Kiln waste heat utilization system

A waste heat and kiln technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of less frequency of plaster mold grouting per shift, wide distribution of grouting platform heating systems, and unreasonable layout of waste heat pipes, etc., to achieve Overcome the effects of unreasonable cooling, increased use times, and reduced heat intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

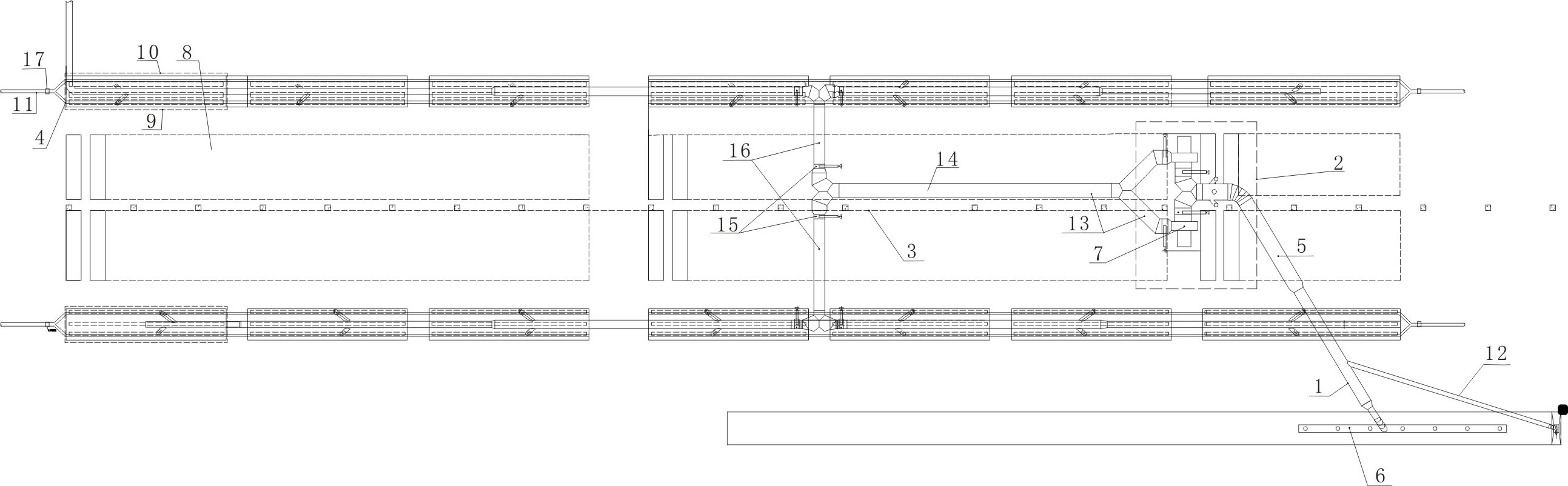

[0019] Such as figure 1 As shown, a kiln waste heat utilization system is composed of a remote heat extraction system 1, a mixing system 2, a conveying system 3 and a moisture removal system 4. One end of the air pipe 5 in the remote heat extraction system 1 is connected to the kiln waste heat extraction air The pipe 6 is connected, the other end of the air pipe 5 is connected with the mixing chamber of the mixing system 2, the mixing chamber is connected with the boiler induced draft fan 7, the air pipe of the mixing chamber is provided with a cold air gate, and the outlet pipe of the boiler induced draft fan 7 passes through the conveying system 3 The conveying pipeline communicates with a plurality of drying chambers. The drying chamber is divided into a mold drying chamber 9 close to the grouting area 8 and a billet drying chamber 10 outside the mold drying chamber 9. The drying chamber communicates with the dehumidification pipe 11 of the dehumidification system 4 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com