Special copying heat-transfer machine for ice hockey stick and hockey stick

A technology of hockey stick and thermal transfer printing machine, which is applied in rotary printing presses, printing presses, transfer printing and other directions, can solve the problems of low yield rate, low yield rate, easy generation of wrinkles, etc., and achieves efficient production methods and The effect of craftsmanship, smooth and smooth surface, and firm adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

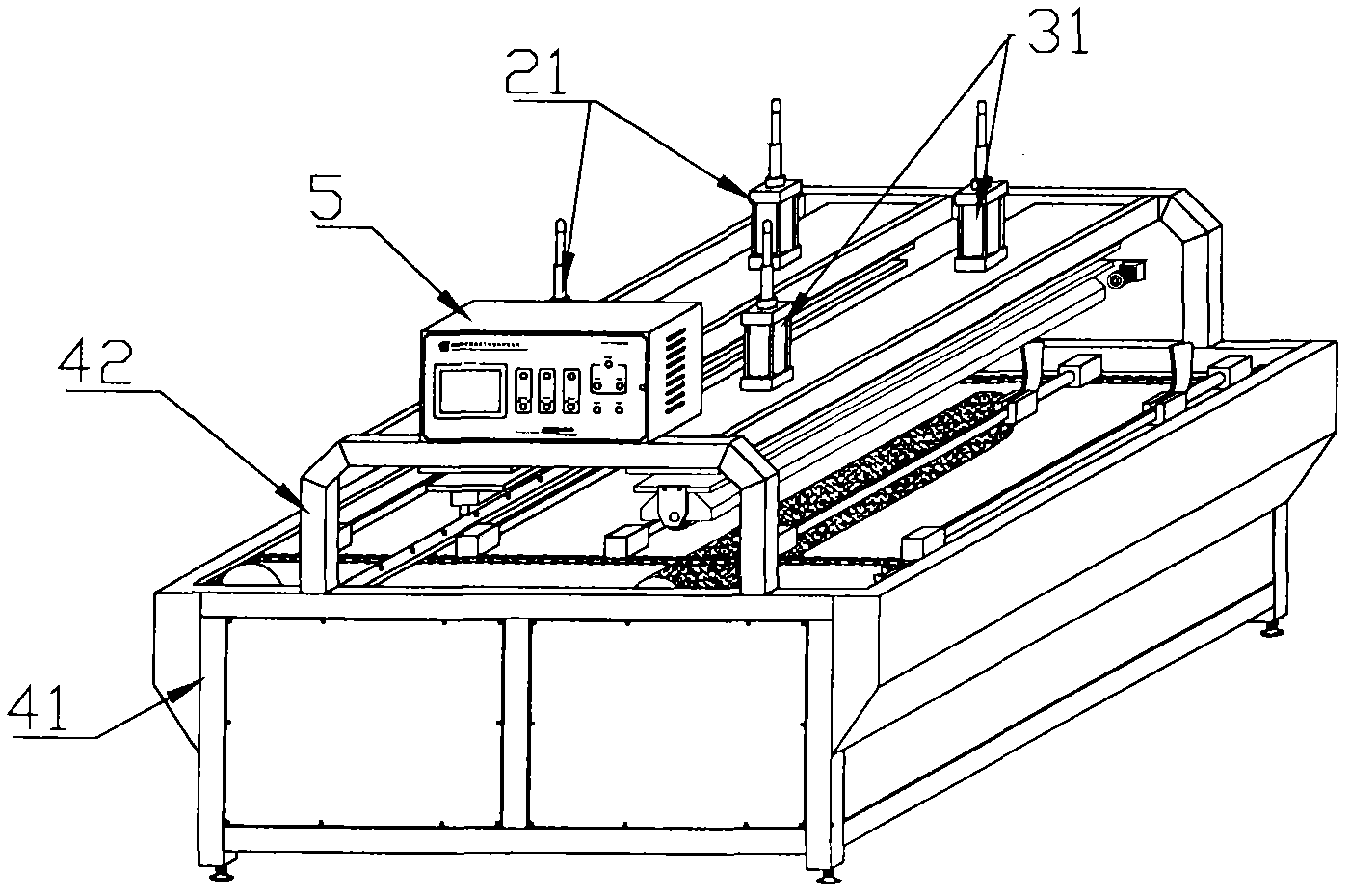

