Rotation cage type automatic laying machine of solar cell serial slices

A solar cell, automatic laying technology, applied in circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of low accuracy and stability, large footprint, long assembly line distance, etc., to achieve smooth and stable process. The effect of safety, small footprint and short conveying distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

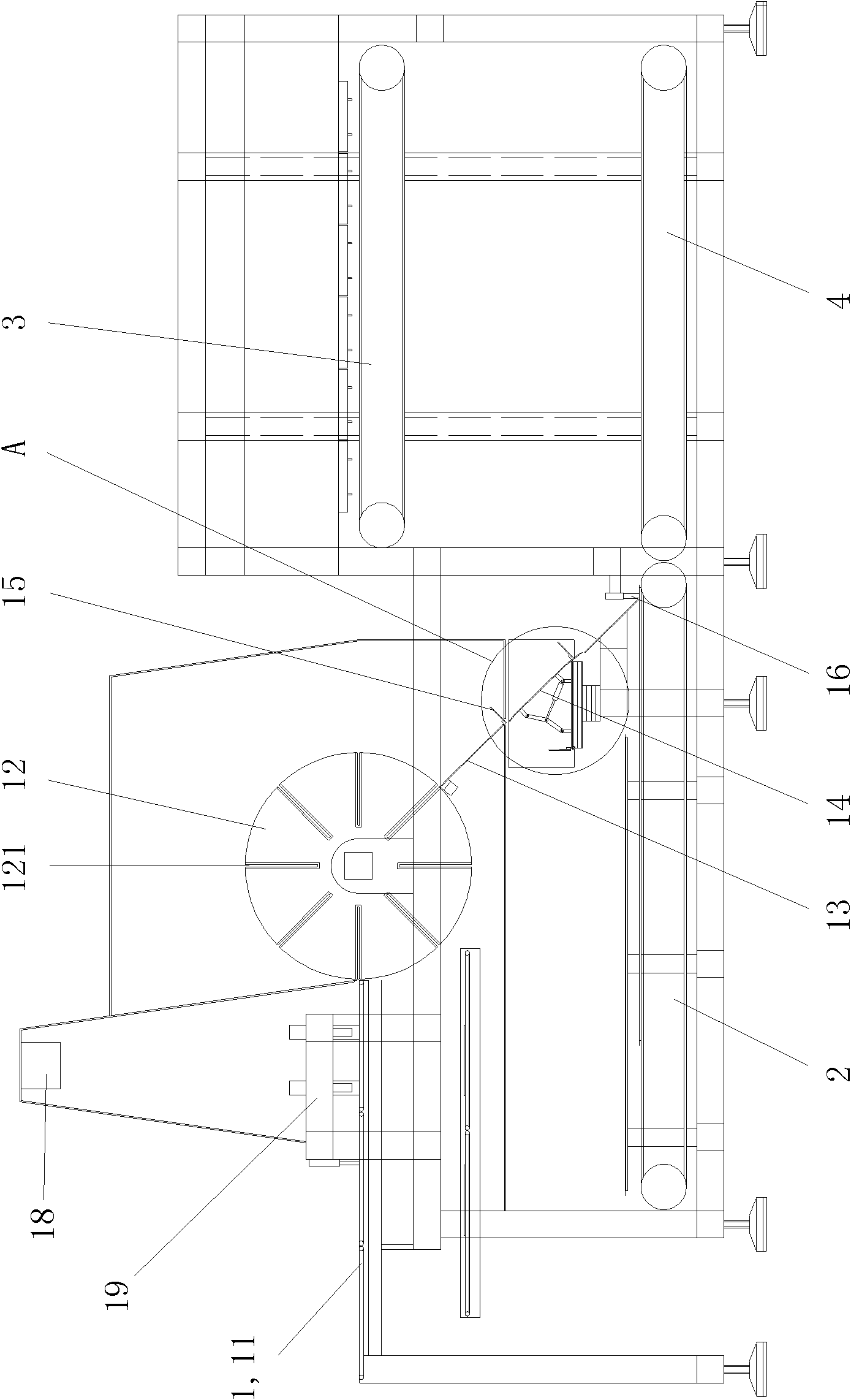

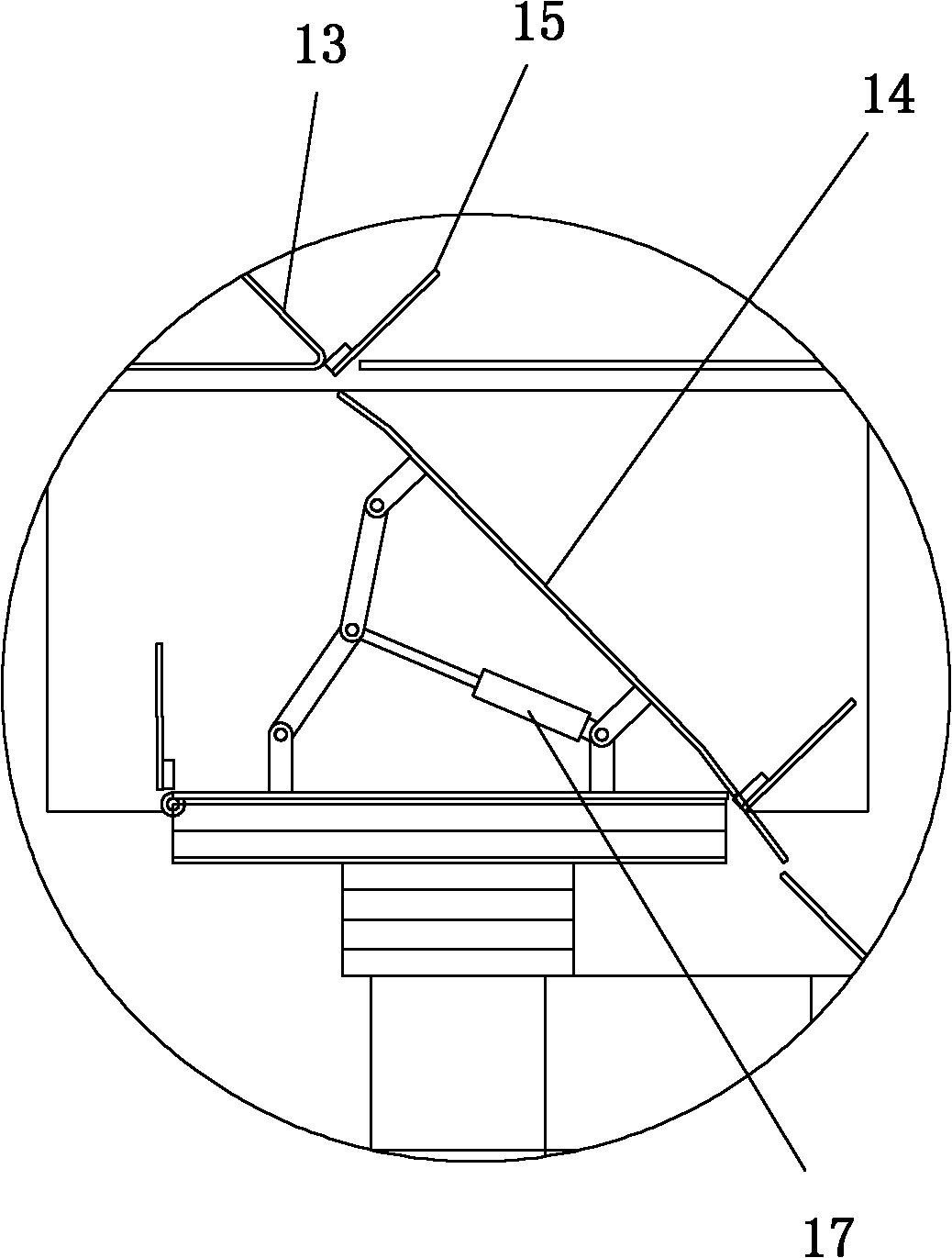

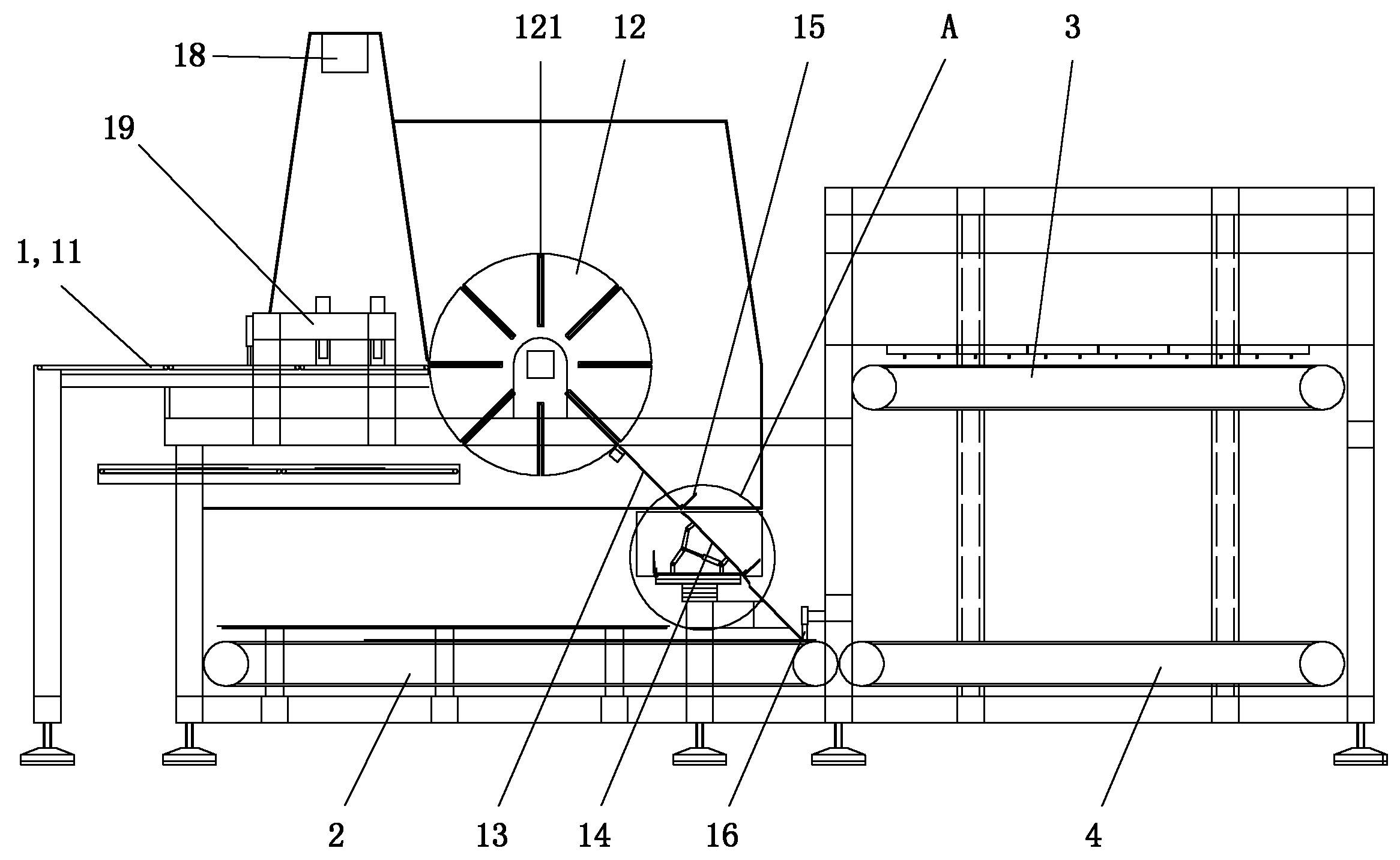

[0016] See figure 1 and figure 2 , the present invention has a battery string conveying system 1, an EVA glass substrate laying conveying system 2 and a confluence welding conveying system 3. A vertical conveying system 4 is provided between the systems 3; the battery string conveying system 1 includes a battery string conveying belt 11, a battery string flipping temporary storage cage 12, an inclined carriage 13 and a steering bracket 14, and the battery string conveying The belt 11 is provided with a longitudinal positioning device 18 and a longitudinal fixed-length cutting device 19. The longitudinal positioning device 18 is an infrared sensor. During the rotation of the battery string overturning temporary storage cage 12, the battery string temporary storage tank 121 can rotate cyclically to the first station docked with the battery string conveyor belt 11 and to the second station docked with the inclined carriage 13. Position; the battery string flip temporary storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com