Chitin fiber reinforced polylactic acid three-dimensional porous support material and preparation method

A technology of chitin fiber and scaffold material, which is applied in the field of chitin fiber reinforced polylactic acid three-dimensional porous scaffold material and preparation, and repair of bone tissue defects, can solve problems such as pH drop, and achieve good biocompatibility and mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

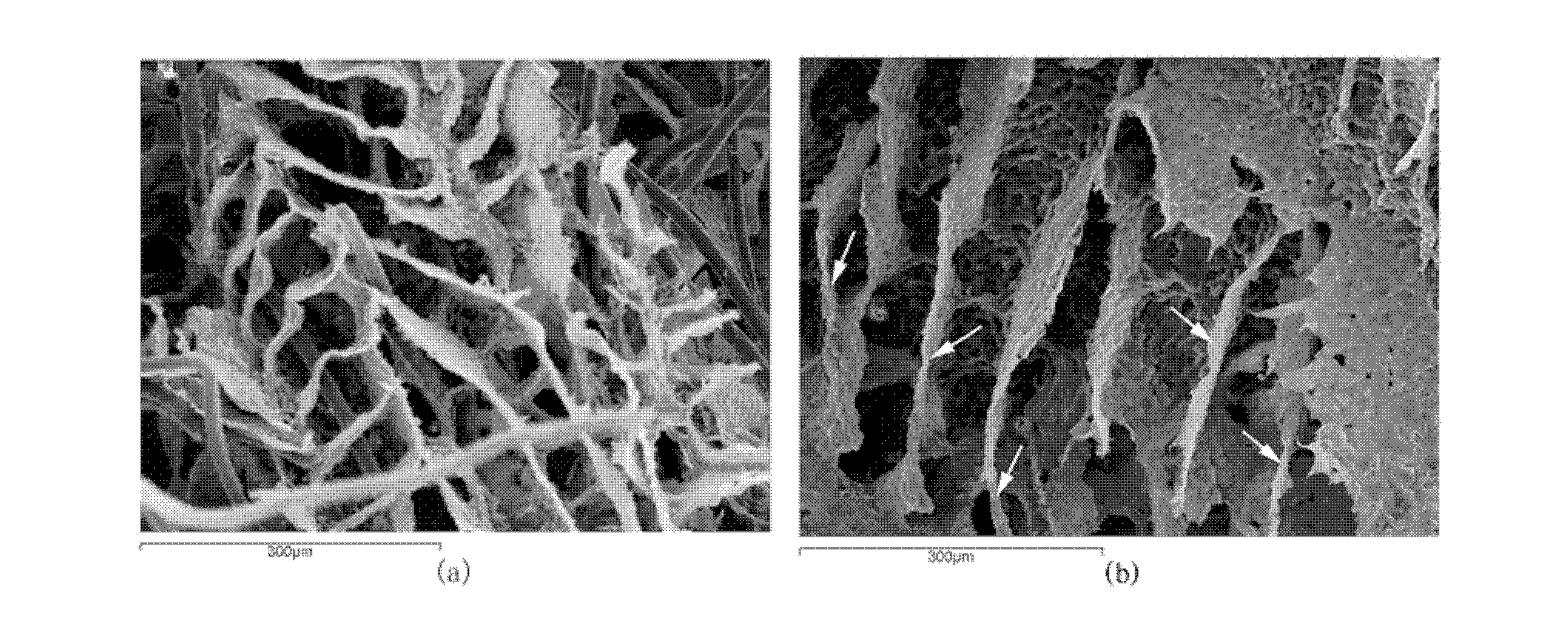

[0037] Example 1: Preparation of chitin fiber reinforced polylactic acid three-dimensional porous scaffold material without protein crosslinking

[0038] (1) Dissolve 6g of polylactic acid PLA in 1,4-dioxane to prepare a solution with a concentration of 100g / L. Then add the chitin fiber CF that has not been cross-linked with PLA PLA in volume content of 30%, and then magnetically stir at room temperature for 2 hours and ultrasonically disperse for 4 hours to obtain uncrosslinked polylactic acid / chitin fiber Mix the liquid.

[0039] (2) Pour the mixed solution prepared in the first step into a polytetrafluoroethylene mold, place it in a refrigerator at -20°C and freeze for 24 hours, then transfer the mold to a freeze dryer for freeze drying for 36 hours.

[0040] (3) Dry the freeze-dried material obtained in the second step in a vacuum drying oven at 50°C for 18 hours.

[0041] (4) The material is sterilized with ethylene oxide steam for 5 hours to obtain a three-dimensional porous sc...

Embodiment 2

[0042] Example 2: Preparation of protein-crosslinked chitin fiber reinforced polylactic acid three-dimensional porous scaffold material

[0043] (1) Dissolve 5 g of chitin fiber CF with a length of 1.1 mm, 15 g of polylactic acid PLA, and 4 g of cross-linking agent N, N'-dicyclohexyl carboimide DCC in dichloromethane at 0°C After 4 hours of magnetic stirring, leave it for 24 hours, then take the CF out of the solution and wash it with dichloromethane three times and deionized water three times, and then dry it in a vacuum drying oven at 40°C to obtain a cross-linked polylactic acid PLA. Linked chitin fiber CF.

[0044] (2) Dissolve 6 g of polylactic acid PLA in 1,4-dioxane to prepare a solution with a concentration of 50 g / L. Then add the chitin fiber CF that has been cross-linked with PLA in the first step with a volume content of 35%. After 2 hours of magnetic stirring and ultrasonic dispersion for 4 hours at room temperature, cross-linked polylactic acid / chitin is prepared. Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com