Modified acrylic resin as well as paint and application thereof

A technology of acrylic resin and isobornyl methacrylate, applied in the direction of coating, chemical recycling, etc., can solve the problems of damage to the performance of paint film, difficult to control the grafting process and grafting rate, inapplicability, etc., and achieve fast drying speed. , reduce the amount of catalyst, good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

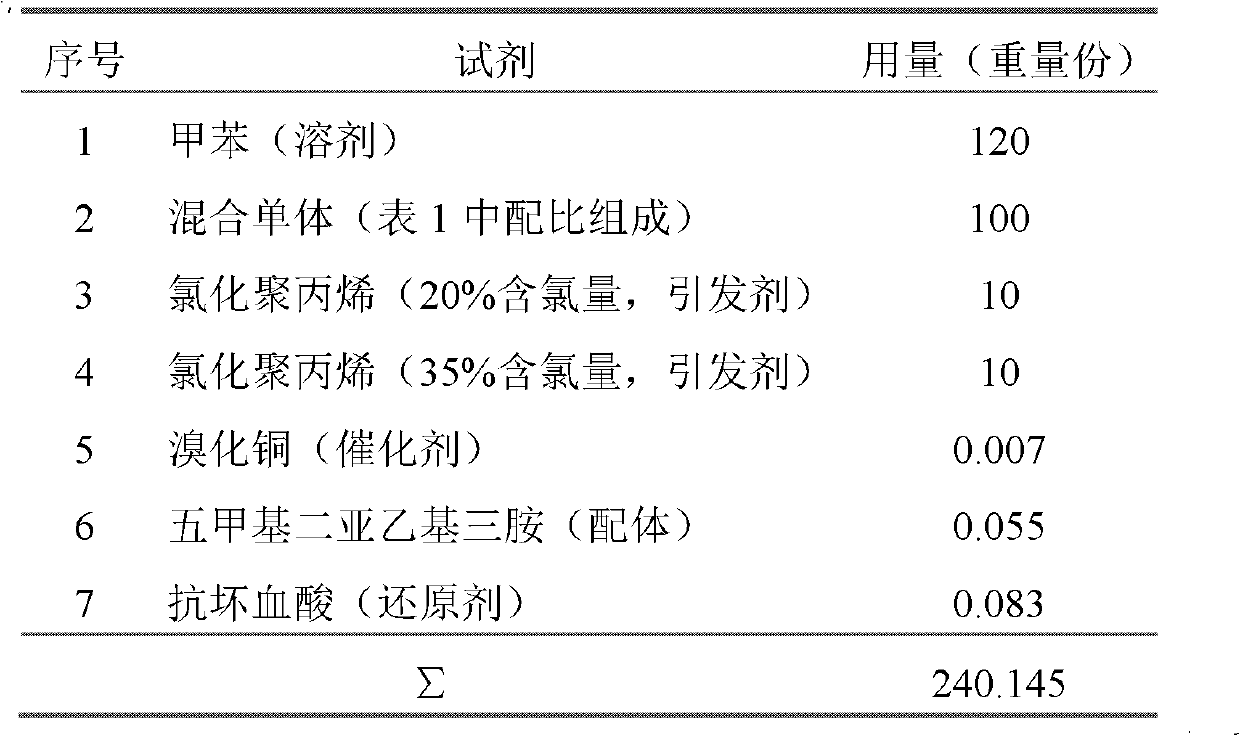

[0035] Preparation of Embodiment 1 Modified Acrylic Resin

[0036] First exhaust the air in the reaction system, pass inert gas, first dissolve the chlorinated polypropylene and half of the solvent at 75°C, and then put the catalyst, monomer, reducing agent, ligand, etc. into the reaction kettle, Stir the reaction at 75° C. for 10-25 h, and detect the conversion rate of the double bond by 1H-NMR nuclear magnetic resonance. If it reaches more than 80%, it is the end point of the reaction. After cooling down, diluting and discharging, the modified acrylic resin is obtained. The appearance of the obtained resin is light yellow transparent viscous liquid, the solid content is about 49.5%, and the viscosity is about 3000mPa·s (NDJ-1 rotational viscometer, 25°C) .

