High-wear-resistant driving wheel

A driving wheel, high wear-resistant technology, applied in the direction of belt/chain/gear, portable lifting device, working accessories, etc., can solve the problem of the joint of polyurethane and aviation aluminum falling off, affecting the efficiency and production capacity of square cutting machine, and cannot be recycled and reused and other problems, to achieve the effect of improving rigidity, increasing service life, and increasing the number of repeated uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples are used to illustrate the present invention, but are not used to limit the scope of the present invention, all equivalent technical solutions also belong to the category of the present invention, and the patent protection scope of the present invention should be defined by each claim.

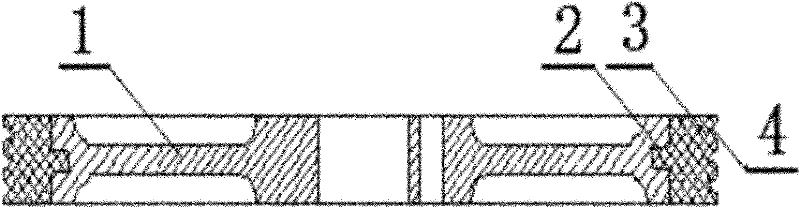

[0019] from figure 1 It can be seen from the figure that a high wear-resistant driving wheel includes an aluminum insert 1 made of 2A12 aviation aluminum, and a polyurethane layer 3 with a double-layer structure is injected on the aluminum insert 1, the inner layer is made of TPU359X, and the outer layer is made of TPU359X. The layer is made of TPUTK95A material. Several grooves 4 are formed on the circumference of the polyurethane layer 3 , and T-shaped grooves 2 are formed on the aluminum insert 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com