Automatic billet receiving device and four-mold-opening grouting machine

An automatic and grouting technology, applied in conveyors, ceramic molding machines, mechanical conveyors, etc., can solve the problems of time-consuming and laborious, reducing the qualified rate of the green body, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

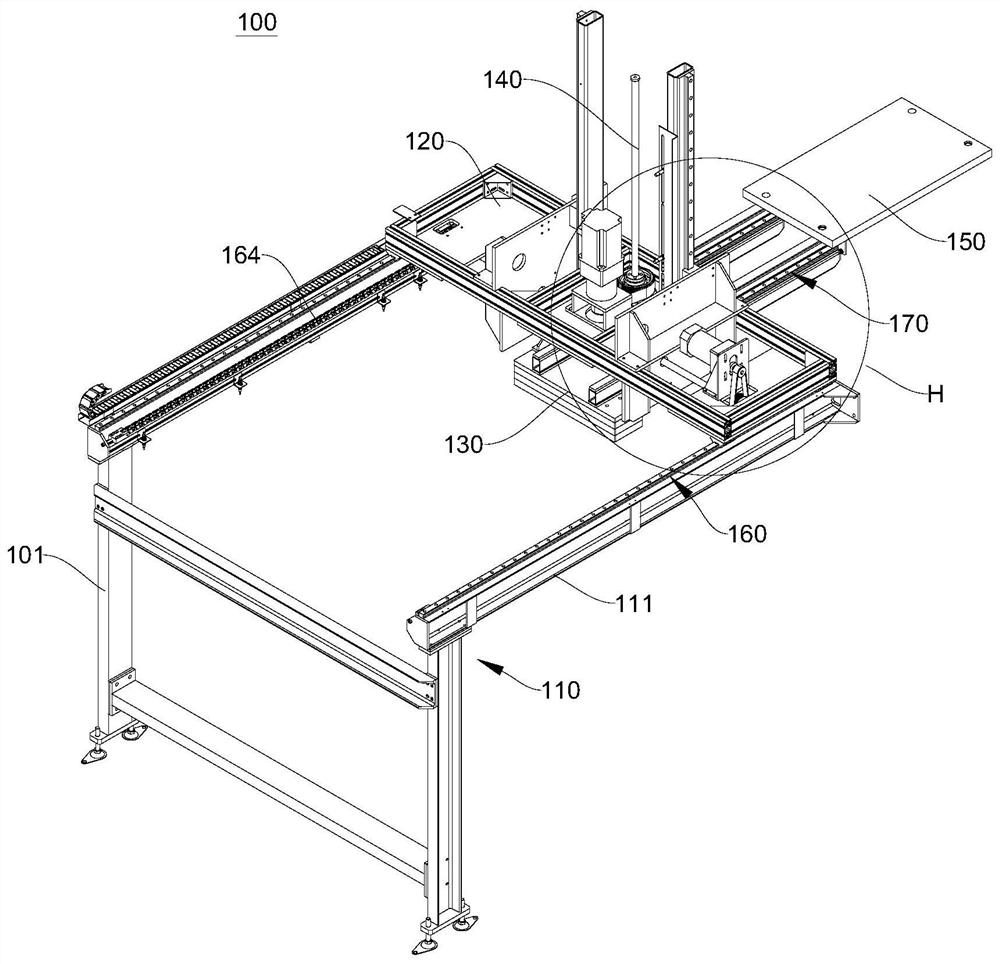

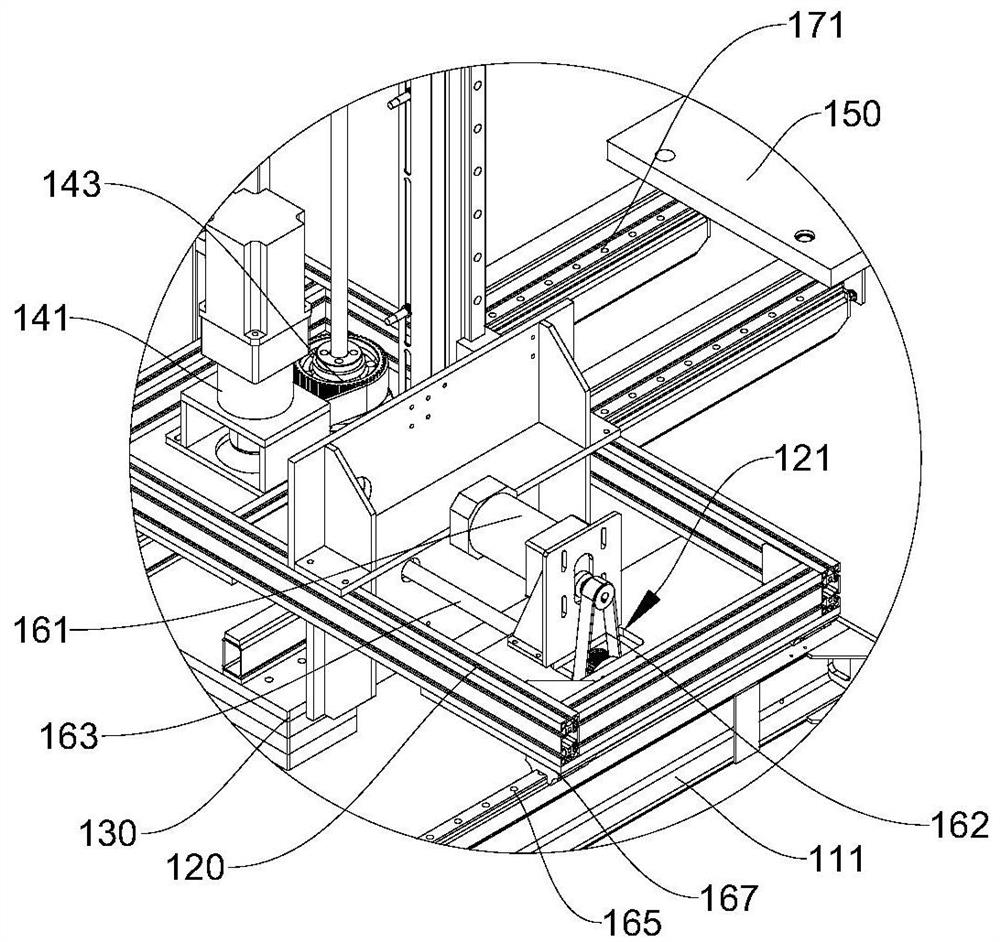

[0037] Please refer to figure 1 and figure 2 , the present embodiment provides an automatic billet joining device 100, which is mainly used for automatic billet joining of the toilet liner. Of course, it can also be applied in other fields to realize workpiece transfer and transportation. The automatic blank connecting device 100 includes a blank connecting frame assembly 110 , a trolley assembly 120 , a blank connecting support frame 130 , a lifting module 140 and a blank connecting plate 150 . The trolley assembly 120 is movably arranged on the blank receiving frame assembly 110, the blank receiving support frame 130 is fixed on the trolley assembly 120, the blank connecting plate 150 is movably arranged on the blank receiving support frame 130, and the lifting module 140 is connected to the blank receiving support frame 130. The support frame 130 is connected to drive the blank support frame 130 to rise or fall. The blank connecting support frame 130 is driven by the tro...

