Trim winder for strip material

A technology of winding machine and edge material, which is applied in the direction of winding strip, thin material processing, transportation and packaging, etc., can solve the problems such as the inability to fully guarantee the mechanical stability and the inability to fully shorten the non-production time of the edge material package, etc. Achieving the effect that is beneficial to operational reliability and high operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

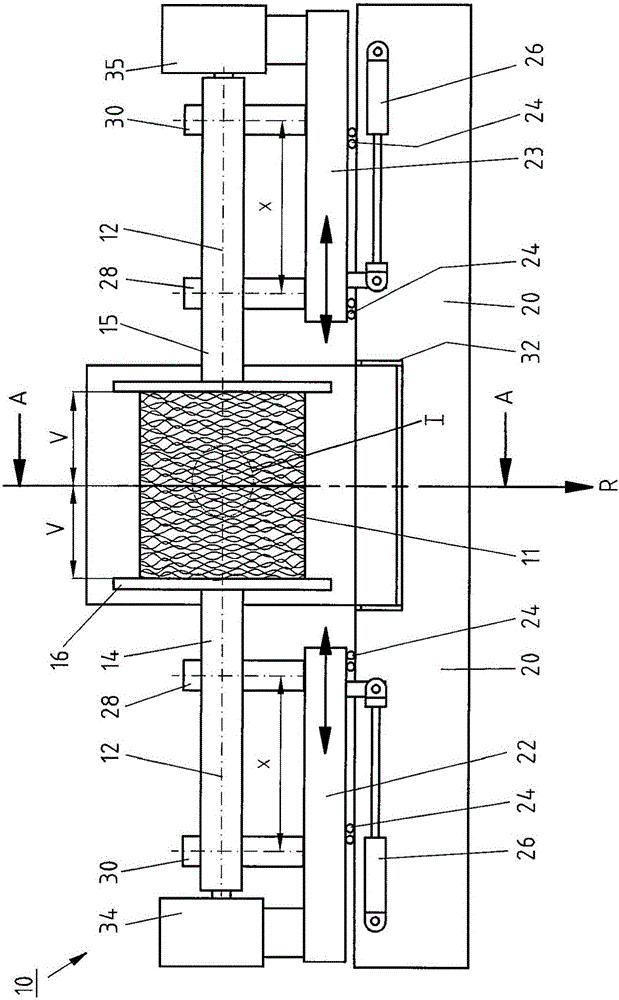

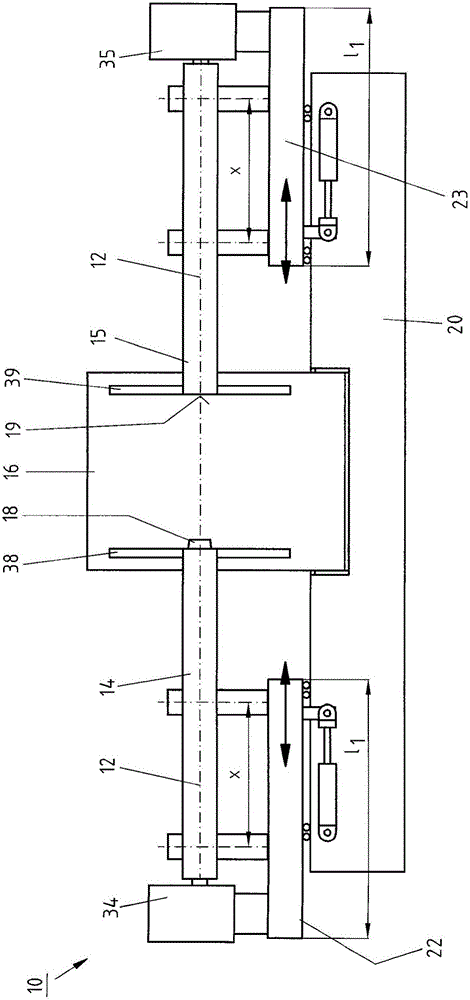

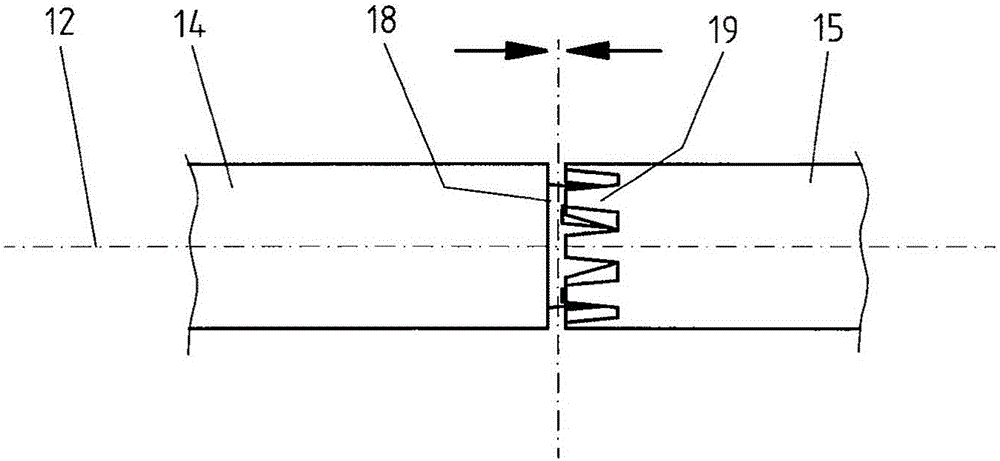

[0030] figure 1 A simplified side view of a trim winder 10 according to the invention is shown. The scrap winder 10 comprises two winding mandrels 14 , 15 mounted rotatably about its longitudinal axis 12 , which are arranged coaxially with one another along their longitudinal axis 12 and which can each be axially opposite each other. move with each other. Furthermore, the scrap winder 10 also comprises a winding section 16 , referred to below as a winding box, in which the respective free end sides 18 , 19 of the two winding mandrels 14 , 15 can be relatively.

[0031] The trim winder 10 has a base frame 20 . The base frame 20 is preferably constructed in one piece and accordingly has a superior stiffness for absorbing gravity and / or running forces. The winding mandrels 14 , 15 are each received supportively on a separate displaceable base 22 , 23 , wherein the displaceable bases 22 , 23 are displaceable via roller arrangements 24 relative to the base frame 20 axially in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com