Technological method for hydrogenation of coker full-range distillate

A process method and a whole-distillate technology, applied in the field of clean fuel production, can solve the problems of difficult operation, high investment, complex process flow, etc., and achieve the effects of flexible production plan, flexible production operation, and avoiding coking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

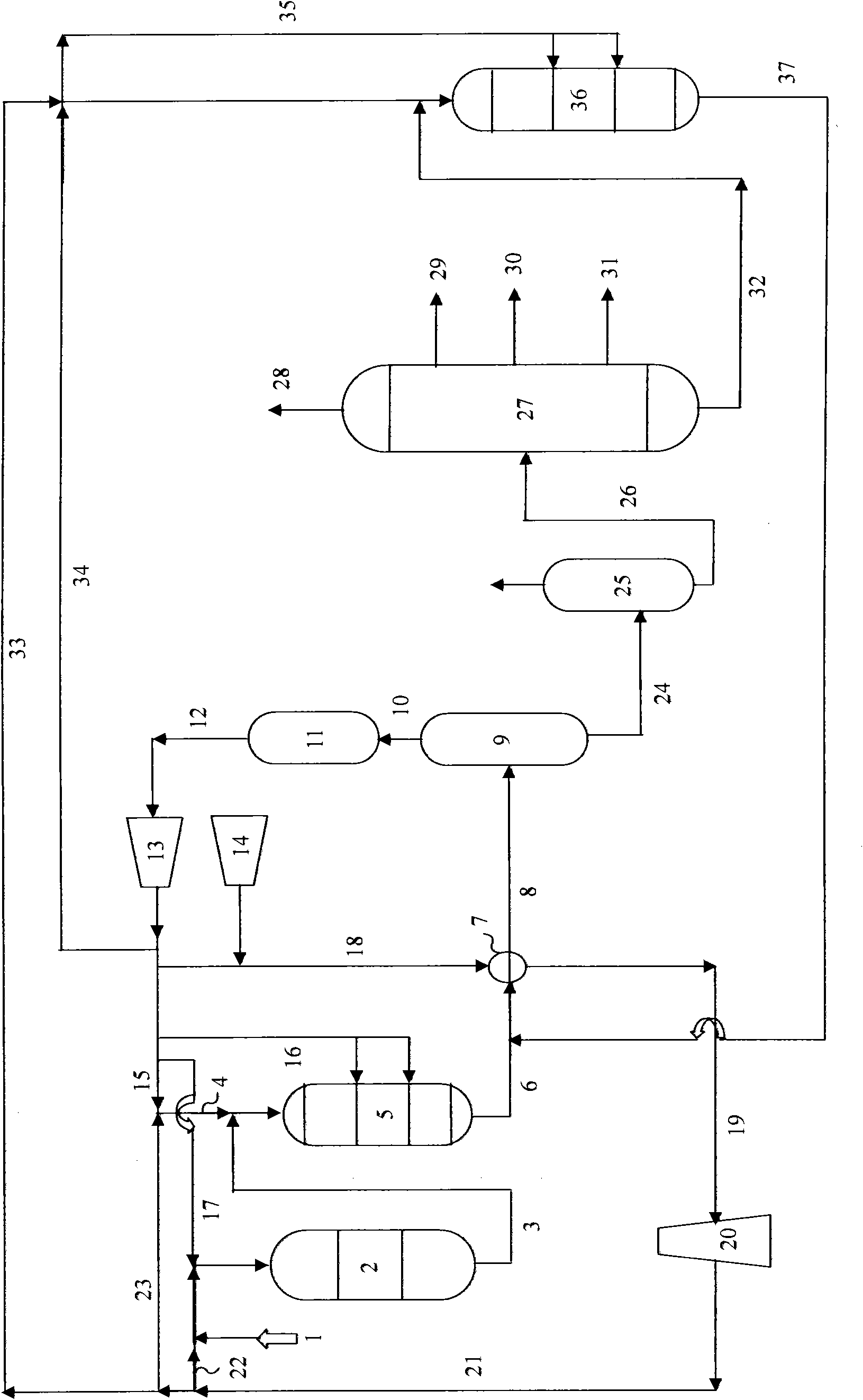