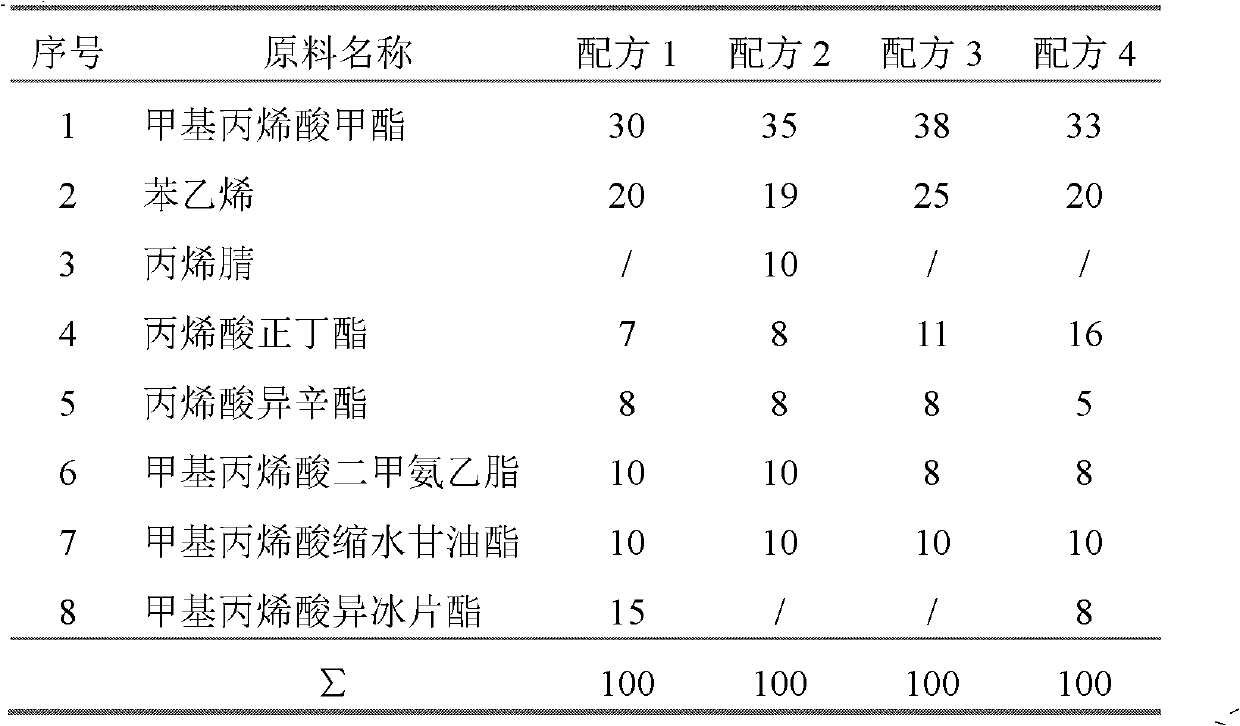

[0037] According to the above method, each component listed in Table 1 and its dosage (the values in the table are parts by weight) were weighed and mixed respectively, and the polymerization reaction was carried out ...

