Device for desulfurizing flue gas by seawater through membrane absorption and its process

A desulfurization device and membrane absorption technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of uneven distribution of absorption liquid and flue gas, difficult to achieve engineering applications, and high operation and maintenance costs. The effect of high seawater utilization rate, stable desulfurization efficiency, strong resistance to flue gas SO2 concentration and flow shock capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

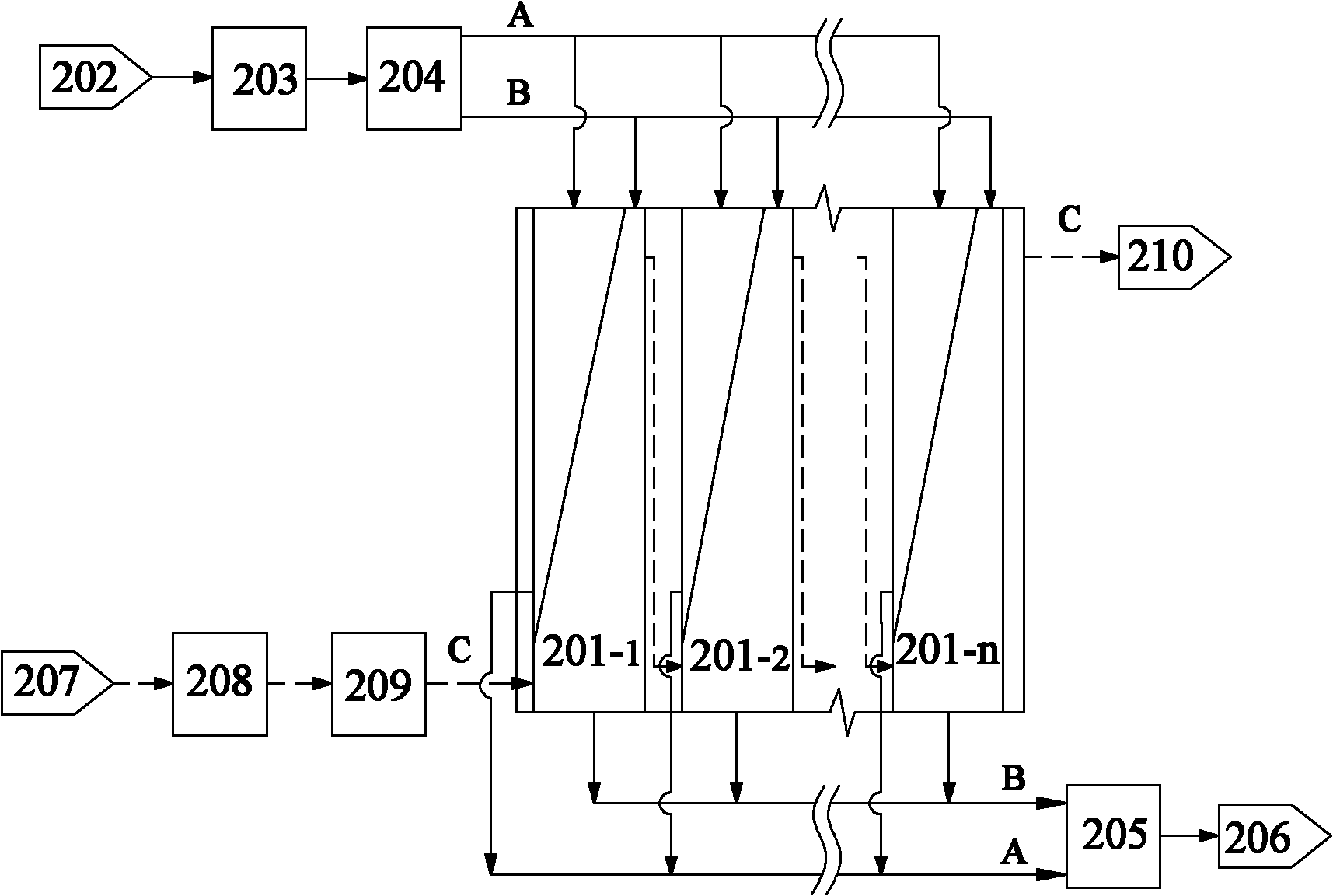

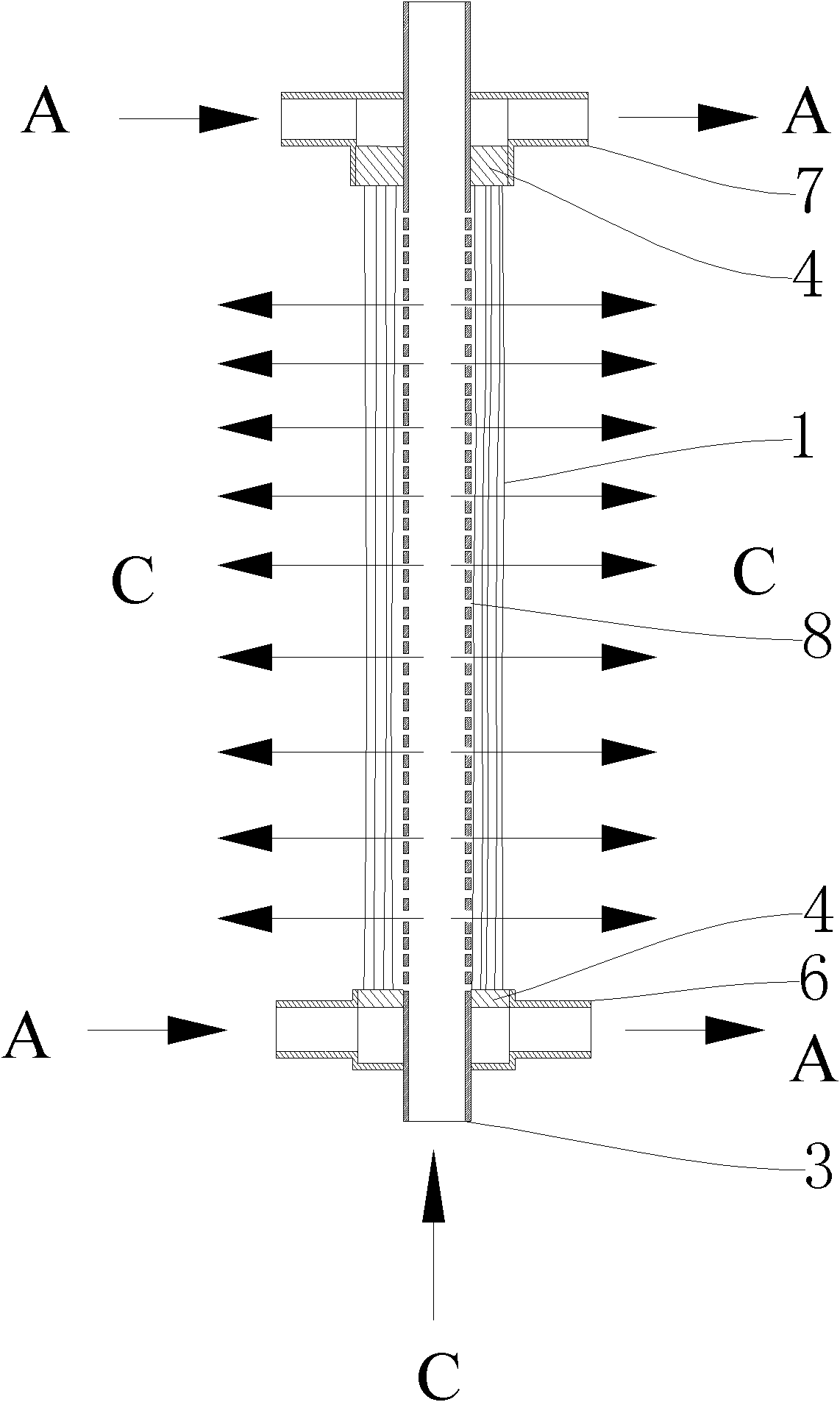

[0100] Use as figure 1 The membrane absorption method of seawater flue gas desulfurization process shown, the core part of the device desulfurization is composed of three levels such as Picture 11 The box-type gas-liquid contact membrane absorber shown is assembled in series and installed horizontally. The hollow fiber membrane filling area of each level of membrane absorber is 500m 2 , The membrane packing density is about 9%; raw seawater is used as the absorption liquid, the conductivity is 47400μS / cm~51800μS / cm, the pH value is 7.45~8.22, and the temperature is normal temperature; when the actual coal-fired flue gas is used, its SO 2 Concentration 1000mg / Nm 3 ~1600mg / Nm 3 , Smoke and dust concentration 100mg / Nm 3 , The temperature is 