Coal-fired flue gas desulphurization denitration process and desulphurization denitration device thereof

A technology for desulfurization and denitrification and coal-fired flue gas is applied in the field of desulfurization and denitrification, which can solve the problems of slow progress of ammonia wet denitrification, low removal rate of ammonia wet denitrification, and low solubility of reaction activity, achieving high absorption rate and easy management. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

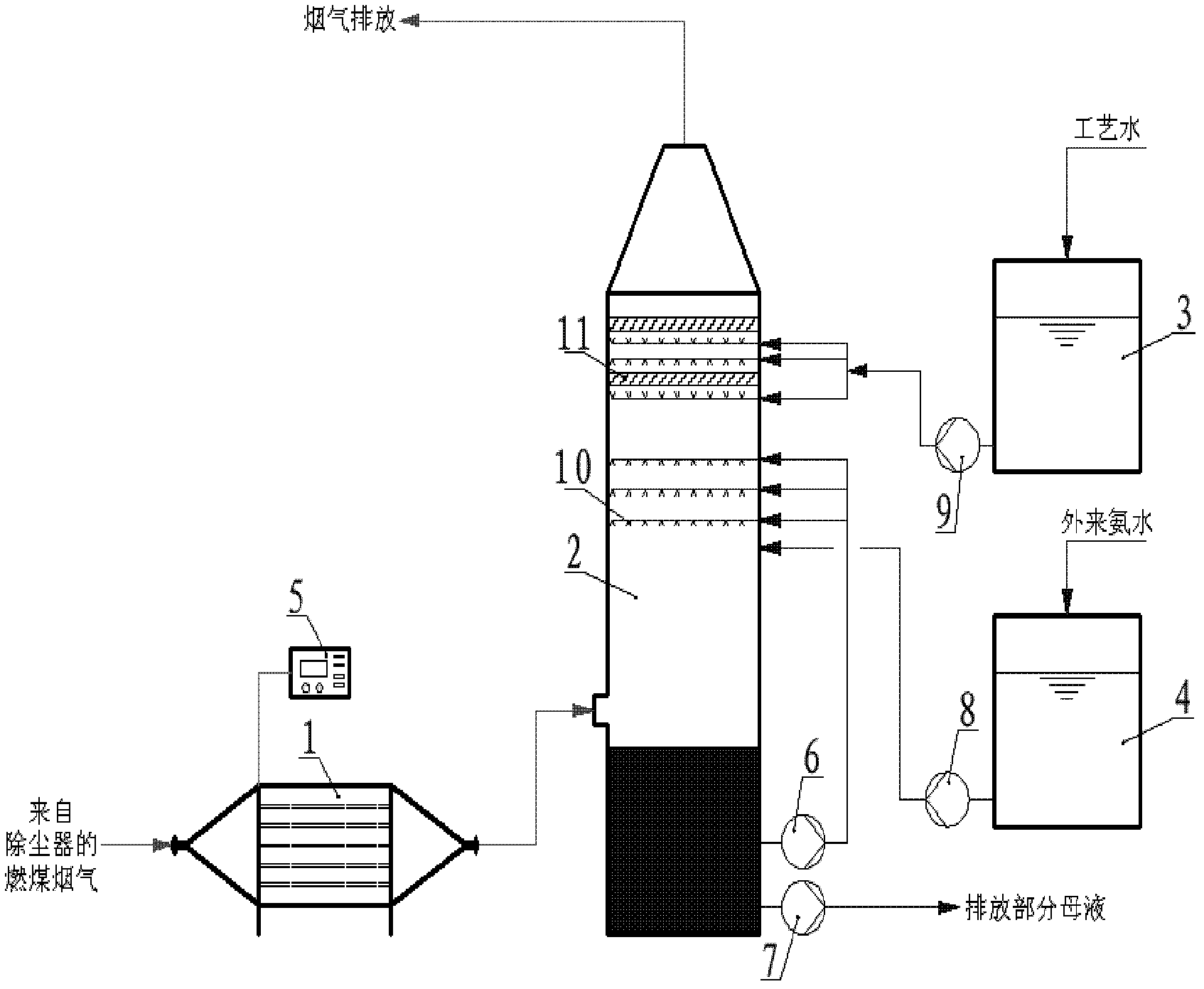

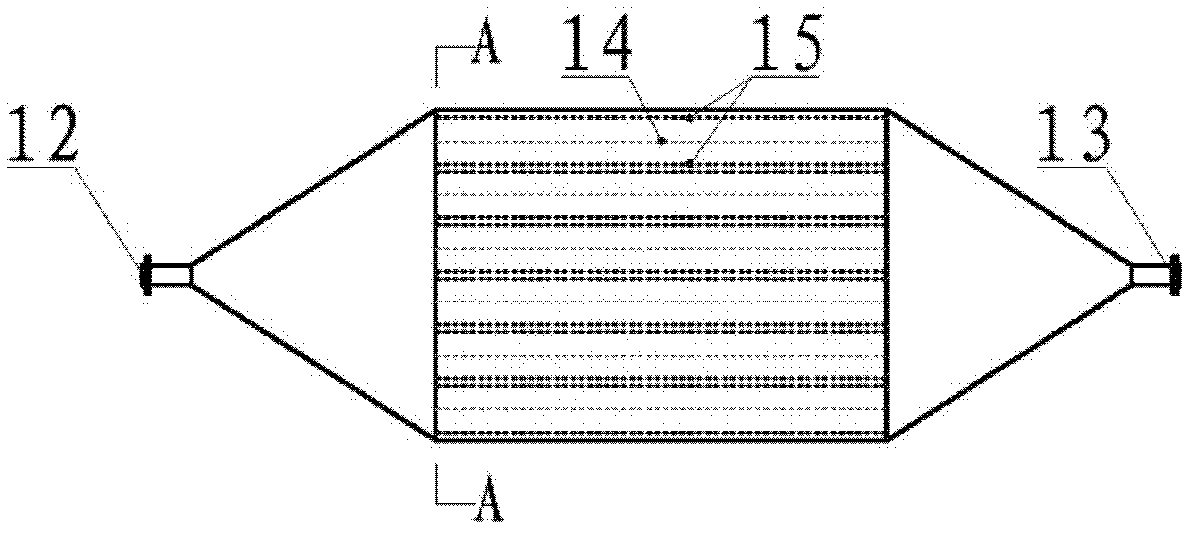

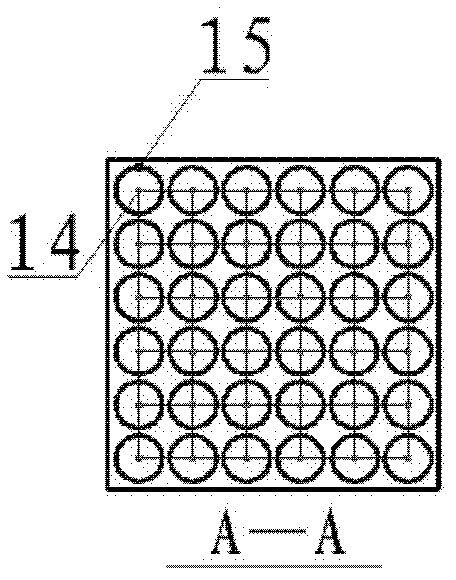

[0027] This embodiment provides a coal-fired flue gas desulfurization and denitrification process and its desulfurization and denitrification device, and its device structure is as follows figure 1 As shown, it mainly includes low-temperature plasma reactor 1, simultaneous desulfurization and denitration spray tower 2, process water tank 3, ammonia tank 4, pulse power supply 5, absorption liquid circulation pump 6, mother liquor transfer pump 7, ammonia water pump 8 and process water pump 9 , The outlet of the low-temperature plasma reactor 1 is connected with the inlet of the simultaneous desulfurization and denitration spray tower 2, and the absorption liquid at the bottom of the desulfurization and denitration spray tower 2 is re-sent into the spray device through the absorption liquid circulation pump 6. Part of it is discharged through the mother liquor transfer pump 7 installed at the bottom of the simultaneous desulfurization and denitration spray tower. The process water ...

Embodiment 2