Embodiment 2

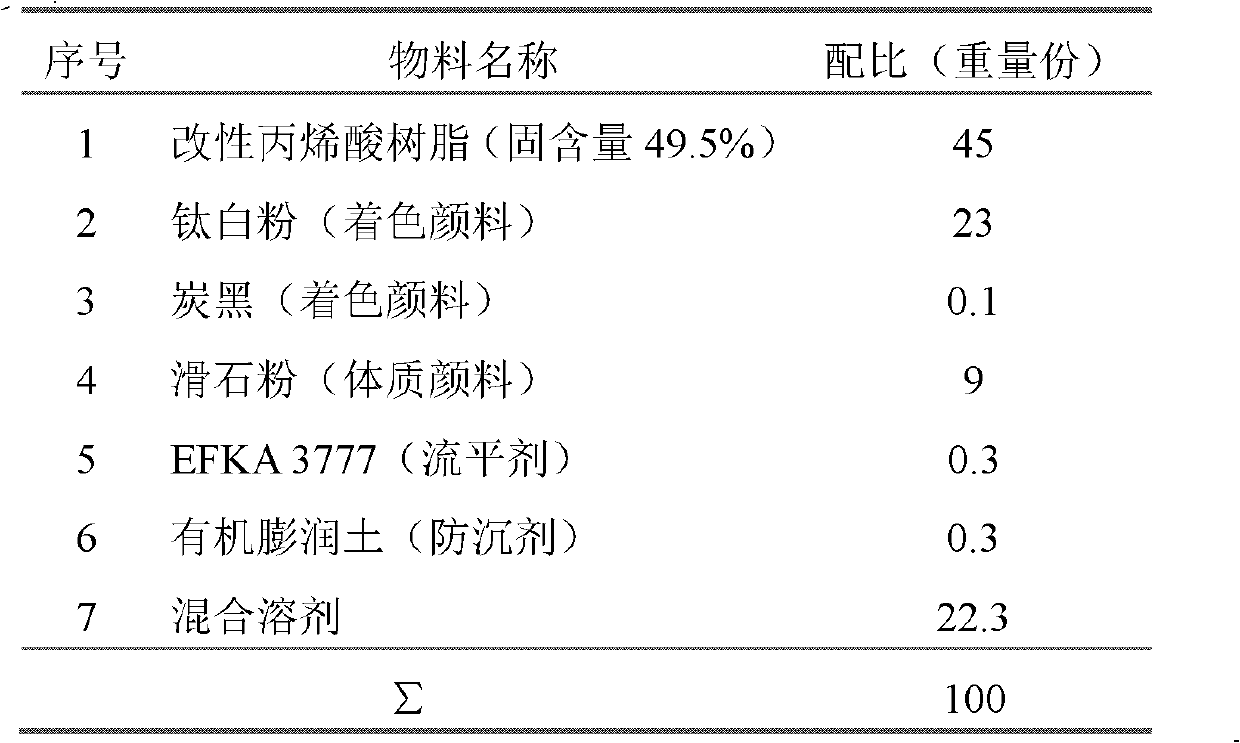

[0044] The preparation of embodiment 2 polypropylene plastic paint primer

[0045] Carry out batching preparation polypropylene plastic paint primer according to table 3.

[0046] table 3

[0047]

[0048] The mixed solvent in this embodiment is the general skill of those of ordinary skill in the art. The solvent type and proportion are adjusted according to the use environment and equipment conditions. Solvents include but are not limited to, toluene, xylene, butyl acetate, ethyl acetate, methyl ethyl ketone , butanone and cyclohexanone or one or more.

[0049] The solid content of the paint is (55±2)%, and the viscosity is (60-120)s (coating -4, 25°C).

[0050] The paint of the present invention is sprayed on the surface of polypropylene or modified polypropylene plastic and used as a primer, and the polyurethane topcoat can be resprayed to meet the specified performance requirements. First, spray the primer on the polypropylene plastic workpiece that has been wiped, l...

Embodiment 3

[0053] The preparation of embodiment 3 polypropylene plastic paint finish

[0054] Prepare polypropylene plastic paint topcoat according to Table 5

[0055] table 5

[0056]

[0057] The mixed solvent in this embodiment is the general skill of those of ordinary skill in the art. The solvent type and proportion are adjusted according to the use environment and equipment conditions. Solvents include but are not limited to, toluene, xylene, butyl acetate, ethyl acetate, methyl ethyl ketone , butanone and cyclohexanone or one or more.

[0058] Coating solid content (61±2)%, viscosity (60-120)s (coating -4, 25 ℃).

[0059] The paint of the invention is directly sprayed on the surface of polypropylene or modified polypropylene plastic, and used as a single-coat topcoat to meet specified performance requirements. First, spray polypropylene plastic paint topcoat on the polypropylene plastic workpiece that has been wiped, level it for 10-15 minutes, bake it at 80°C for 30 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com