Preparation method of reduced graphene oxide

A technology of graphene and graphite, which is applied in the field of graphene, can solve problems such as affecting the electrical properties of graphene, unfavorable health of operators, high toxicity of reducing agents, etc., and achieve good reduction performance, high environmental protection performance, and easy post-processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The embodiment of the invention discloses a method for preparing graphene, comprising the following steps:

[0027] a), under the condition of ultrasonic vibration, graphite oxide is dispersed in water to obtain colloid;

[0028] b) Under acidic or alkaline conditions, using zinc as a reducing agent to reduce the graphite oxide to obtain graphene; the weight ratio of the graphite oxide to zinc is 1: (5.5-6.5).

[0029] The above method is to disperse graphite oxide in water by ultrasonic vibration to obtain colloid, and then use zinc as a reducing agent to reduce graphite oxide. Since zinc is an amphoteric metal, it can play a reducing role in acidic or alkaline conditions. The reduction reaction can be carried out under both acidic and basic conditions. The advantage of preparing graphene under acidic conditions is that the product has high purity, simple purification steps, and easy post-treatment; the advantage of preparing graphene under alkaline conditions is that...

Embodiment 1

[0050] Embodiment 1 prepares graphite oxide

[0051] 1. Rinse the graphite powder with distilled water, pour off the suspended matter in the upper layer, filter and dry;

[0052] 2. Take 5g of dried graphite and 230mL of 98% concentrated sulfuric acid, mix them in an ice bath, stir for 15min, and make them fully mixed. Weigh 30g of KMnO 4 After adding the above mixed solution and continuing to stir for 2 hours, move it into a medium temperature water bath at 35°C and continue stirring for 30 minutes, slowly add 460ml of distilled water into the reaction system, then place it in an oil bath at 98°C for 15 minutes, then add 1400ml of warm water, and then add 100ml of 30 %H 2 o 2 , the product was centrifuged, washed with 2L 5% HCl solution, washed with water until pH ≈ 5, and dried to obtain graphite oxide.

