Pump control cvt electro-hydraulic control system

An electro-hydraulic control system, pump control technology, applied in transmission control, components with teeth, belts/chains/gears, etc., can solve problems such as CVT energy loss, reduce energy consumption, improve overall life and reliability Sexuality, the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

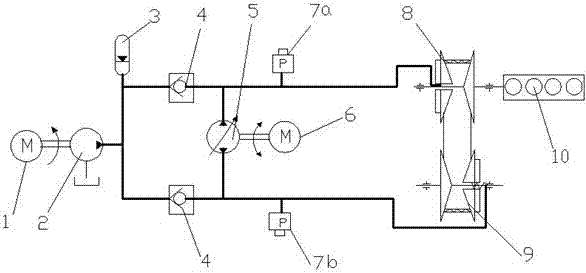

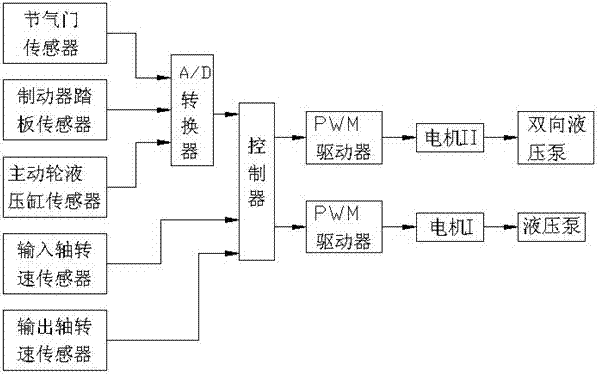

[0020] like figure 1 , 2 As shown, the pump-controlled CVT electro-hydraulic control system includes driving wheel hydraulic cylinder 8, driven wheel hydraulic cylinder 9, speed ratio control hydraulic circuit, clamping force control hydraulic circuit, controller, driving wheel hydraulic cylinder pressure sensor 7a and driven wheel Hydraulic cylinder pressure sensor 7b. The effective areas of the driving wheel hydraulic cylinder 8 and the driven wheel hydraulic cylinder 9 are equal. The speed ratio control hydraulic circuit includes a motor II6 and a two-way hydraulic pump 5, the motor II6 drives the two-way hydraulic pump 5, and the oil ports at both ends of the two-way hydraulic pump 5 communicate with the driving wheel hydraulic cylinder 8 and the driven wheel hydraulic cylinder 9 respectively. The clamping force control hydraulic circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com