Apparatus used for fabrication of printed circuit board

A technology for printed circuit boards and circuit boards, which can be used in photolithography process exposure devices, removal of conductive materials by chemical/electrolytic methods, and microlithography exposure equipment, etc. The effect of reducing equipment processing difficulty, improving production efficiency and expanding equipment adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the present invention more obvious and easy to understand, a preferred embodiment is described in detail as follows in conjunction with the accompanying drawings.

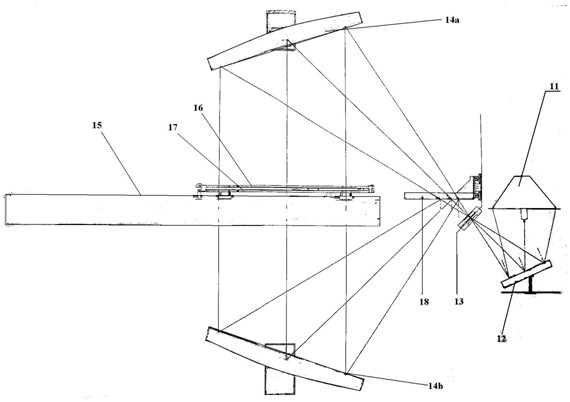

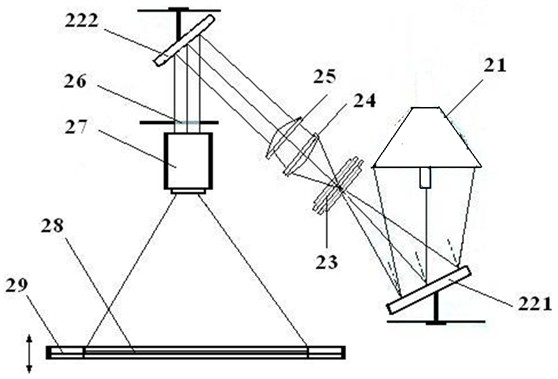

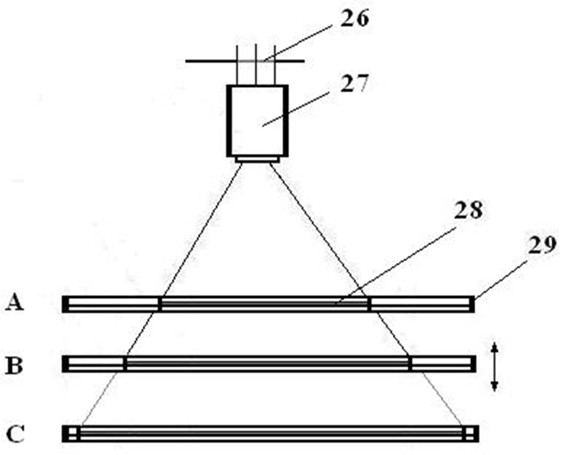

[0017] like figure 2 As shown, it is a schematic diagram of the optical path of a device for making a single-sided printed circuit board. In this embodiment, the device includes an ultraviolet light source generating device 21, and the ultraviolet light source generated by the ultraviolet light source generating device 21 is reflected by the first After being reflected by the mirror 221 , it is irradiated on the uniform light system 23 . The uniform light system 23 is usually composed of two fly-eye lens arrays, and can also be composed of an optical integrator rod. After the light is emitted from the homogenizing system 23, a uniform light spot proportional to the aperture of the homogenizing system 23 will be formed, and the light will pass through the first field mirror 24, the second f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com