Catalyst for dimethyl ether preparation through methanol dehydration, its preparation method and application

A methanol dehydration and catalyst technology, which is applied in the dehydration of hydroxyl compounds to prepare ethers, ether preparations, molecular sieve catalysts, etc., can solve problems such as not emphasizing the role of molecular sieve pore structure, and achieve industrial production and application. The production process is simple and stable good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

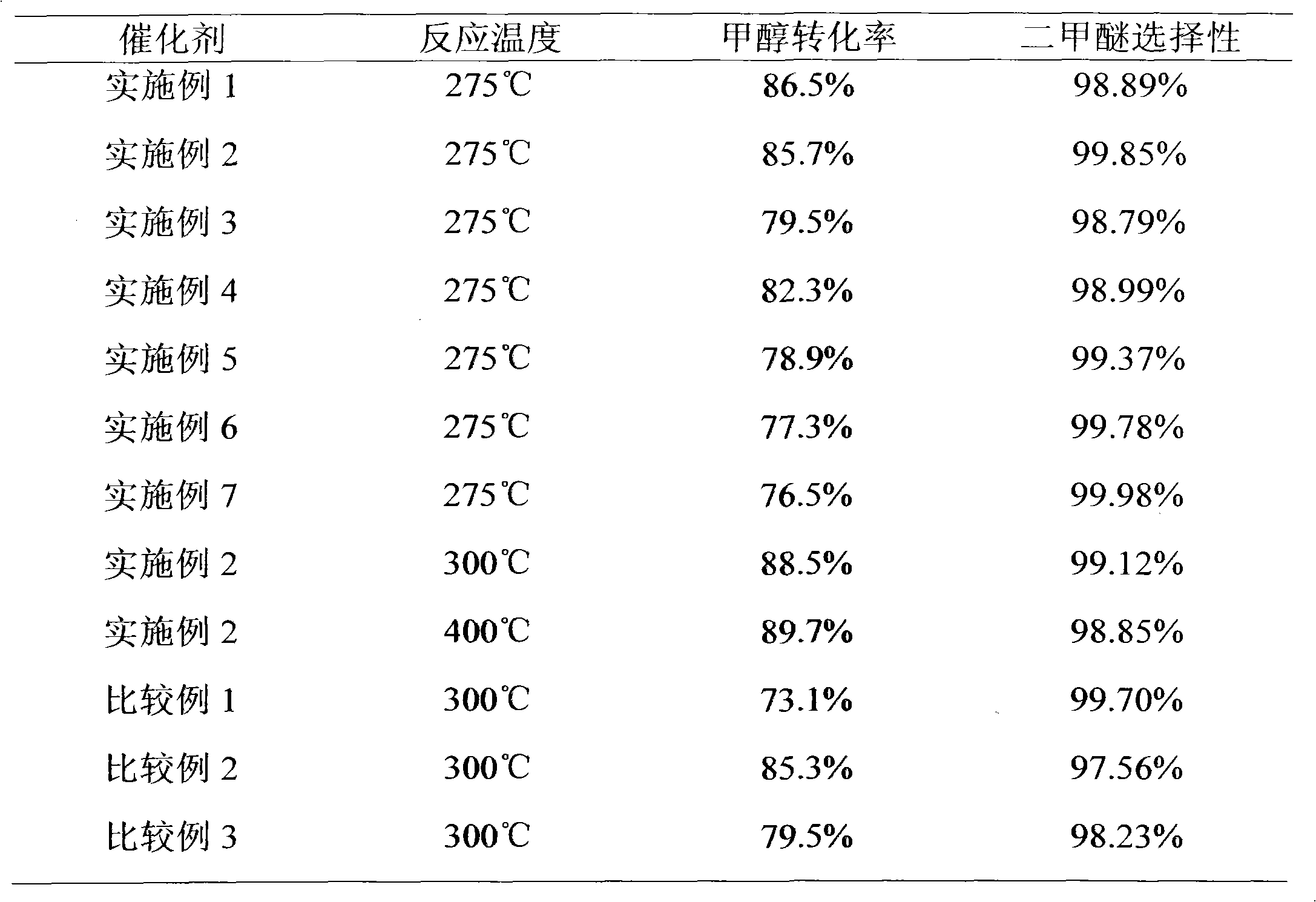

Examples

Embodiment 1

[0022] The first step: exchange 50g of Y-β composite molecular sieve with a relative content of 50% of the β zeolite component with 1.0L of ammonium nitrate salt solution with a concentration of 1.0mol / L for 3.0h under the condition of a constant temperature water bath at 80°C to make an ammonium type Y-β composite molecular sieve. Then wash, dry, and repeat the above process. Then the ammonium type Y-β composite molecular sieve after two exchanges was calcined at 550° C. for 4 hours in an air atmosphere. Then the ammonium type Y-β composite molecular sieve after being burned repeats the above-mentioned ammonium solution exchange process, and then is washed, dried, and then roasted at 550° C. for 4 hours in an air atmosphere. A hydrogen-type Y-β composite molecular sieve is prepared.

[0023] The second step: the obtained hydrogen-type Y-β composite molecular sieve, silicon dioxide, sage powder and water are mixed and kneaded, and extruded into a strip-shaped catalyst of 1.5...

Embodiment 2

[0026] Implementation process is except following difference, and all the other are all the same with embodiment 1:

[0027] In the first step, the temperature of the constant temperature water area is 75° C., and the concentration of the ammonium nitrate solution is 1.5 mol / L.

[0028] In the second step, the weight ratio of Y-β composite molecular sieve to binder is 80%:20% on a dry basis to obtain a catalyst product.

Embodiment 3

[0030] Implementation process is except following difference, and all the other are all the same with embodiment 1:

[0031] In the first step, the concentration of the ammonium nitrate solution is 1.5mol / L, the exchange time is 3.0h, and the temperature of the two times of burning is 600°C.

[0032] In the second step, the dry basis weight ratio of Y-β composite molecular sieve to binder is 50%:50%, and the catalyst product is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com