130℃~150℃, before entering the membrane absorber, it will be cooled to below 50℃ through the heat exchanger. Control the total flow of seawater 5m 3 / h~25m 3 / h, using parallel mode to flow through the 3-stage membrane absorber, seawater flows...

Embodiment 2

[0102] Using the same process, equipment and absorbing liquid as the above example 1, the flue gas is SO 2 The concentration is 2860mg / Nm 3 And 4290mg / Nm 3 High-concentration actual coal-fired flue gas, and control the seawater flow to 15m 3 / h, pH value is 8.20~8.51, flue gas treatment capacity is 500Nm 3 / h~1300Nm 3 / h, the corresponding concentration is 2860mg / Nm 3 The desulfurization rate is 97.7%~88.5%, the pH value of seawater after desulfurization is 3.3~5.5; the corresponding concentration is 4290mg / m 3 The flue gas, the flue gas treatment capacity ≤1000Nm 3 / h, the desulfurization rate is 97.1% to 90.6%, and the pH value of seawater after desulfurization is 2.7 to 5.0. Flue gas SO 2 The concentration is 1000mg / Nm 3 ~4290mg / Nm 3 Fluctuating within the range, flue gas processing volume≤1000Nm 3 / h, the desulfurization rate is above 90%. The membrane fouling control of the gas phase and the liquid phase, and the post-treatment of the cleaning seawater and the desulfurized s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Wall thickness range | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com