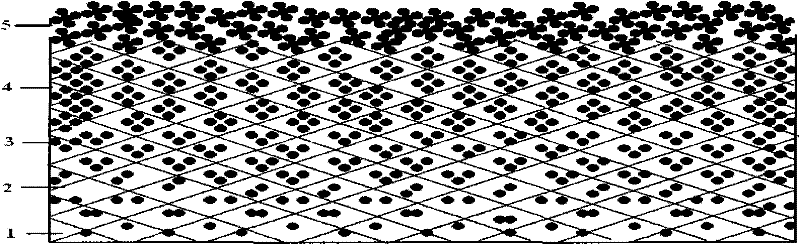

Gas diffusion layer with gradient hole structure and preparation and applications thereof

A gas diffusion layer and gradient hole technology, which is applied to the components of fuel cells, etc., can solve problems such as water shortage in the cathode, and achieve the effects of reducing body resistance, easy control, and increasing conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

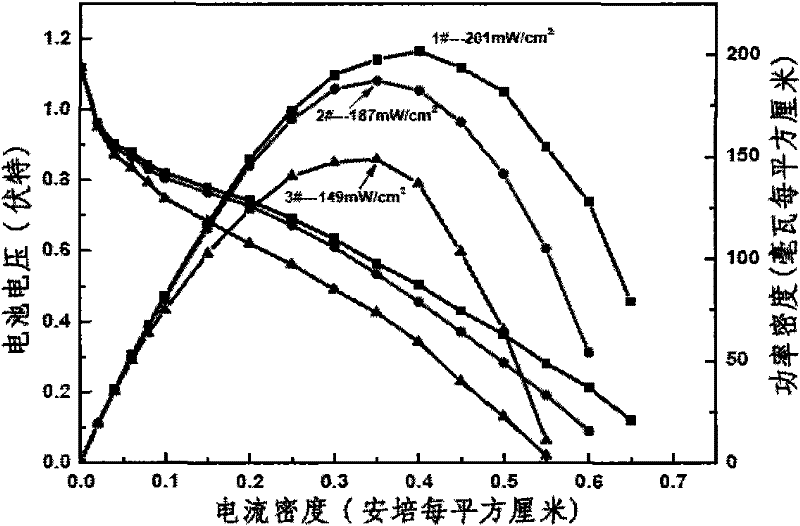

Embodiment 1

[0057] Dilute the 60% polytetrafluoroethylene emulsion to 2% with deionized water, then put Ballard EP40 (air permeability 4.5s / 100ml) into the prepared PTFE emulsion for 5 minutes, take it out, and dry it in an oven at 80°C After that, the second impregnation, drying and other treatments are carried out, and the mass content of PTFE in the carbon paper is calculated by weighing method until the mass content of PTFE reaches 20%. Finally, the carbon paper was sent to a 350°C roasting furnace for 40 minutes.

[0058] Take conductive carbon black 1.0g, add 25g ethylene glycol, after ultrasonic stirring 30min, according to the ratio of conductive carbon black: PTFE=1: 1, the 10% PTFE emulsion of calculated consumption is added in the slurry of conductive carbon black, continue Sonicate and stir for 30 min before use.

[0059] Fix the PTFE-treated carbon paper on the platform of the screen printing machine to ensure that the printing area is 150*200(mm 2 ), by adjusting the dista...

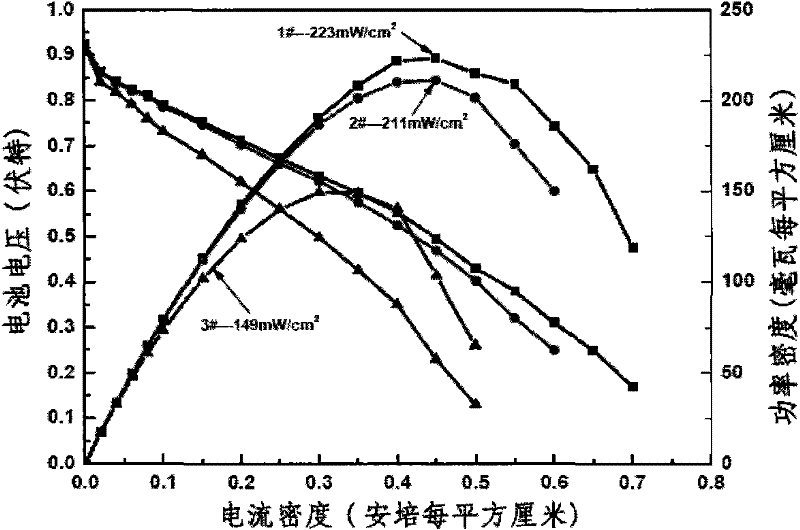

Embodiment 2

[0065] Dissolve and dilute polyvinylidene fluoride with a concentration of 60% to 2% with N,N-dimethylpyrrolidone, and then put Toray TGP-H-090 (air permeability 6.62s / 100ml) into the prepared PVDF solution Take it out after soaking for 5 minutes, dry it in an oven at 80°C, and then perform the second impregnation and drying treatment. The mass content of PVDF in carbon paper is calculated by weighing method until the mass content of PVDF reaches 20%. Finally, the carbon paper was sent to a 190°C roasting furnace for 40 minutes.

[0066] Take by weighing conductive carbon black (particle size is 30nm) 0.6g, add 30gNMP, after ultrasonic stirring 30min, according to the ratio of conductive carbon black: PVDF=6: 4, the 5% PVDF solution of calculated consumption is added in the slurry of conductive carbon black , continue to sonicate and stir for 30 minutes before use.

[0067] The transition hole layer and the microporous layer are prepared by spraying. Fix the PVDF-treated car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com