Control method for stabilizing high-density carbon monoxide virgin gas transformation process

A control method and raw material gas technology, applied in chemical instruments and methods, climate sustainability, sustainable manufacturing/processing, etc., can solve problems such as high CO and water vapor in raw material gas, frequent catalyst replacement, and surplus catalyst loading , to achieve the effects of moderate process conditions, easy control of reaction depth and saving dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

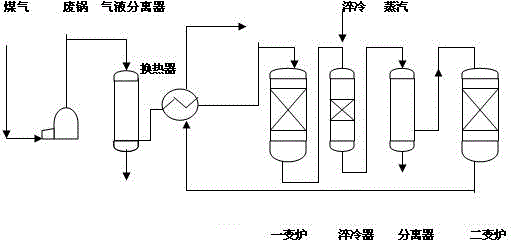

Embodiment 1

[0031] The crude gas with a CO dry basis content of 66% and a water vapor of 1.1 first enters the waste pot to reduce the water vapor to 0.40-0.70, then enters the gas-liquid separator to separate and remove excess water, and then enters the first reactor for conversion reaction. The water / gas volume ratio at the inlet of the first reactor is 0.40-0.70, the inlet temperature is 230-250°C, the reaction pressure is 3.1-3.8MPa, the hot spot temperature of the first reactor bed is 400-450°C, and the outlet gas The volume content of CO on a dry basis is 28-32%. The shift gas coming out of the first shift furnace exchanges heat with the raw material gas, then sprays water to cool down to 210°C-240°C and enters the second reactor to continue the shift reaction, the water / gas volume ratio is 0.2-0.4, and the inlet temperature is 210-240°C , the hot spot temperature of the second reactor bed is less than 430°C, and the volume content of dry basis CO at the outlet of the second reactor ...

Embodiment 2

[0033]The crude gas with a CO dry basis content of 48% and a water vapor of 1.4 first enters the waste pot to reduce the water vapor to 0.35-0.50. After entering the separator to separate and remove excess water, it enters the first reactor for shift reaction. The water / gas volume ratio at the inlet of the first reactor is 0.35-0.50, the inlet temperature is 230-270°C, the reaction pressure is 3.1-3.8MPa, and the hot spot temperature of the first reactor bed is less than 450°C. The volume content of dry basis CO in the outlet gas is 18-21%, which meets the requirements of methanol production.

Embodiment 3

[0035] The crude gas with a CO dry basis content of 60% and a moisture content of 0.16-0.25 directly enters the shift separator, detoxification tank and other equipment to remove impurities without adding steam, and then enters the first reactor for shift reaction. The first reaction The water / gas volume ratio at the inlet of the reactor is 0.16-0.25, the inlet temperature is 200-220°C, the reaction pressure is 3.1-3.8MPa, and the hot spot temperature of the first reactor bed is less than 440°C. The volume content of dry basis CO in the outlet gas is 36-42%. The shift gas with a dry basis content of CO of 36-42% exchanges heat with the feed gas, then sprays water to cool down to 220-230°C and enters the second reactor to continue the shift reaction. The water / gas volume ratio is 0.15-0.40, and the inlet temperature is 220-230°C, the hot spot temperature of the second reactor bed is less than 420°C, and the volume content of dry basis CO at the outlet of the second reactor is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com