Sulfur-tolerant methanation catalyst and its preparation method

A technology for sulfur-resistant methanation and catalyst, which is applied in the field of sulfur-resistant methanation catalyst and its preparation, and can solve the problems of low methane selectivity and low CO conversion rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The second aspect of the present invention is the preparation method of the sulfur-tolerant methanation catalyst described in the first aspect of the present invention, which generally includes a co-impregnation step, a drying step and a calcination step. Specifically, step a is to prepare an impregnation solution, the solution contains molybdenum precursors and cobalt precursors, and at least one of zirconium precursors, cerium precursors or lanthanum precursors. Since this solution is used to impregnate the support, it is called an impregnation solution. Wherein, the solvent is water, the molybdenum precursor is a water-soluble molybdate, the cobalt precursor is a water-soluble cobalt salt, and the zirconium precursor is a water-soluble zirconium salt or a water-soluble zirconate or zirconate, The cerium precursor is a water-soluble cerium salt, and the lanthanum precursor is a water-soluble lanthanum salt.

[0033]Wherein the water-soluble molybdate is selected from...

Embodiment 1

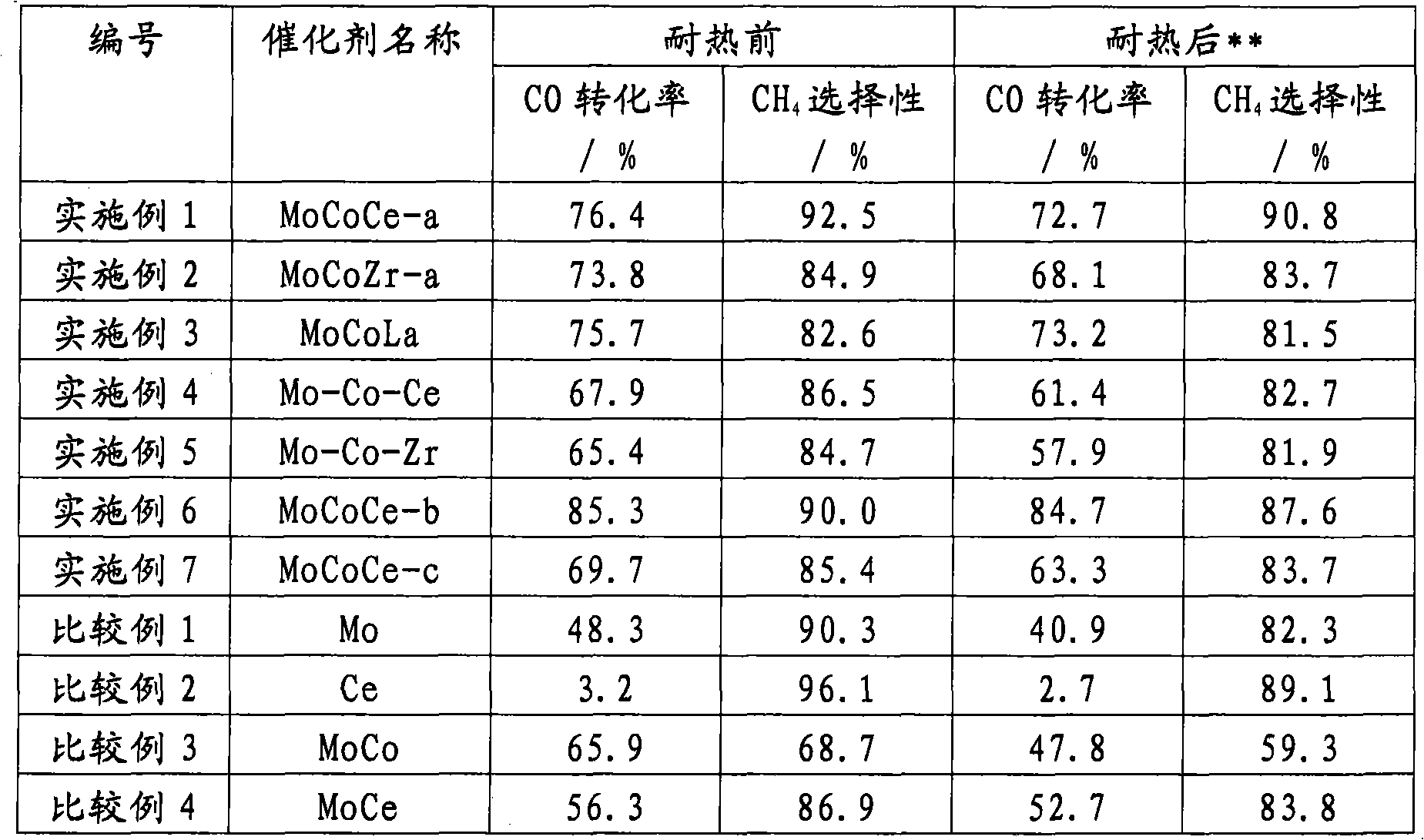

[0054] Weigh 18.42g (NH 4 ) 6 Mo 7 o 24 4H 2 O, 9.67g Co(NO 3 ) 2 ·6H 2 O, 5.06gCe(NO 3 ) 3 ·6H 2 O was dissolved in 60mL of high-purity water, and N-diethanolamine complex stabilizer was added. 100g Al 2 o 3 (The Al 2 o 3 γ-Al 2 o 3 , its physical properties are as follows: specific surface area ≥ 200m2 / g, pore volume ≥ 0.40mL / g, water absorption ≥ 52%, bulk density 0.65-0.72g / mL, crushing strength ≥ 80N / grain, particle size 3- 5mm, the same below) was put into the prepared mixed impregnation solution, left overnight, dried naturally, then dried at 120°C for 8h, and finally calcined at 450°C for 3h to obtain the MoCoCe-a catalyst. Take 5mL catalyst for evaluation test, the results of catalyst activity evaluation and heat resistance evaluation experiment are shown in Table 1.

Embodiment 2

[0056] Weigh 18.42g (NH 4 ) 6 Mo 7 o 24 4H 2 O, 9.67g Co(NO 3 ) 2 ·6H 2 O, 5.26g ZrOCl 2 ·8H 2 O was dissolved in 60mL high-purity water, and citric acid complex stabilizer was added. 100gAl 2 o 3 Put it into the prepared mixed impregnation solution, let it stand overnight, dry it naturally, then dry it at 120°C for 8 hours, and finally calcinate it at 450°C for 3 hours to obtain the MoCoZr-a catalyst. Take 5mL catalyst for evaluation test, the results of catalyst activity evaluation and heat resistance evaluation experiment are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com