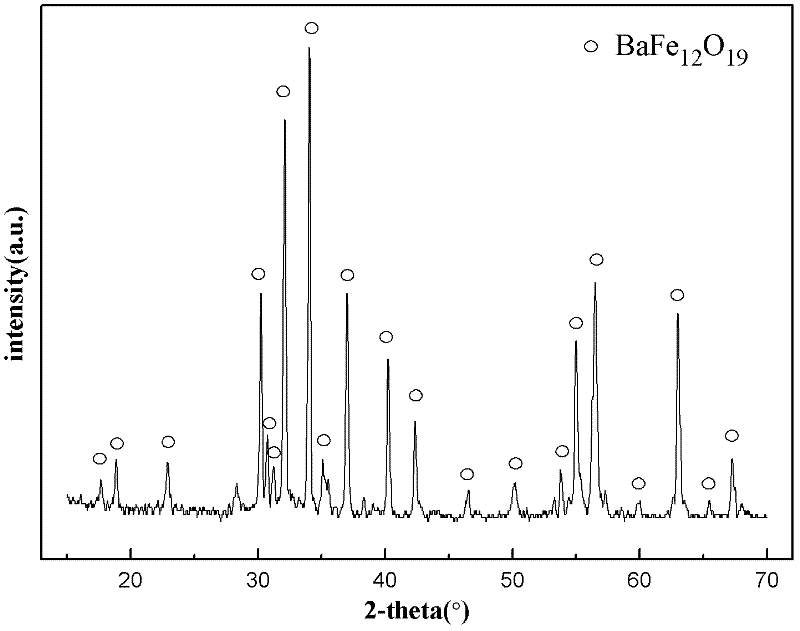

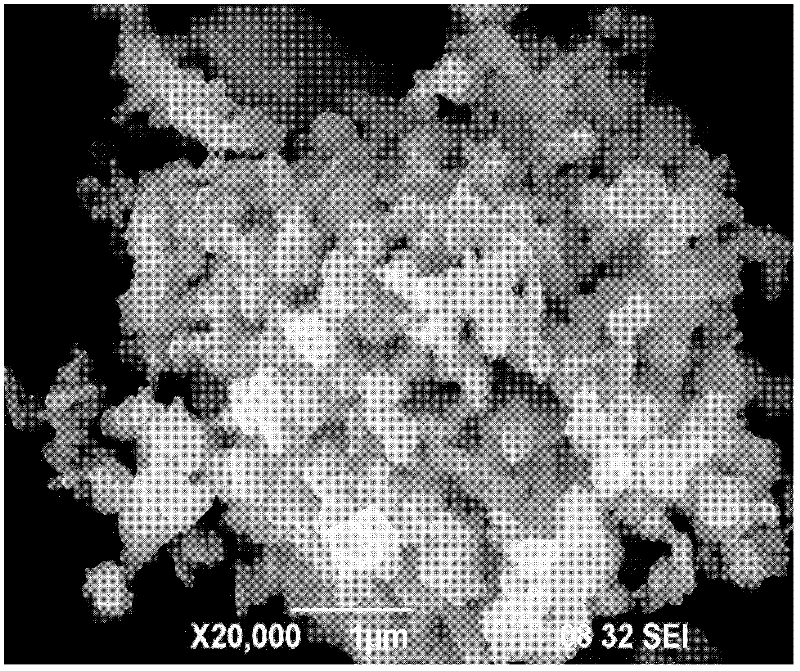

Method for preparing hexagonal BeFe12O19 (barium ferrite) magnetic nano powder by microwave-hydrothemal method

A technology of befe12o19 and microwave hydrothermal method, applied in nanotechnology, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of complex process, complicated operation, poor repeatability, etc., and achieve low preparation cost, simple operation and fast speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Step 1: Analytical pure barium nitrate and ferric nitrate nonahydrate are respectively configured into uniform solution A and uniform solution B of 0.01mol / L and 0.06mol / L;

[0015] Step 2: According to the Ba / Fe molar ratio of 1:6, add the B solution to the A solution, stir evenly, adjust the pH value to 8-13, and form a uniform co-precipitation precursor C;

[0016] Step 3: Pour the co-precipitation precursor C into the microwave hydrothermal reaction kettle, and the filling degree is controlled at 40%; then seal the reaction tank, put it into a microwave digestion instrument for multi-step reaction, and keep it warm at 100°C for 5 minutes, Insulate at 125°C for 5 minutes, at 150°C for 10 minutes, at 175°C for 15 minutes, at 180°C for 30 minutes, and cool to room temperature after the reaction is complete;

[0017] Step 4: Open the hydrothermal reaction tank, take out the material in the reaction tank and rinse with deionized water until the pH is 7, then calcinate at...

Embodiment 2

[0019] Step 1: Analytical pure barium nitrate and ferric nitrate nonahydrate are respectively configured into uniform solution A and uniform solution B of 0.01mol / L and 0.07mol / L;

[0020] Step 2: According to the Ba / Fe molar ratio of 1:7, add the B solution to the A solution, stir evenly, adjust the pH value to 9-12 respectively, and form a uniform co-precipitation precursor C;

[0021] Step 3: Pour the co-precipitation precursor C into the microwave hydrothermal reaction kettle, and the filling degree is controlled at 40%; then seal the reaction tank, put it into a microwave digestion instrument for multi-step reaction, and keep it warm at 100°C for 5 minutes, Insulate at 125°C for 5 minutes, at 150°C for 1 minute, at 175°C for 15 minutes, at 180°C for 30 minutes, and cool to room temperature after the reaction is complete;

[0022] Step 4: Open the hydrothermal reaction tank, take out the materials in the reaction tank and rinse with deionized water until the pH is 7, and f...

Embodiment 3

[0024] Step 1: Analytical pure barium nitrate and ferric nitrate nonahydrate are respectively configured into uniform solution A and uniform solution B of 0.01mol / L and 0.08mol / L;

[0025] Step 2: According to the Ba / Fe molar ratio of 1:8, add the B solution to the A solution, stir evenly, adjust the pH value to 10-13 respectively, and form a uniform co-precipitation precursor C;

[0026] Step 3: Pour the co-precipitation precursor C into the microwave hydrothermal reaction kettle, and the filling degree is controlled at 40%; then seal the reaction tank, put it into a microwave digestion instrument for multi-step reaction, and keep it warm at 100°C for 5 minutes, Insulate at 125°C for 5 minutes, at 150°C for 1 minute, at 175°C for 15 minutes, at 180°C for 30 minutes, and cool to room temperature after the reaction is complete;

[0027] Step 4: Open the hydrothermal reaction tank, take out the materials in the reaction tank and rinse with deionized water until the pH is 7, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com