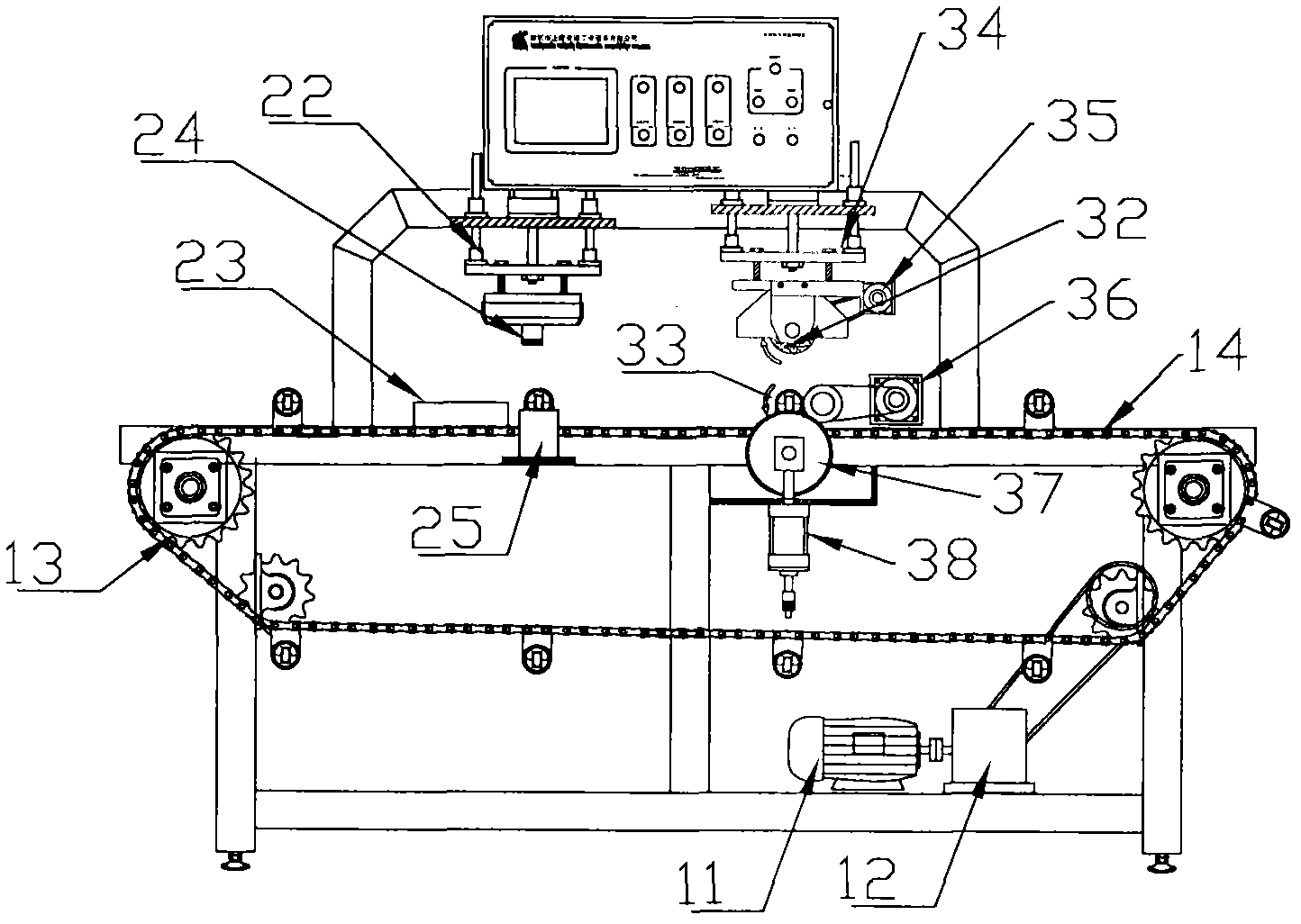

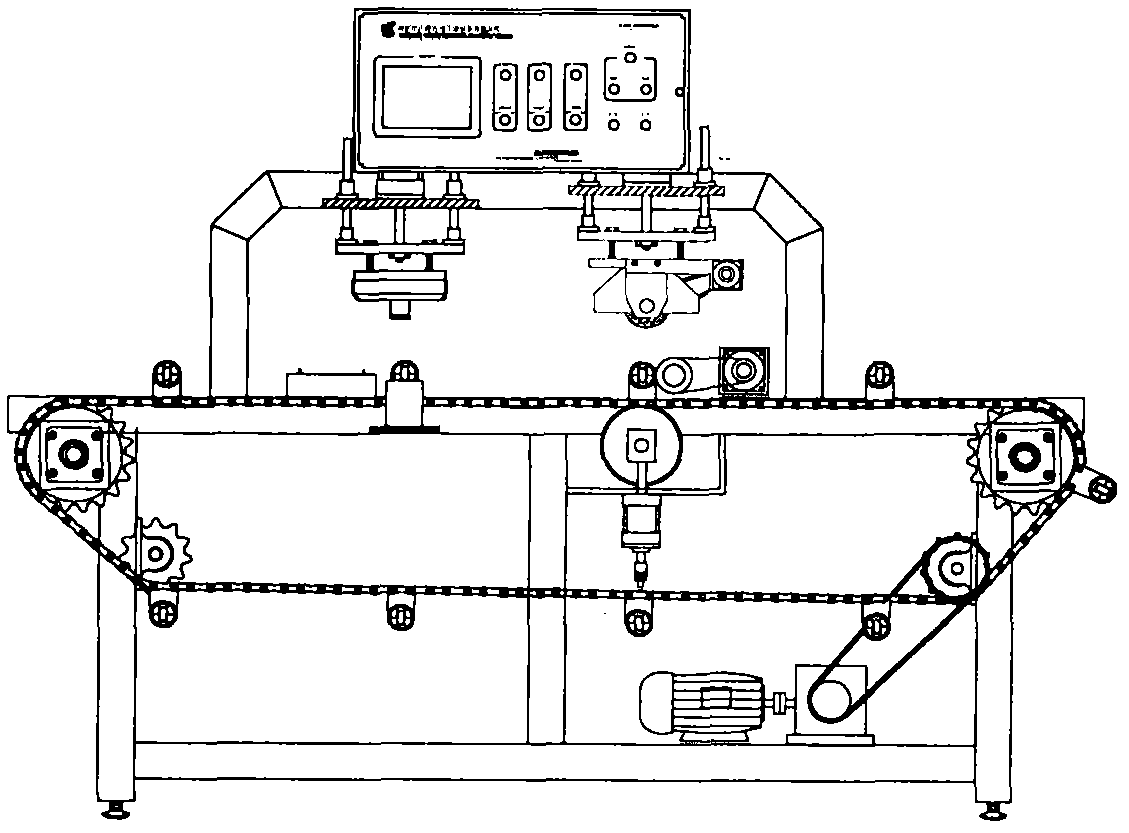

[0043] The heat transfer printing machine of the present invention includes a machine main frame for connecting, supporting and fixing various parts. The machine main frame is equipped with an electric and gas control system control electric box for the whole machine, and a transmission component is arranged on the machine main frame. , hot pressing film positioning flat pressing assembly, heat transfer printing assembly, the transfer assembly drives the cue to be processed through the hot pressing film positioning flat pressing assembly for hot pressing film positioning and thermal transfer printing through the thermal transfer printing assembly, and then transfers The components drive the processed clubs to be output as finished products.

[0044] like Figure 1-2 As shown, specifically in this embodiment, the transmission assembly includes a transmission motor 11 , a motor transmission device 12 , a transmission gear 13 , and a chain 14 or a conveyor belt installed on the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com