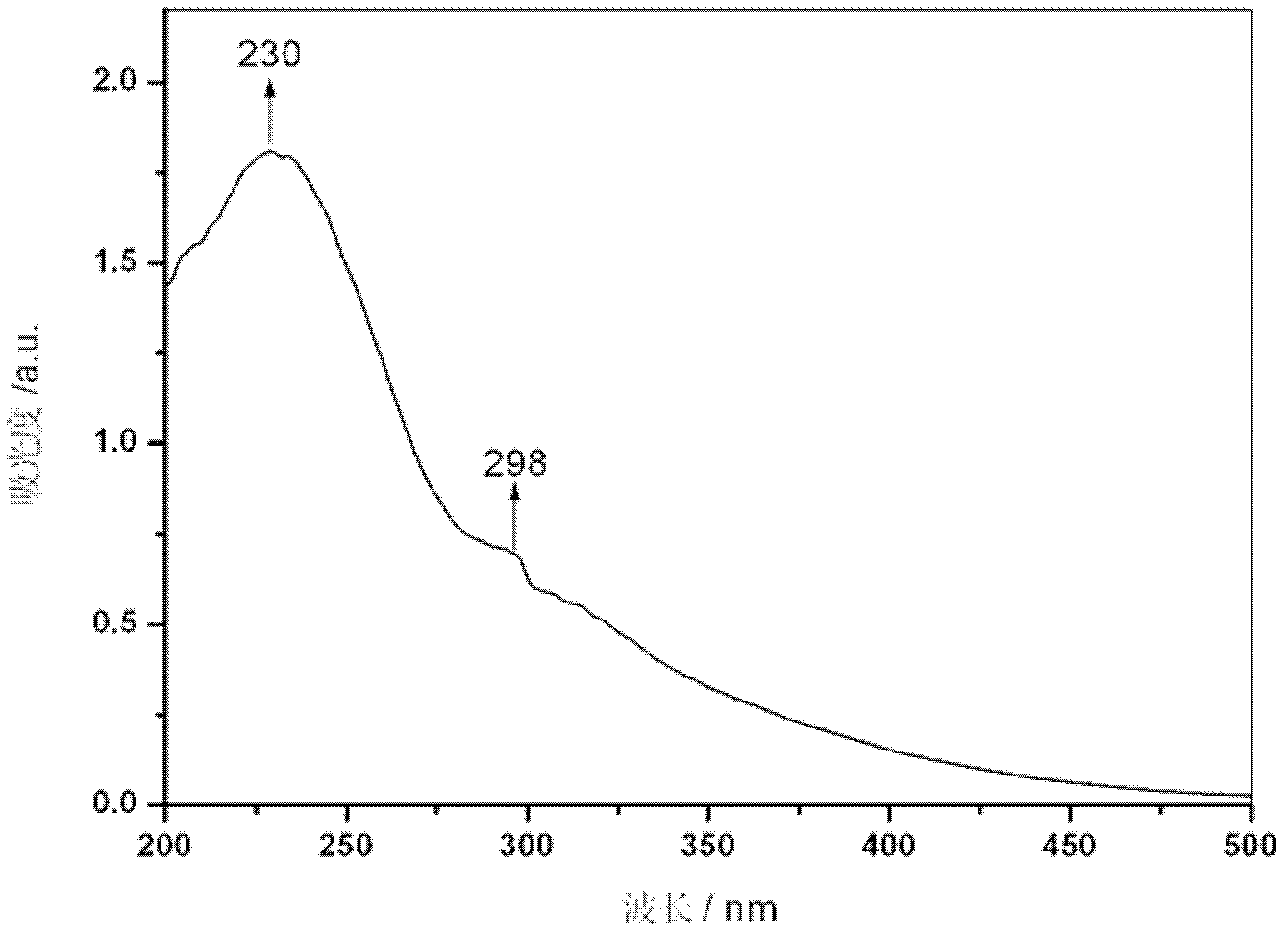

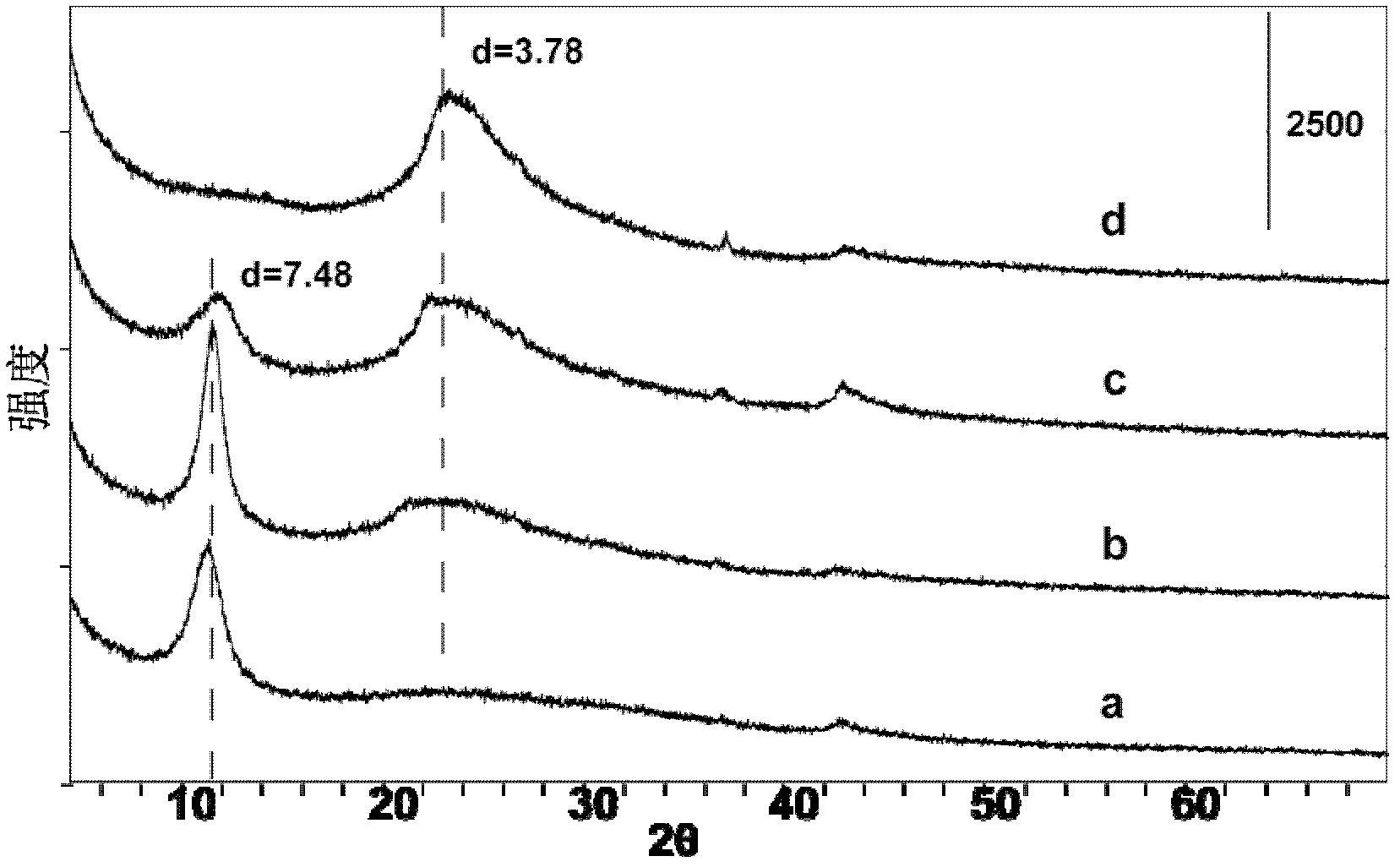

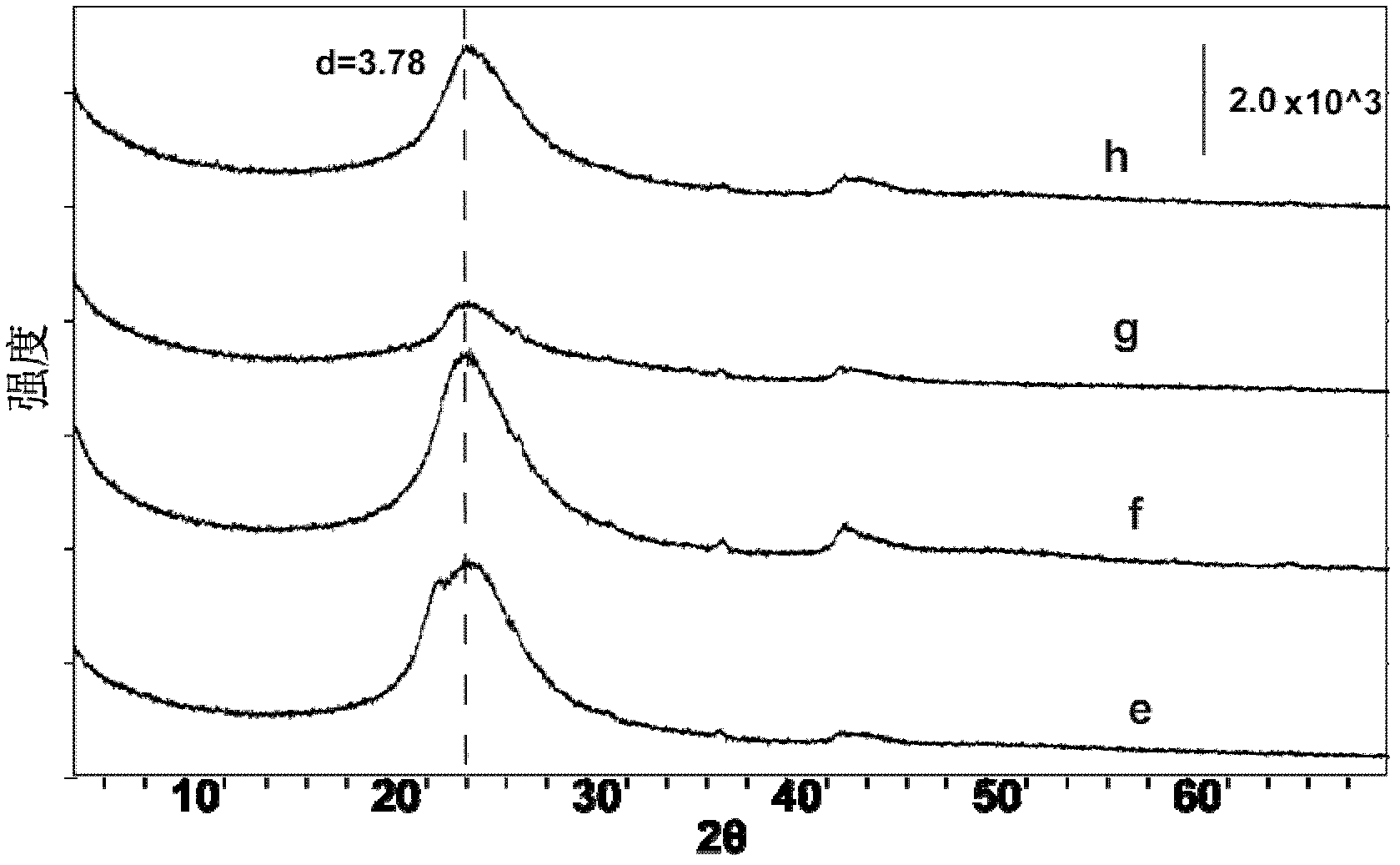

[0053] Use ultrasonic vibration to disperse 120mg graphite oxide in 150ml water, such as figure 1 Shown is the ultraviolet-visible spectrum of the graphite oxide soluti...

Embodiment 2

[0056] 1. Use ultrasonic vibration to disperse 120mg of graphite oxide in 120ml of water to obtain a colloid;

[0057] 2. Add 655 mg of zinc powder and 30 ml of 2.0 mol / L hydrochloric acid to the colloid obtained in step 1, and react at room temperature for 6 hours to end the reaction. The resulting mixture is filtered, washed with water, and dried to obtain graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com