no. 2 example

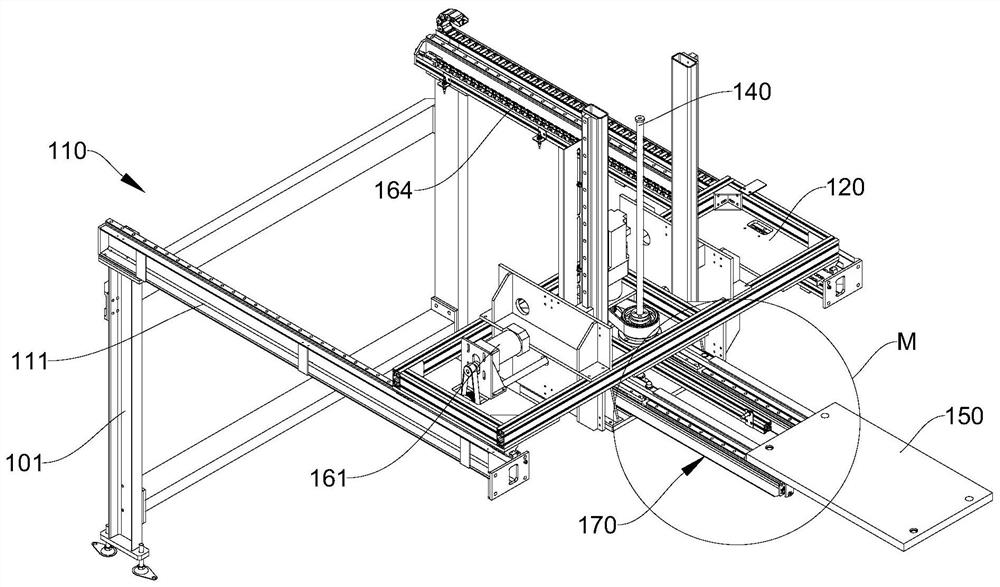

[0047] Please refer to Figure 5 and Figure 6 , and combined with figure 1 , a four-open mold grouting machine 300 provided in an embodiment of the present invention, including a grouting device 200 and an automatic billet connecting device 100 as described in any one of the preceding embodiments, the grouting device 200 is used for forming a green body , The automatic billet receiving device 100 is used to automatically take the billet, and realize the transfer and transportation of the billet. The four-mold grouting machine 300 integrates the grouting equipment 200 and the automatic billet receiving device 100, which can not only realize the molding of the green body, but also realize the automatic removal of the green body and the transfer of the green body, which greatly improves the production efficiency and quality.

[0048] The automatic blank connecting device 100 includes a blank connecting frame assembly 110 , a trolley assembly 120 , a blank connecting support fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com