a concentration of 0.12 mol / L was added dropwise Fluoric acid solution, stir to form a transparent mixed solution A; mix 5 ml of ammonia water with a concentration of 0.12 mol / L and 10 ml of ethanol, add 0.1212 g (3.0×10 -4 mol), 0.2424 g (6.0×10 -4 mol), 0.3636g (9.0×10 -4 mol), 0.4848g (1.2×10 -3 mol) of ferric nitrate, adjust the pH to 2 with 1mol / L nitric acid, and make solution B. Solution B was slowly dropped into solution A to obtain a uniform transparent sol. Placed in the air for 24 h to obtain a solid gel, dried at 80 °C for 12 h, ground into powder, and then placed in a muffle furnace at 500 °C for 60 min to obtain a molar ratio of N to Ti...

Embodiment 3

[0043] Example 3 Iron Nitrogen Fluoride Co-doped TiO 2 catalyst of light

[0044] (1) Preparation method

[0045] The method is the same as that of Example 1, except for the difference: in a muffle furnace, roast at 300°C, 400°C, 500°C, 600°C and 700°C for 60 min.

[0046] (2) Degradation experiment

[0047] The concentration of BPA was adjusted to 10.0 mg / L, and the pH was 5.7; 2.0 g / L of iron, nitrogen and fluoride co-doped titanium dioxide photocatalyst was added; the visible light power was 128 W, and the irradiation time was 3.0 h. The degradation rate is shown in Table 3.

[0048] table 3

[0049] Heat treatment temperature (℃) Degradation rate% (276nm) 300 100(removal rate) 400 78.1 500 76.71 600 15.6 700 18.6

[0050] It can be seen from Table 3 that when the calcination temperature is 300°C, BPA is completely removed. This is because at lower temperatures, TiO 2 The crystallization has not been completed, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com