Synchronous reckoning method of utility boiler efficiency and coal heat value as well as ash content and moisture content

A coal-fired calorific value and power plant boiler technology, applied in the field of soft measurement, can solve problems such as complex solution process and many measurement variables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

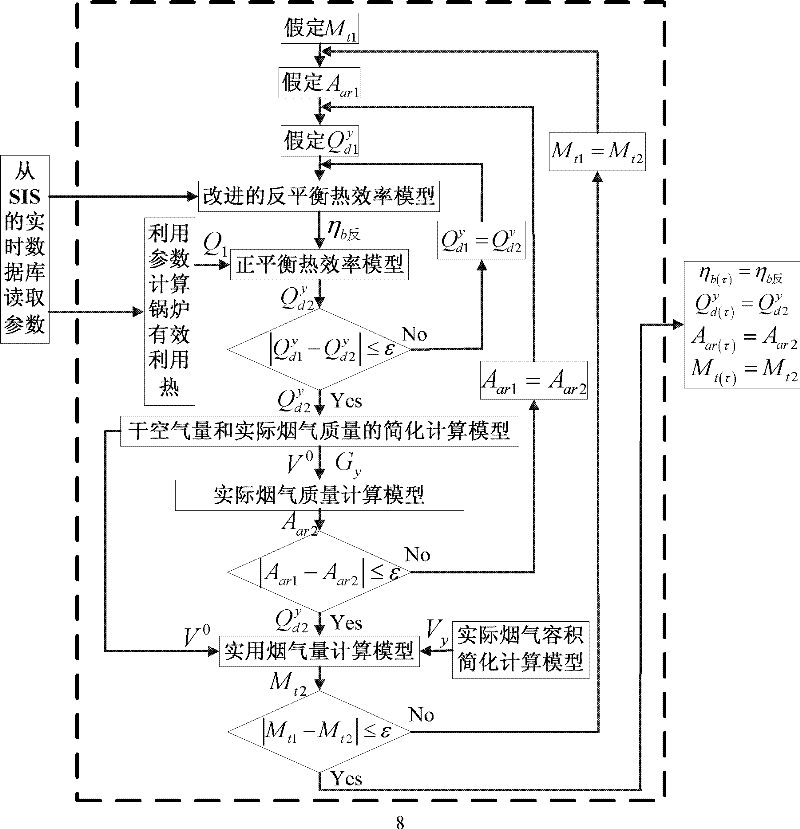

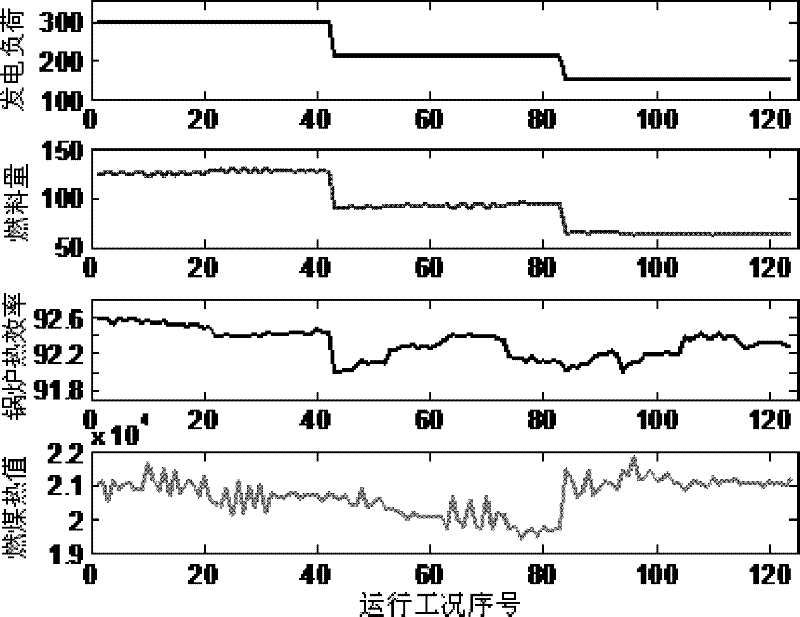

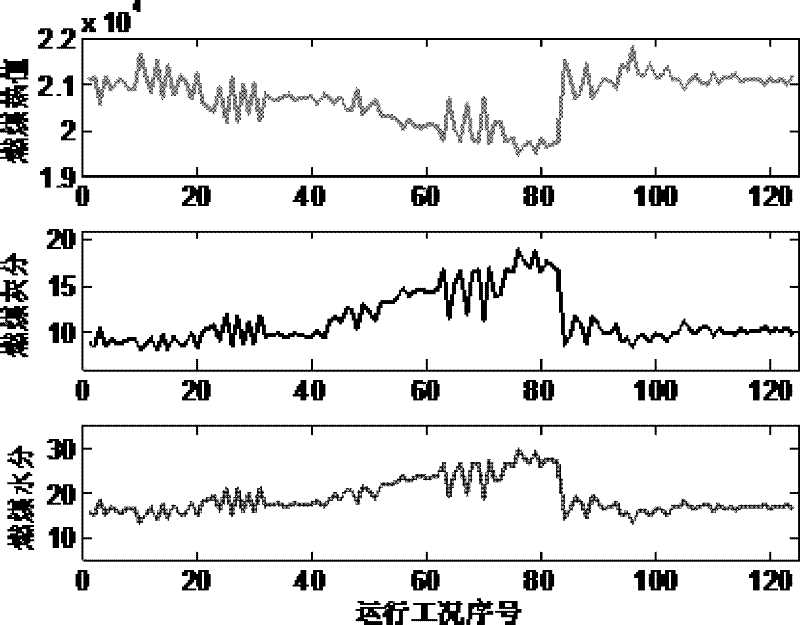

[0098] A simultaneous calculation method for utility boiler efficiency and coal-fired calorific value, ash content and moisture content,

[0099] Step 1: At time τ, use the real-time database of the plant-level monitoring information system (SIS) to read the supply air temperature t at that time lk , exhaust gas temperature t py , exhaust gas oxygen content O 2py , fly ash carbon content C fh , the amount of fuel into the furnace B, the evaporation of the boiler D, the power generation load of the unit Pel, and the main steam pressure p gr and temperature t gr , reheat steam inlet pressure p zrj and temperature t zrj , reheat steam outlet pressure p zrc and temperature t zrc , Water supply pressure p gs , feed water temperature t gs , Feedwater flow D gs , drum pressure p qb , Reheater desuperheating water injection volume D zrjw , and the extraction steam temperature t of each heater of the high-pressure cylinder of the steam turbine j , extraction pressure p j ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com