Soft Start Hermetic Compressor

A compressor and closed-type technology, applied in the direction of machines/engines, liquid fuel engines, mechanical equipment, etc., can solve the problems of reduced efficiency, low capacity, increased cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

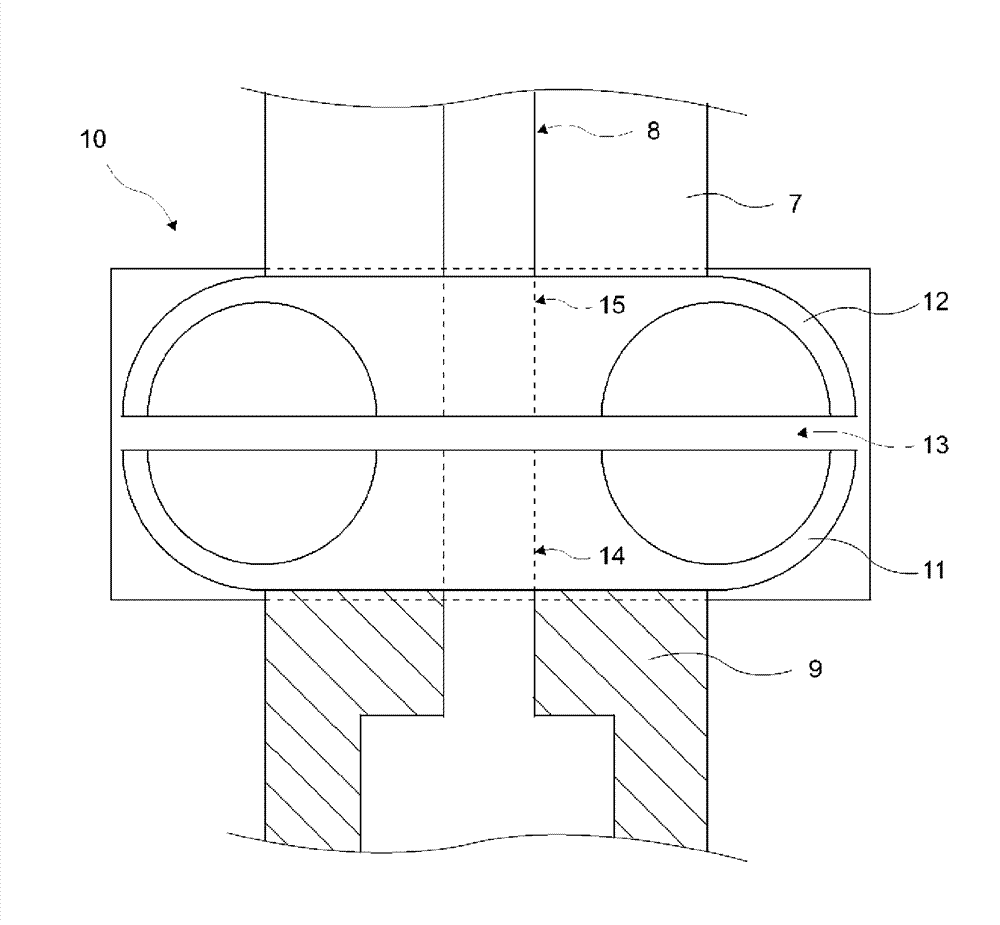

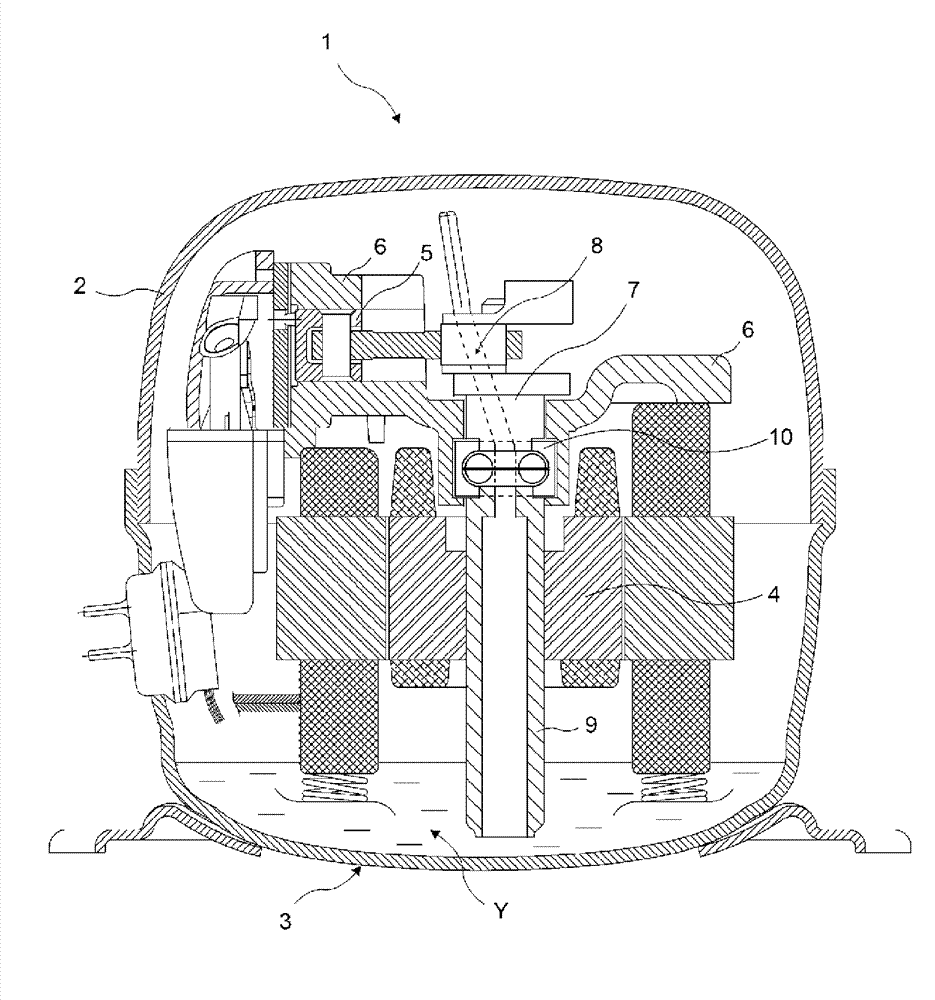

[0031] The hermetic compressor 1 comprises: a housing 2, in which the elements are carried; an oil sump 3, which forms the lower part of the housing 2 and in which is placed oil Y, which provides lubrication to the movable elements; an electric motor, which has a rotor 4 and stator; piston 5, which provides delivery of refrigerant fluid in a pressurized state to the refrigeration system; cylinder 6, which is arranged on the upper side of rotor 4, in which piston 5 operates; crankshaft 7, which is supported by cylinder 6 , which transmits the rotary motion of the rotor 4 to the piston 5 by converting it into a linear motion and includes a lubricating channel 8 which supplies oil Y to the movable elements contained in the housing 2 on the upper side of the rotor 4 and, the oil extraction pipe 9, which is installed on the rotor 4 by a press-fit assembly method, the lower end of the oil extraction pipe is submerged in the oil Y in the oil tank 3 and its upper end extends upward fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com