Method and device for high-efficiency energy-saving desolvation of fossilized animal/plant wax-containing solution

A high-efficiency energy-saving, animal and plant technology, applied in the field of coal processing, can solve the problems of large heat energy consumption and large proportion of steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

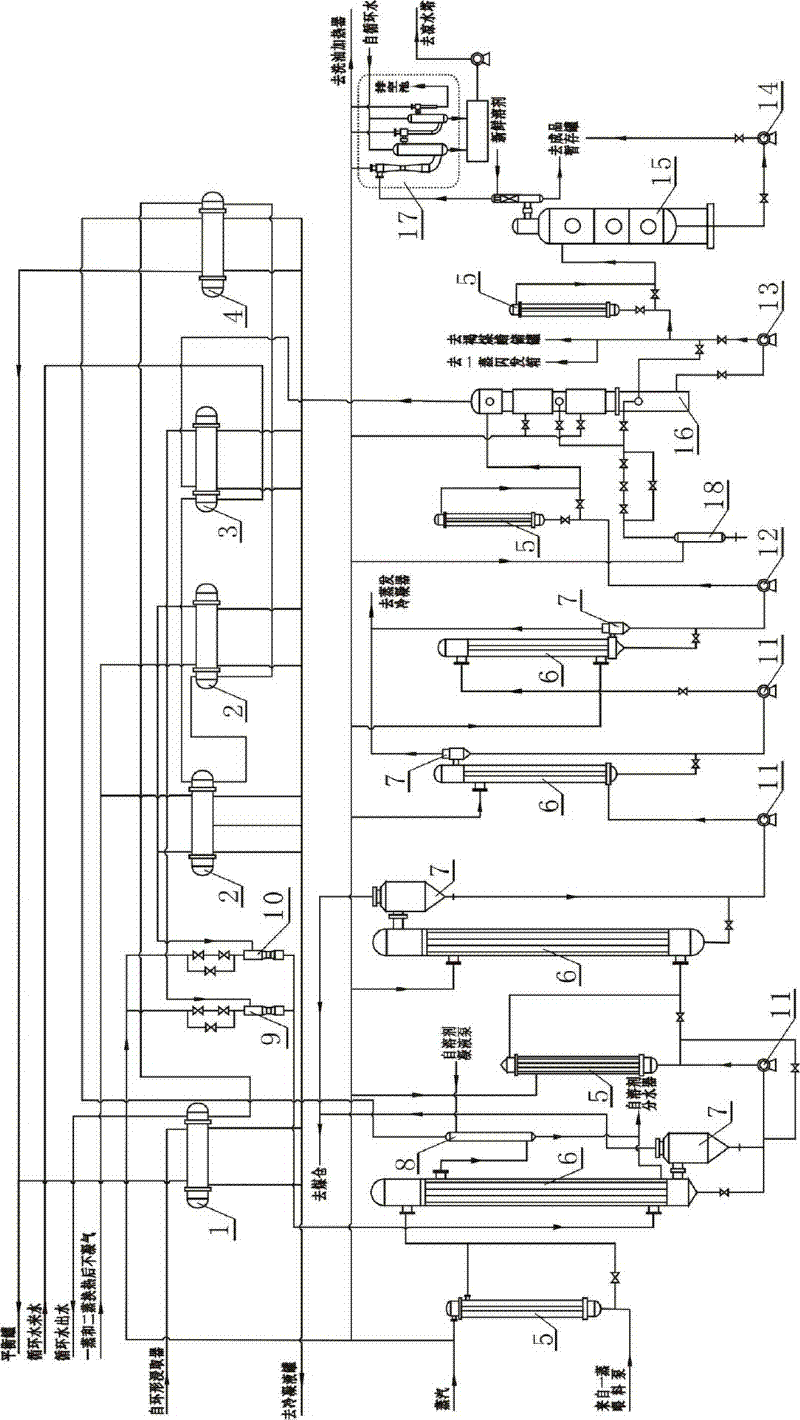

[0020] In the step A, the petrified animal and plant wax solution needs to be preheated before entering the primary and secondary evaporators; in the steps C and D, it needs to be preheated before entering the continuous stripping device and the continuous cooking device.

[0021] In the step A, the first and fourth stages of evaporation adopt falling film evaporation, and the second and third stages of evaporation adopt rising film evaporation.

[0022] Such as figure 1 As shown, the device of the present invention includes an evaporator 6 connected to a negative pressure system, a stripper 16 and a desolventization tower 15. The evaporator 6 is four stages, and the evaporator 6 of the first stage is connected to the residual coal removal Dissolved steam pipeline and evaporative feed pump 11, the evaporator 6 of the latter stage is connected through the process of evaporative feed pump 11 in turn; the outlet end of the solvent vapor of the first and second evaporator 6 is pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com