Method used

Image

Examples

Embodiment 1

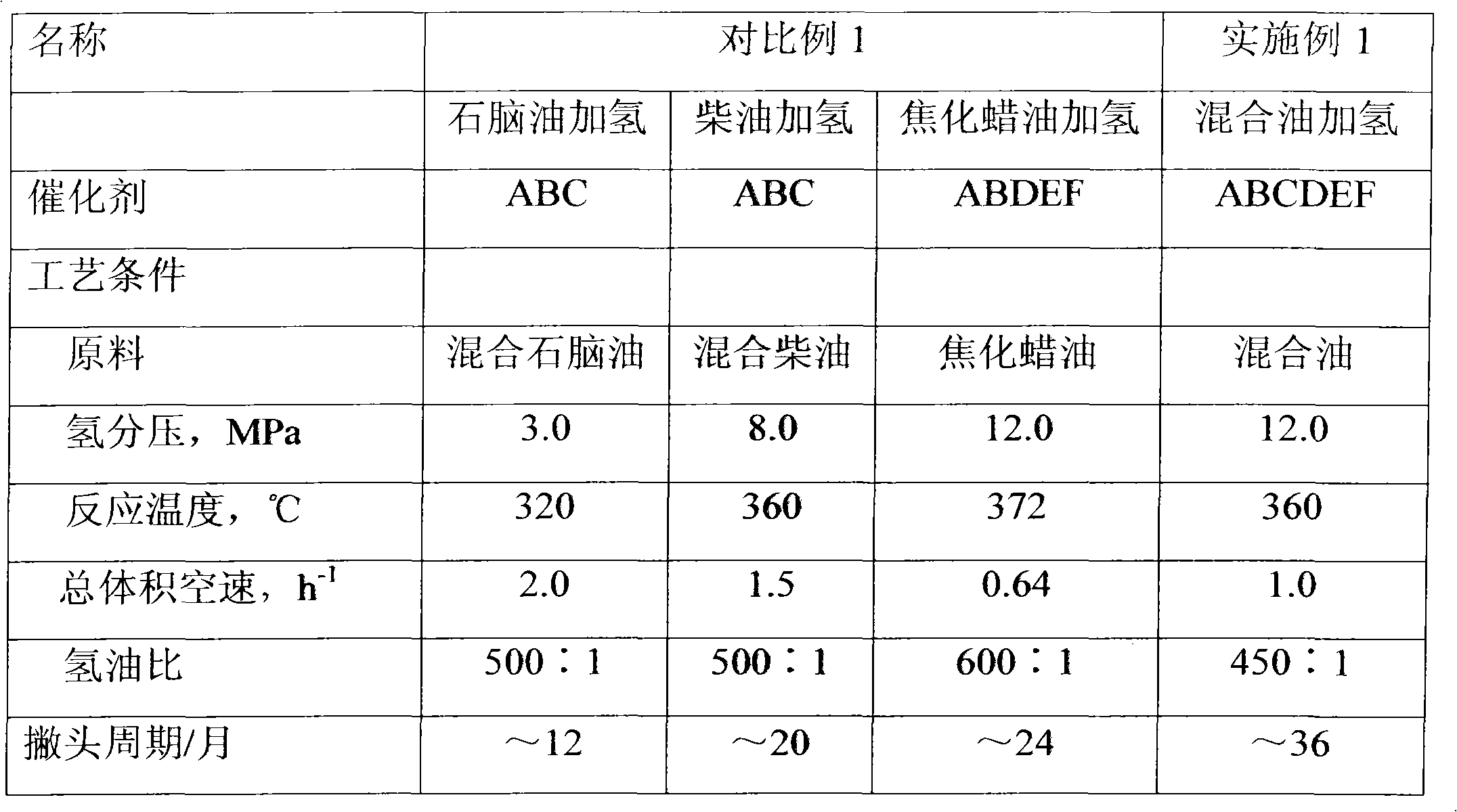

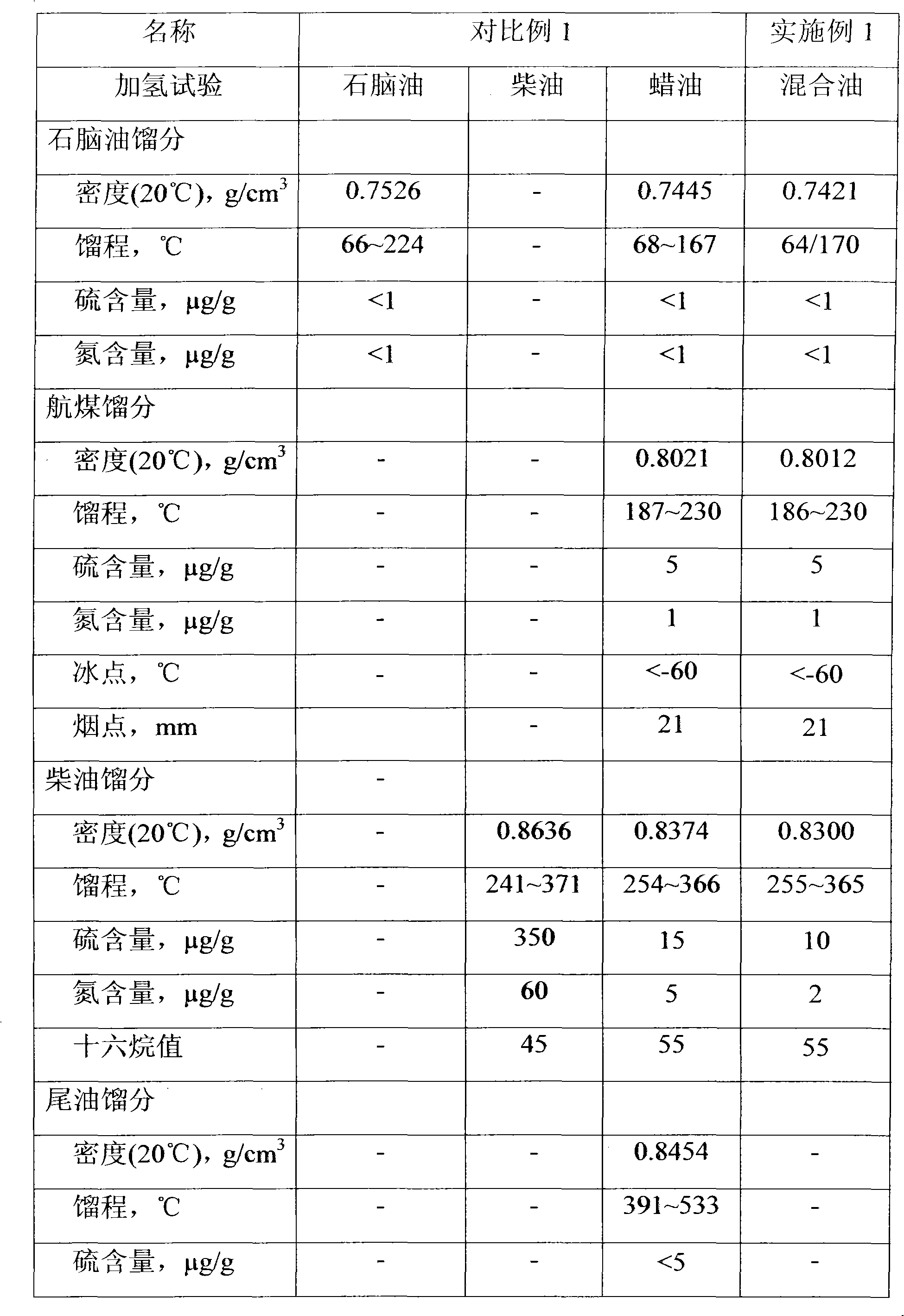

[0050] This embodiment adopts the method for hydrogenation and upgrading of coking gasoline and diesel fractions of the present invention, and Table 3, Table 4, and Table 5 respectively show the catalyst and process conditions, product distribution, and main product properties.

[0051] Table 1 Catalyst Physicochemical Properties

[0052] catalyst FZC-102B FHRS-1 FH-40C FF-14 FC-32 FH-98 Numbering A B C D E F Chemical composition, m%: MoO 3 5.2 3.5 4.5 24.2 - 9.2 WO 3 - 6.1 11.1 - 19.2 19.8 NiO 1.3 2.2 3.2 2.1 5.1 5.1 CoO - - - 1.7 - - Physical properties: Pore volume, mL / g ≮0.60 ≮0.50 ≮0.42 ≮0.59 ≮0.32 ≮0.25 Specific surface, m 2 / g ≮260 ≮300 ≮220 ≮280 ≮255 ≮120

[0053] Table 2 Raw Oil Properties

[0054] name coker naphtha Cok...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com