Wafer bearing structure and preparation method thereof, and wafer thinning method

A wafer carrying and wafer technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem that the wafer carrying structure cannot meet the requirements of TSV process, and reduce the requirements for surface flatness and reduce costs , The effect of saving process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

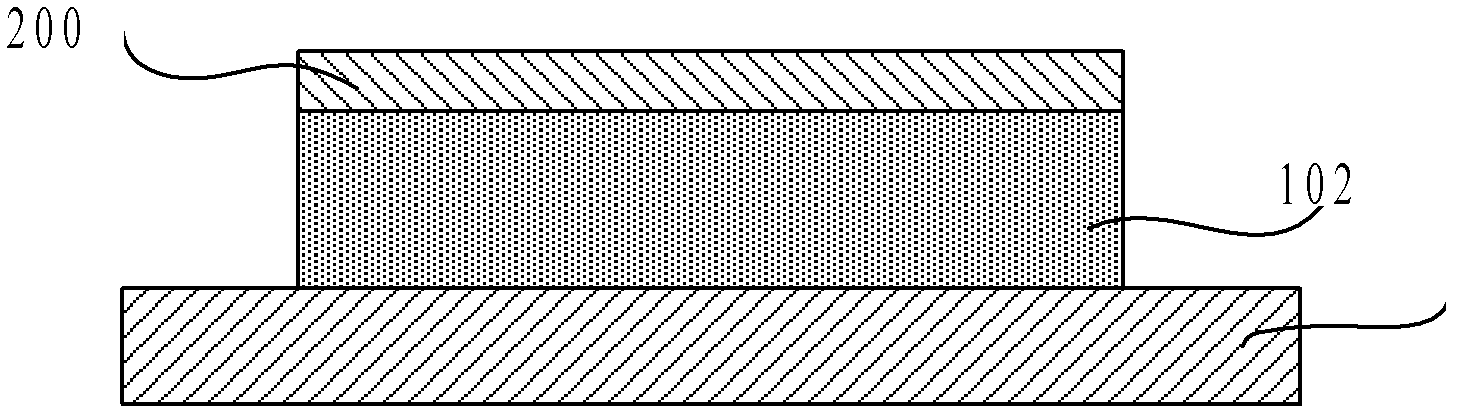

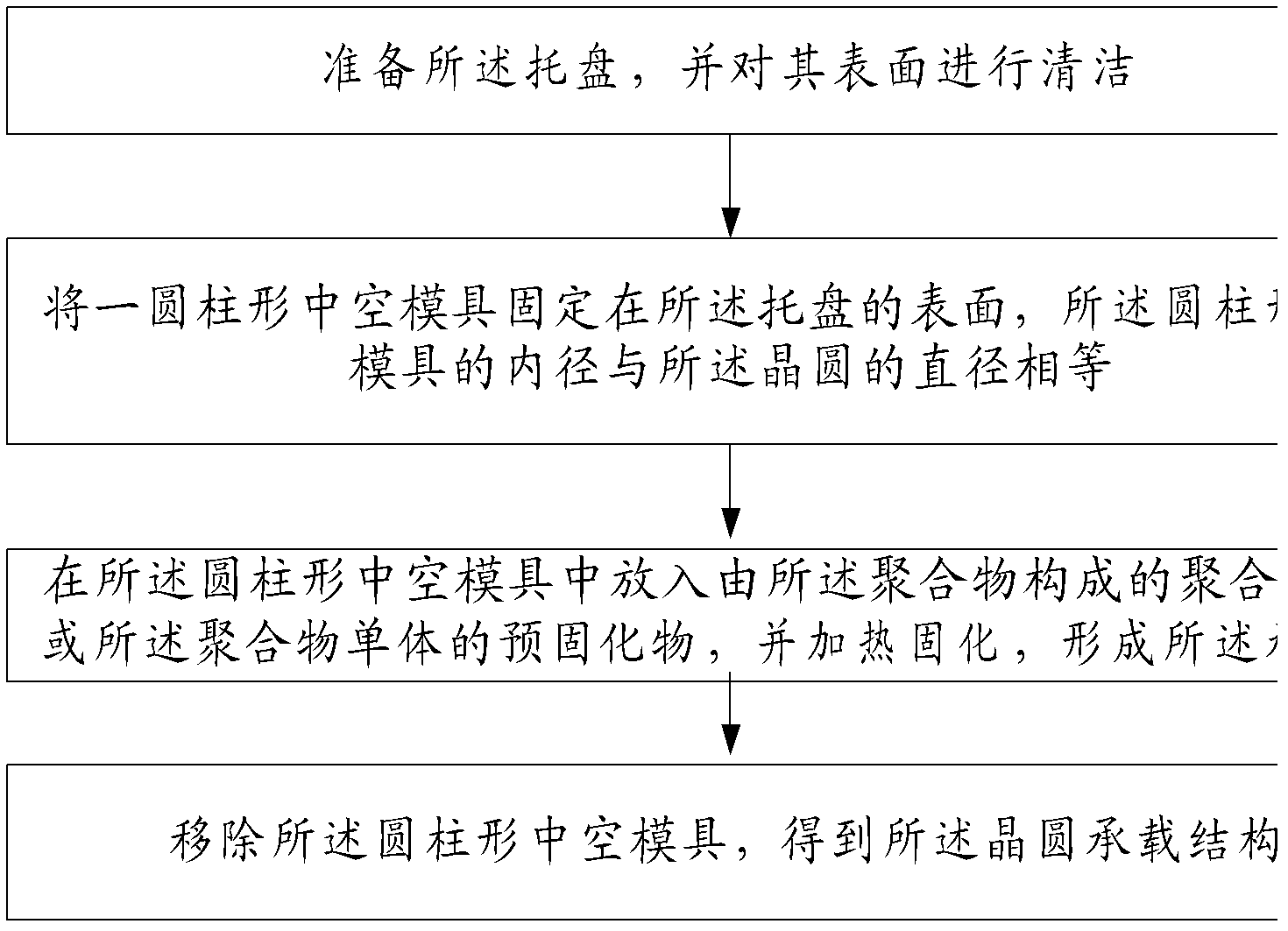

[0070] Please refer to figure 2 and Figure 3A to Figure 3D ,in, figure 2 A flow chart of the method for preparing the wafer carrying structure provided in the first embodiment of the present invention, Figure 3A to Figure 3D The sectional view of the wafer carrying structure corresponding to each step of the method for preparing the wafer carrying structure provided in the first embodiment of the present invention, combined with figure 2 and Figure 3A to Figure 3D , the preparation method of the wafer carrying structure provided by the first embodiment of the present invention includes the following steps:

[0071] S101, prepare the tray 101, and clean its surface, such as Figure 3A shown;

[0072] S102. Fix a cylindrical hollow mold 300 on the surface of the tray 101, the inner diameter of the cylindrical hollow mold 300 is equal to the diameter of the wafer, as Figure 3B Shown; Wherein, the height of described cylindrical hollow mold is 10~15mm.

[0073] S103....

Embodiment 2

[0076] The difference between embodiment 2 and embodiment 1 is that: the carrier plate is prepared first, and then the carrier plate is fixed on the tray, specifically, the carrier plate can be adhered to the tray . That is, the preparation method of the wafer carrying structure provided in Example 2 comprises the following steps:

[0077] Prepare the pallet and clean its surface;

[0078] Prepare the carrier plate; specifically, first prepare a cylindrical hollow mold, the inner diameter of the cylindrical hollow mold is equal to the diameter of the wafer; The polymer monomer or the pre-cured product of the polymer monomer is heated and cured to form the carrier plate; wherein, the height of the cylindrical hollow mold is 10-15 mm;

[0079] The carrier plate is adhered to the tray to form the wafer carrier structure.

[0080] Please continue to refer Figure 4 and Figure 5A to Figure 5D ,in, Figure 4 The flow chart of the wafer thinning method provided by the embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com