Uvv curable coating compositions and method for coating flooring and other substrates with same

A composition and substrate technology, applied in polyether coatings, epoxy resin coatings, coatings, etc., can solve the problems of curing, inability to obtain the advantages of UVVLED, and achieve the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 24

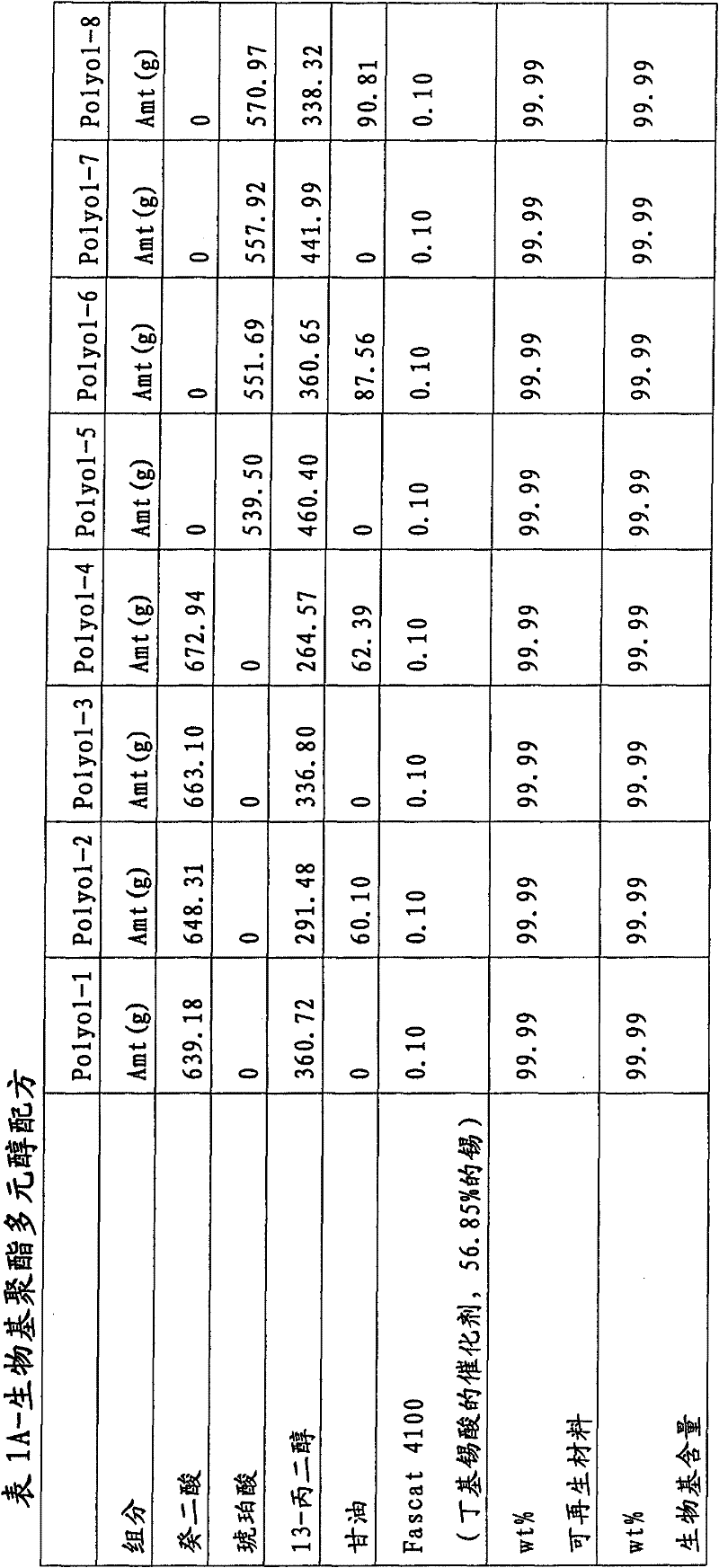

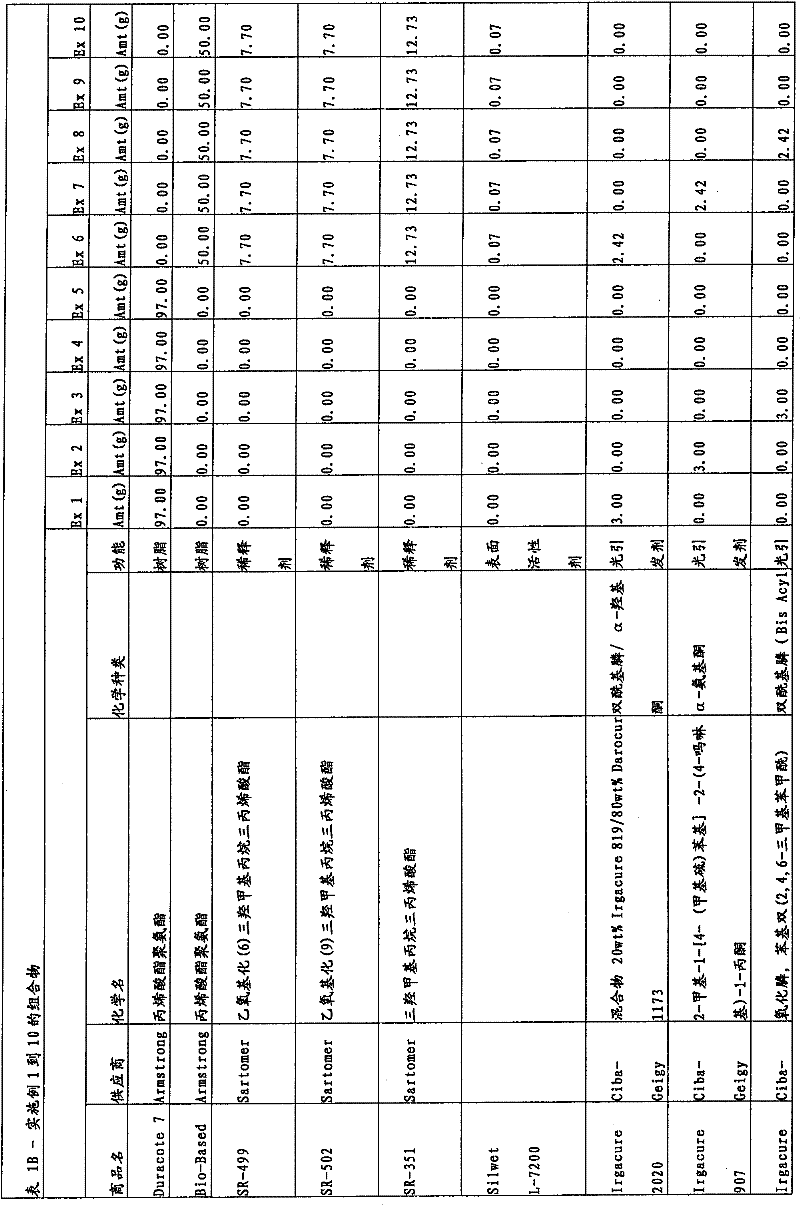

[0058] As the coating composition to be cured according to the exemplary embodiment, formulation compositions shown in Tables 1B, 2A, and 2B were prepared and cured using UVV LEDs using urethane acrylate as a resin. For each case, all qualified components were added to small brown glass jars and mixed with high speed agitation until the photoinitiator was dissolved. Examples 1 to 5 and 11 to 24 were mixed at 130°F, while Examples 6 to 10 were mixed at room temperature. Compounds identified in the table as "Duracote 7" refer to acrylate urethanes of the type disclosed in US Patent No. 5,719,227, which is incorporated herein by reference. The "bio-based acrylate polyurethane" resin is similar to Duracote 7, except that it is based on a castor oil polyol starting material, as described in US Publication No. 2009 / 0275674, which is also incorporated herein by reference.

[0059]

[0060]

[0061]

[0062]

[0063] After the photoinitiator was dissolved, the viscosity o...

Embodiment 25 to 31

[0084] The formulations shown in Table 6, prepared as coating compositions and cured using UVV LEDs, include Examples 30 and 31, which demonstrate green embodiments where the compositions are bio-based polyol crosslinkable compounds (Table Polyol-5) in 1A, used in combination with epoxy resin. For each case, all qualified components were added to a small brown glass jar and mixed with high speed agitation at 130°F until the photoinitiator was dissolved. At this point, add matting agent slowly and stir at high rpm for at least 15 minutes. Thereafter, the viscosity of the sample was measured.

[0085]

[0086]

[0087] Examples 25 to 31 were also applied to the same type of biobased tile as previously described, which was 1 mil thick, and was likewise cured using a Phoseon Technology WCRX Starfire LED Quad, which had a specific wavelength of 380 to 420 nanometers, using 2W / cm 2 Water-cooled UVV LED, the unit curing area is 0.75 inches by 12 inches. The height of the LE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com