[0031] The device structure of this embodiment is the same as that of embodiment 1, the difference is that the process flow of this embodiment is: the coal-fired flue gas at 180°C from the dust collector enters the low-temperature plasma reactor 1 through the flue, and SO in the coal-fired flue gas 2 The concentration is 2000mg / Nm 3 , NO x The concentration is 800mg / N m 3 , The discharge processing power in the low-temperature plasma reactor is 4W / m 3 , The residence time of flue gas is 3.5 seconds. In the reactor, 40%-50% of NO in coal-fired flue gas is oxidized to NO 2 , Making NO and NO in the flue gas 2 The number of molecules is close to 1:1. The conditioned flue gas enters the simultaneous desulfurization and denitrification spray tower 2, the empty tower gas velocity of the flue gas is 3.5m / s, the absorption liquid used is ammonia with a concentration of 10%, the liquid-gas ratio is 6L / m3, and the ammonia is sprayed The atomizing nozzle of the shower system sprays out and ...

Embodiment 3

[0033] The device structure of this embodiment is the same as that of embodiment 1, the difference is that the process flow of this embodiment is: the coal-fired flue gas at 200°C from the dust collector enters the low-temperature plasma reactor 1 through the flue, and SO in the coal-fired flue gas 2 The concentration is 2600mg / N m 3 , NO x The concentration is 700mg / N m 3 , The discharge processing power in the low-temperature plasma reactor is 4W / m 3 , The residence time of the flue gas is 4 seconds. In the reactor, 40%-50% of the NO in the coal-fired flue gas is oxidized to NO 2 , Making NO and NO in the flue gas 2 The number of molecules is close to 1:1. The conditioned flue gas enters the simultaneous desulfurization and denitrification spray tower 2, the empty tower gas velocity of the flue gas is 3.5m / s, the absorption liquid used is ammonia with a concentration of 10%, and the liquid-gas ratio is 6.5L / m3. The atomizing nozzle of the spray system sprays out, and it comes i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com