Barrel non-prebending rolling forming process

A technology of non-prebending rounding and forming technology, which is applied in the field of non-prebending rounding forming technology of cylinders, can solve the problems of increasing production costs of enterprises, achieve the effects of reducing production efficiency, improving process flow, and increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

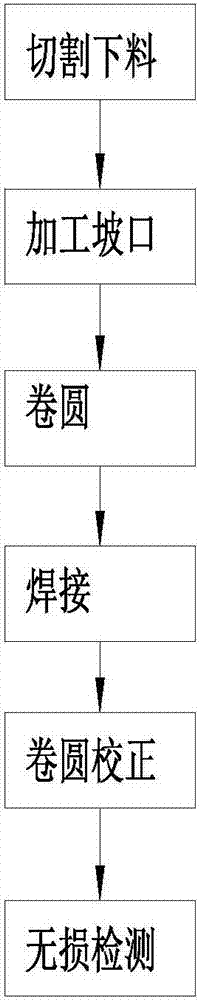

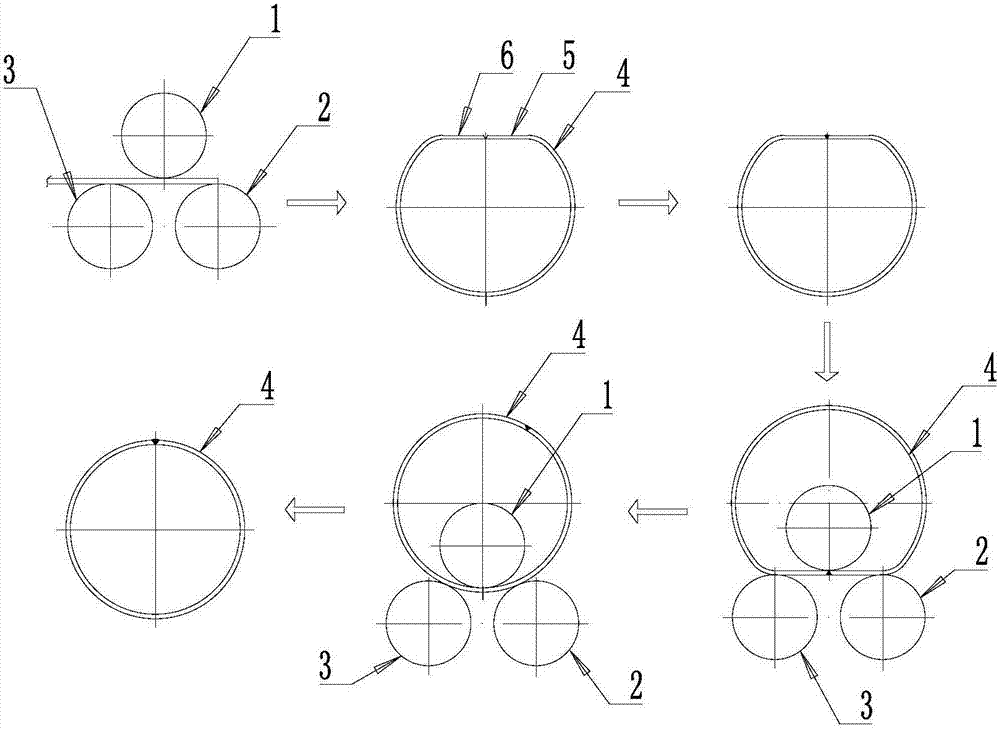

[0030] Such as Figure 1 ~ Figure 2 As shown, the cylindrical body of the present invention has no pre-bending round forming process, comprising the following steps:

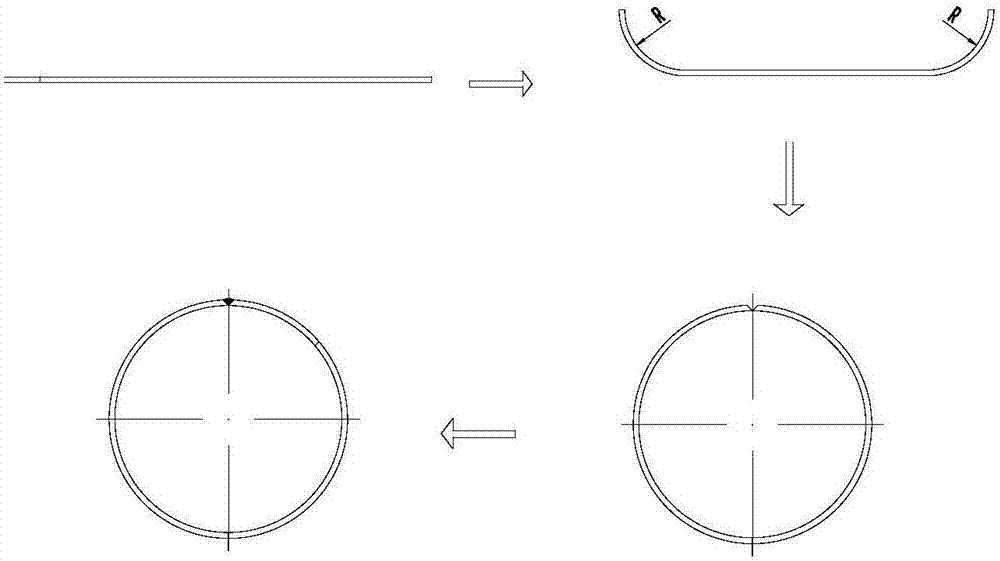

[0031] (1) Cutting and blanking: cutting and blanking of the plate according to the size required by the process;

[0032] (2) Rolling: Use a plate rolling machine to roll the cut plate in step (1);

[0033] (3) Welding: Weld the 4 side seams of the cylindrical shell formed in the step (2);

[0034] (4) Circle correction: use plate rolling machine to carry out circle correction to the cylindrical body (4) after step (3) processing;

Embodiment 2

[0036] Such as Figure 1 ~ Figure 2 As shown, step (1) and step (2) also includes step (a), processing the bevel, and processing the bevel of the plate cut in step (1). All the other are the same as embodiment one.

Embodiment 3

[0038] Such as Figure 1 ~ Figure 2 As shown, after step (4), step (b) of non-destructive testing is also included.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com