Super-conducting type controlled reactor with high leakage reactance

A high leakage reactance and reactor technology, applied in variable inductance/transformer, superconducting magnet/coil, usage of superconductor elements, etc., can solve problems such as inability to effectively adjust reactance value, achieve good linearity, reduce The effect of power consumption and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

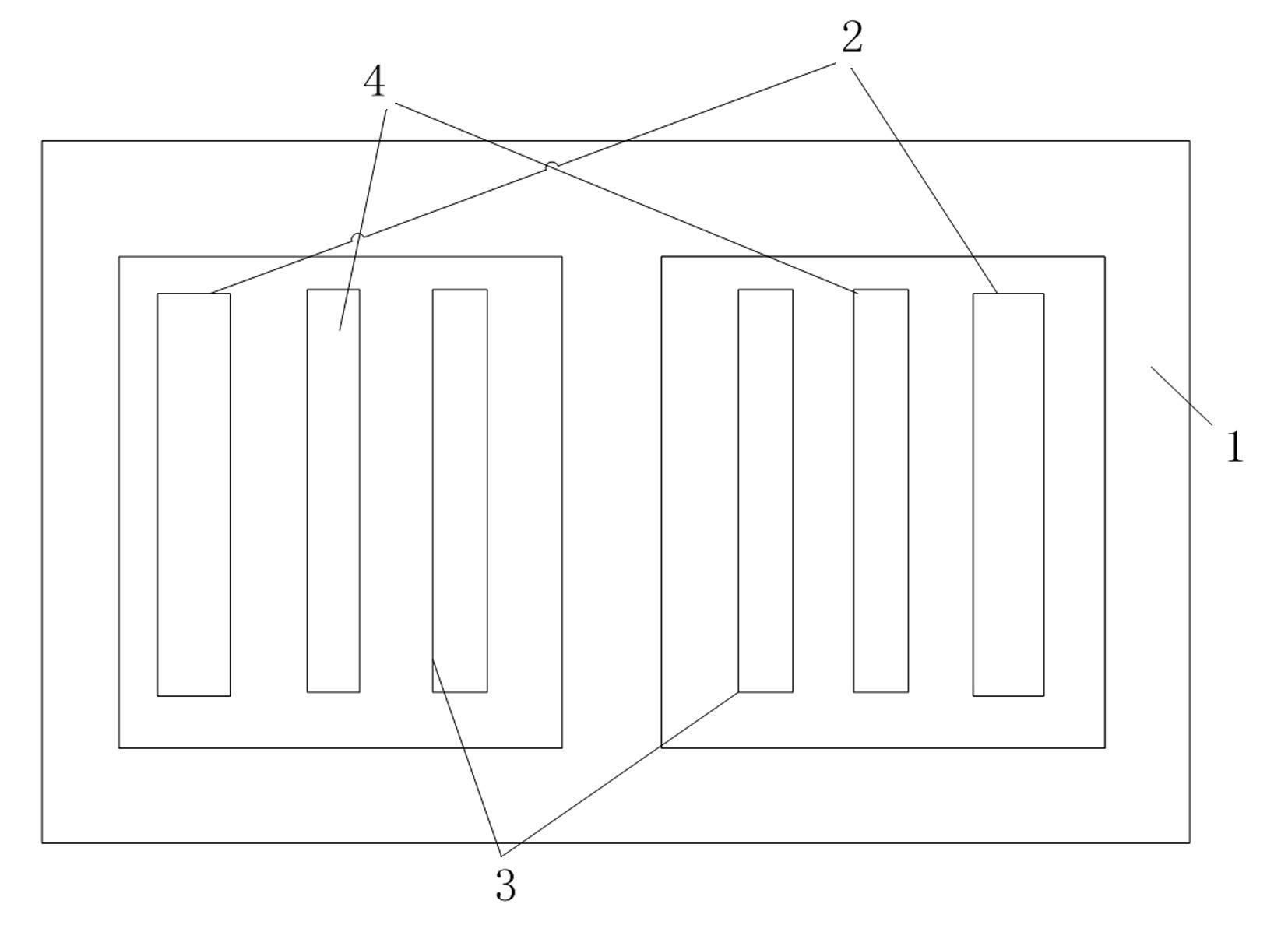

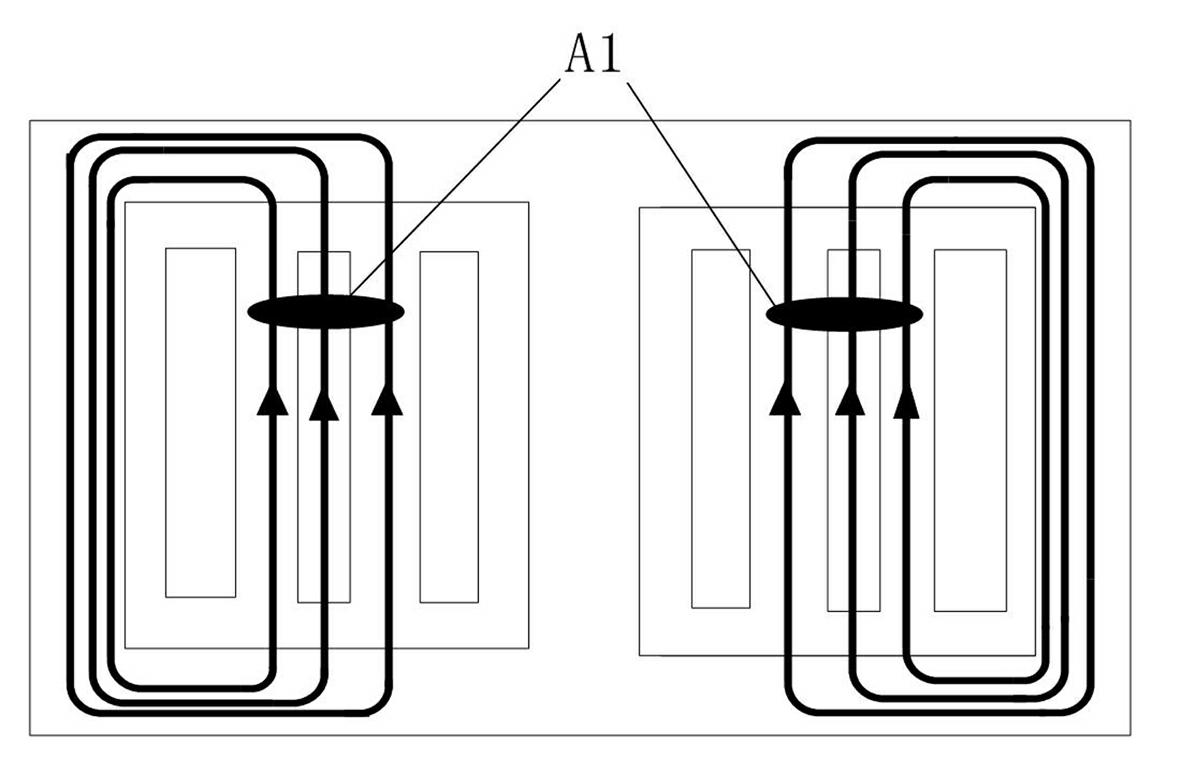

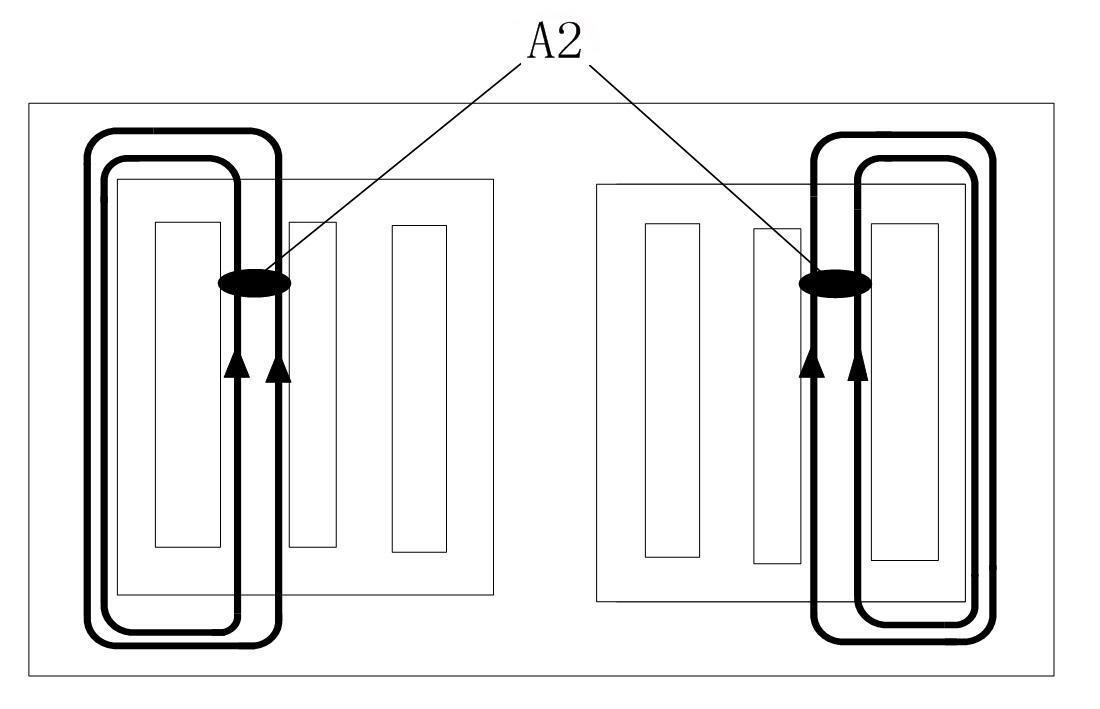

[0020] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention includes an iron core 1, a primary copper main coil 2, a secondary superconducting control winding a3, and a secondary superconducting control winding b4.

[0021] The three windings are wound on the same iron core 1, and the placement sequence of the three windings from outside to inside is: primary copper main coil 2, secondary superconducting control winding b4 and secondary superconducting control winding a3;

[0022] The primary copper main coil 2, the secondary superconducting control winding a3, and the secondary superconducting control winding b4 are independent of each other;

[0023] The primary copper main coil 2 is connected in parallel to the circuit, and the secondary superconducting control winding a3 and the secondary superconducting control winding b4 are closed windings controlled by bidirectional thyristor switches for short circuit and open circuit.

[0024] The mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com