Method for preparing tobacco flavors from tobacco waste

A technology for tobacco flavor and tobacco powder, which is applied in the directions of tobacco, application, and treatment of tobacco, can solve the problems of increasing process complexity and increasing production cost, and achieves the effects of enhancing the rich aroma, low cost and comfortable taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

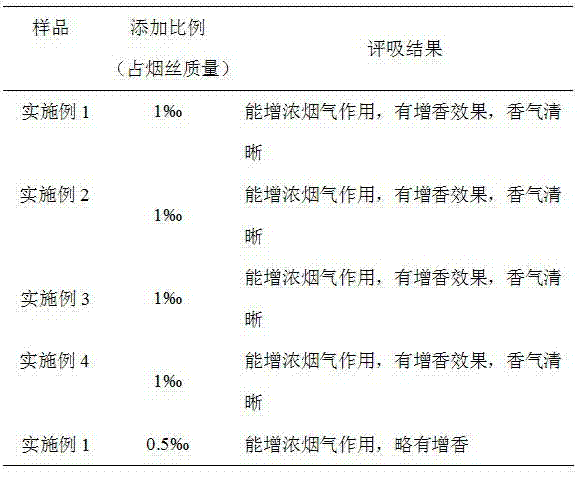

Embodiment 1

[0025] The tobacco powder is pulverized by a pulverizer, passed through a 120-mesh sieve, weighed 60 kilograms of tobacco powder, added 180 kilograms of water, the material liquid is uniformly dispersed, added potassium hydroxide to adjust the pH value to 8, the temperature of the autoclave is 110 ° C, and the processing time is Extract for 1 hour to obtain the extract (wherein the protein recovery rate can reach 58.9%), adjust the pH value of the extract to 4.5 with citric acid, add ethanol until the volume concentration of ethanol in the system reaches 30%, reflux the condenser tube for extraction, and heat to boiling , keep slightly boiling during the extraction process, the extraction time is 1 hour, suction filtration, remove insoluble impurities, obtain the supernatant, the supernatant is concentrated in vacuum to a solid content of 40% by weight, and the temperature during the concentration is controlled at 55-60 ℃, the vacuum degree is controlled at 0.05-0.1 MPa, and 69...

Embodiment 2

[0030] The tobacco powder is pulverized by a pulverizer, passed through a 80-mesh sieve, weighed 120 kg of tobacco powder, added 600 kg of water, the material liquid is evenly dispersed, added sodium hydroxide to adjust the pH value to 10, the temperature of the autoclave is 120 ° C, and the time is 1.5 Extract within 1 hour to obtain an extract (wherein the protein recovery rate can reach 62.5%), adjust the pH value of the extract to 5.0 with malic acid, add ethanol and glycerol (wherein glycerol accounts for 15% of the volume of ethanol) to the system organic The volume concentration of the solvent reaches 50%, the condenser tube is refluxed for extraction, heated to boiling, and kept slightly boiling during the extraction process, the extraction time is 2 hours, and the insoluble impurities are removed by suction filtration to obtain the supernatant, which is vacuum concentrated to the weight of the solid The content is 50%, wherein the heating temperature is controlled at 5...

Embodiment 3

[0032] The tobacco powder is pulverized by a pulverizer and passed through a 10-mesh sieve. Weigh 80 kg of tobacco powder and add 800 kg of water. The feed liquid is evenly dispersed. Add potassium hydroxide to adjust the pH value to 12. Extract for 2.5 hours to obtain the extract (wherein the protein recovery rate can reach 65.8%), adjust the pH value of the extract to 5.5 with lactic acid, add ethanol and propylene glycol (wherein the amount of propylene glycol accounts for 20% of the volume of ethanol) to the system organic solvent When the volume concentration reaches 70%, the condenser tube is refluxed for extraction, heated to boiling, kept slightly boiling during the extraction process, refluxed for 3 hours, suction filtered, and insoluble impurities are removed to obtain a supernatant, which is concentrated in vacuum to a solid weight content of 55%, wherein the heating temperature is controlled at 55-60°C during the concentration process, and the vacuum degree is maint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com